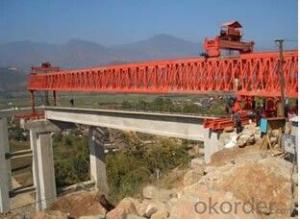

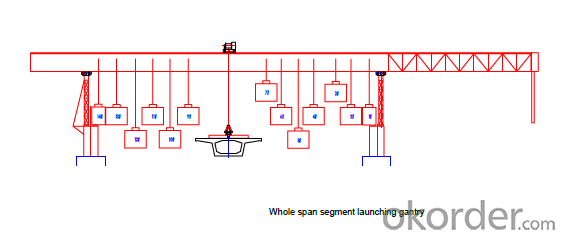

Easy Installation Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Whole span segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: Now the high-speed rail bridge frame span of the beam

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier

- Q: Safety slogan for bridge erecting machine

- Hello hello!Safety slogan for bridge erecting machine;1, safety first, prevention first!2, scientific development, security development!

- Q: What kind of machinery is the bridge? Is the bridge crane or bridge crane? What is the difference between the three?

- And there is walking on the beam, or called the longitudinal displacement. The biggest difference between the bridge erecting machine and the general overhead traveling crane is that it needs to go through the hole itself

- Q: Bridging machine rack in the front beam can beam block and padded timbers, whether there is stress between them.

- After all, the larger the force of the structure of the structure is more secure, block contact area is easy to collapse angle, destruction.

- Q: Weight of 120 ton bridging machine

- 0.65m/min (40 m and 120 tons beam) - 0.75m/min (30 m and 100 tons beam) 0.95m/min (30 m, 80 tons beam), the vertical speed of the crane: 6.6m/min 7, crane cross.

- Q: I would like to ask what types of bridge machine

- Bridge machine from the use of points, can be divided into highway bridge, railway bridge machine. Can also be divided according to the different structure, the name is more, for example, the auxiliary beam type, the whole frame, tunnel, etc.. Can also be based on the way to set the sub section of the assembly type, the whole hole, etc.

- Q: DJ180 bridge frame 40 m beam through the hole program.

- Beam and girder operation,Beam operation and falling beamBeam plate transverse movement and falling beam falling beam laying rail welding seam

- Q: Our original home is the height of the beam is now 3m to 2.6 of the beam is not to the bridge before the support leg height

- The front leg is to reduce a certain height. Do not know who you are using the bridge machine, and some of the front legs of the bridge machine can be dismantled section, and some have spiral support, so, but also with the design manufacturers, can not change their own. Once you have it, in case of any problems, the designer has no responsibility.

- Q: Above the highway bridge construction machine, in the case of the erection of the protective scaffolding, bridge construction can be opened to traffic

- Whether the bridge construction in the time of traffic, the key depends on your bridge machine instructions

- Q: Bridging machine which consists of four parts

- H, electrical system including all electrical control and lighting.In addition, some underground scraper and throttle control hydraulic system. Hydraulic cable control system for electric underground scraper.

Send your message to us

Easy Installation Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords