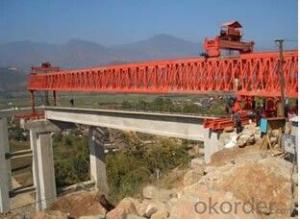

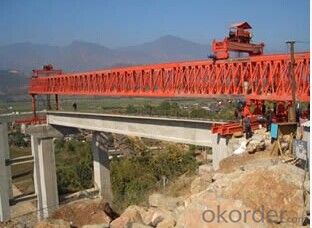

High-efficient Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

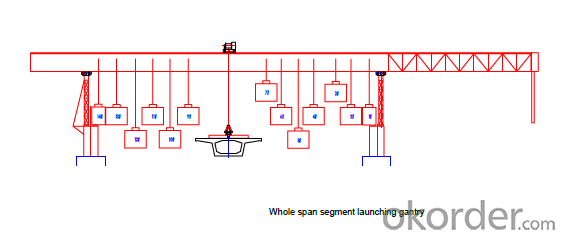

Whole span segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: What is the technical parameter of 30m/100t fixed guide beam of bridge erector?

- Project WJQ50/180~200 WJQ40/150~160 WJQ30/100~120Maximum lifting weight (T) 180150100Adaptive bridge span (m) 35~50 30~40 20~30

- Q: How much is a bridging machine

- Bridge erection machine is mainly composed of steel structure, lifting, walking and other components, of which the proportion of steel structure

- Q: Now the high-speed rail bridge frame span of the beam

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier

- Q: When does the bridge machine not belong to the gantry crane?

- But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift. Bridge machine is divided into the erection of highway bridges, conventional railway bridge, passenger dedicated railway bridge, etc..

- Q: What are the conventional lifting equipment? Bridge erecting machine is a kind of lifting equipment

- Belongs to the non-standard crane, exactly belong to special equipment

- Q: DJ180 bridge frame 40 m beam through the hole program.

- Beam and girder operation,Beam operation and falling beamBeam plate transverse movement and falling beam falling beam laying rail welding seam

- Q: The difference between double guide beam bridge machine and single beam bridge machine

- Single beam bridge machine:The single girder bridge girder erecting machine adopts a single bearing beam, and the bridge erecting machine is composed of a single main beam, a supporting leg, a hanging beam trolley, a moving mechanism, a transverse moving mechanism and an electric control system. Main girder structure generally adopts box type structure of light weight, high stability of the beam, the guide beam can be moved up and down, back and forth, transverse, achieve a heavily beam beam falling in place, continuous erection line, line, curve and other different types of bridges.

- Q: I would like to know the working principle of JQ IV 160t/40m bridging machine?

- JQ IV 160t/40m bridging machine:JQ bridge erecting machineType fourth, refers to the step type bridging machine160t - rated lifting weight 160t (2 x 80t)40m - allows the erection of the maximum span of 40m

- Q: Bridging machine which consists of four parts

- D, brake system - including parking brake, working brake;E, steering system - including the upper and lower hinge body, steering cylinder and the corresponding operating mechanism;F, the work system - including the bucket, the big arm, the rocker arm, the connecting rod and the correlation pin shaft;G, hydraulic system, including hydraulic system, hydraulic system, hydraulic system, hydraulic system, hydraulic system, hydraulic system, cooling system, lubrication system;

- Q: Purchase of special equipment, the use of units of evidence is the use of special equipment license?Where is the place of use or production?

- Specifically, it is located in the special equipment inspection institute (hereinafter referred to as the quality and Technical Supervision Department)

Send your message to us

High-efficient Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords