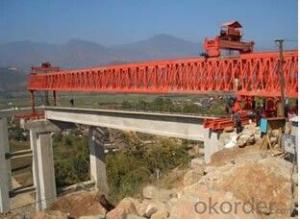

High-end Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

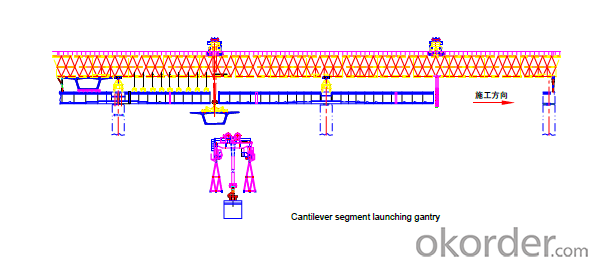

Cantilever segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: Detection and quality standard of bridge erecting machine

- Single girder bridge erecting machineThe utility model is characterized in that the hanging arm of the bridge is a box girder, and the front suspension is extended. The machine can be unloaded in the state of their own into the bridge, and then the front column straight, supported in front of the pier. When the beam (or the whole beam) moves along the boom, the boom is close to the beam. Bridge, the machine can automatically enter the bridge in the unloaded state, must first be the beam gantry crane with special transfer from the railway flat car special beam car, then the car rear end beam and the bridging machine for erecting machine in position, driving the jib crane will be two the beam lift along the arm forward, arrive at the bridge site off the beam. In order to adapt to the curved bridge, the boom of the machine can swing a little in the horizontal plane. The method of beam in place is the same as that of the double cantilever bridge erecting machine (beam or track). The machine has the advantages of: cancel the balance weight, no need to push the top of the locomotive, feeding beam does not need the bridge line, the degree of mechanization, safety performance has improved. The 130 - ton victory type bridging machine.

- Q: What is the technical parameter of 30m/100t fixed guide beam of bridge erector?

- Car (horizontal) walking speed (m/min) 3.15 3.15 3.15Bridge machine through hole velocity (m/min) 5.566Beam transport flat car speed (m/min) beam flat car speed 6.6m/min, return speed 13m/min (variable frequency speed)Deflection of work (mm) maximum deflection 706034Longitudinal forward cantilever deflection 800630350Adaptive bending radius (m) 350300200To adapt to the incline angle of 0~45 degrees 0~45 degrees 0~45Machine power ~104kw ~92kw ~77kw

- Q: How much is a bridging machine

- Bridge erection machine is mainly composed of steel structure, lifting, walking and other components, of which the proportion of steel structure

- Q: DJ180 bridge machine how to run?

- Two, concrete skew bridge girder erecting machine installation, before, during and after a leg wheel position, left and right wheels to staggered around, the distance can be calculated according to the skew angle, so that the leg wheel can run on the same horizontal track (for details please contact with the manufacturer).Three, bridging machine longitudinal movement to do all the preparatory work, requires a place, not allowed to stop halfway.

- Q: DJ180 bridge frame 40 m beam through the hole program.

- Beam transport,Motor vehicle and host alignment,

- Q: 2700t bridging machine assembly summary how to write

- Write the main content of the work, how to work hard, the results achieved, and finally put forward some reasonable proposals or new efforts.......Work summary is to let the superior know what you have to contribute, reflect the value of your work.

- Q: Bridging machine belongs to special equipment

- Pressure vessels (including gas cylinders, the same below), pressure pipes, elevators, lifting machinery, passenger ropeway, large recreational facilities and field (plant) special motor vehicles.

- Q: Bridging machine which consists of four parts

- H, electrical system including all electrical control and lighting.In addition, some underground scraper and throttle control hydraulic system. Hydraulic cable control system for electric underground scraper.

- Q: What are the advantages and disadvantages of the overhead bridge erecting machine compared to the lower bridge erecting machine

- Compared with the downward bridging machine, the upper bridge erecting machine does not need to be laid

- Q: 100 tons of bridge crane can lift 100 tons beam

- Need to load 10%. If you say that the 100t is the rated load of the bridge crane, there is no problem with hanging 100t weights.

Send your message to us

High-end Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords