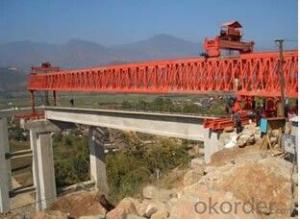

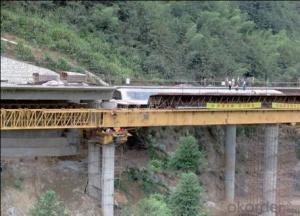

Launching gantry in span by span

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tyre trolley transfers the concrete segment to the rear of the launching gantry. The lifting trolley of the gantry lifts the concrete segment to the assembly position and the steeve hangs up the segment. After assembly, these segments tighten together with stressing wires, and the gantry put the beam on the pier and fulfill the construction of bridge segment. Based on the requirement of our client and the bridge conditions, the erection span and lifting capacity could be modified and customied for each machine.

530 ton Launching Gantry in span by span 100 ton Launching Gantry in span by span

General design data:

·Max span : 35m

·Max weight of each segment : 45ton (60ton)

·Max weight of span : 460ton(530ton)

·max longitudinal slope of bridge :±3%

·max transversal slope of bridge :±2%

·min horizontal radium : 600m(400m)

·Max wind speed on working condition : 22m/s

·Max win speed on static condition :35m/s

·Safety coefficient :≥2.5

·Stability factor of launching gantry :1.3

·Launching gantry’s fixing connection can be resistant emergencyconditions such as strong wind and typhoon.

·Temperature :from -10℃ to +40℃

·Relative humidity :90%

·The whole machine can move backward and forward for bridge erection.

- Q: What is the difference between bridge and gantry crane

- The general idea of installation: 1, laying gantry crane rail (generally the laying), but in the installation must be carried out before the crane on the track before detection, the gauge error is not more than 10 mm; 2, the installation of the cart on both sides of the parallelism, the verticality that can pull round pull line, diagonal, full justice etc. means of correction, (if the cart is not adjusted, rail gnawing will make you a headache to difficult adjustment) 3, lifting the legs together, and the connection, and the cable wind rope, a leg 4 rope hook (after loose ropes fixed rear legs will not pour down)

- Q: How much is a bridging machine

- The preliminary estimate can be calculated according to the weight of steel structure. Unit price of about 1.5~2 yuan / ton.

- Q: Such as Title ah.....I am sorry that the steel structure

- 84261120 bridging machine84261120 highway bridge erecting machine84269900 highway bridge erecting machine84798990 bridging machine

- Q: Bridging machine rack in the front beam can beam block and padded timbers, whether there is stress between them.

- After all, the larger the force of the structure of the structure is more secure, block contact area is easy to collapse angle, destruction.

- Q: I would like to ask what types of bridge machine

- There are also based on tonnage points, highway bridge machine general tonnage is relatively small, generally less than 300 tons. The railway bridge erecting machine, especially the high speed railway bridge erecting machine, has a relatively large tonnage, 450 tons and 900 tons. Some manufacturers of bridge machine can be used for public rail, this bridge is generally suitable for the erection of ordinary railway bridge.

- Q: Our original home is the height of the beam is now 3m to 2.6 of the beam is not to the bridge before the support leg height

- Bridge to re calculate the supporting force, and the Bridge Design Institute for inspection

- Q: Operating rules for bridge erecting machines

- Three, bridging machine longitudinal movement to do all the preparatory work, requires a place, not allowed to stop halfway.Four. When the bridge crane carries the concrete beam, the front leg part of the bridge crane is required to be fixed by the hand pulling block (5T).Five, when installing the bridge with the upper and lower longitudinal slope, the longitudinal displacement of the bridge erecting machine should be prevented from sliding. For example: the triangle iron for protection on wheels before and after, especially in the leg from the beam end is near, shift to the attention of control.

- Q: I would like to know the working principle of JQ IV 160t/40m bridging machine?

- JQ IV 160t/40m bridging machine:JQ bridge erecting machineType fourth, refers to the step type bridging machine160t - rated lifting weight 160t (2 x 80t)40m - allows the erection of the maximum span of 40m

- Q: Bridging machine belongs to special equipment

- November 2014, the State Administration of Quality Supervision announced a new revision of the "special equipment directory". Included in the catalog is "bridging machine".

- Q: What are the advantages and disadvantages of the overhead bridge erecting machine compared to the lower bridge erecting machine

- There is no good way to deal with the wind when the bridge erecting machine is in the lifting section

Send your message to us

Launching gantry in span by span

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords