Triangular Form Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

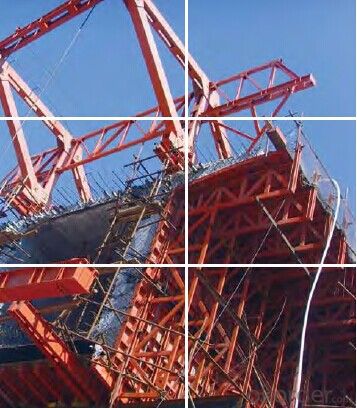

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

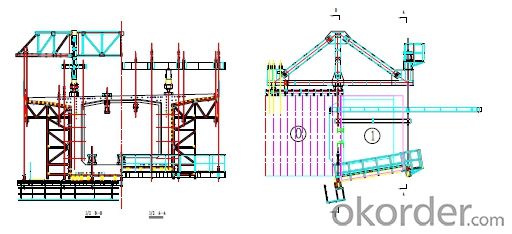

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: Hanging basket concrete pouring construction control points

- Management points:1 the concrete pouring on both sides of the beam should be symmetrical and balanced, and the unbalanced construction load should not be greater than the allowable value;2 concrete should be rapid, continuous construction, in the first pouring of concrete before the first pouring all completed;3 the bottom plate, the web and the roof are symmetrically layered, and the layer thickness should not be greater than 30cm;4 continuously change the height of the hanging basket in the process of concrete pouring;5 the quality of the installation of the prestressed channel, unobstructed inspection and plugging treatment;6 the vibration of concrete should meet the requirements of construction technology, it is appropriate to use high-frequency attachment vibrator with vibration;7 the temperature and air content of concrete in mold meet the design requirements;8 test specimens of concrete strength and elastic modulus.

- Q: I would like to ask you how to sort the hanging basket? What is the front fulcrum hanging basket

- According to the structure can be divided into the form of truss type (parallel chord, rhombic hanging basket, bowstring), cable-stayed type, type and mixed type steel four.

- Q: Construction of hanging basket hanging blue construction

- Wear safety helmet. Hanging basket construction is the key to the success or failure of cantilever casting, so the safety of the construction of hanging basket is critical, the construction must pay attention to the following matters:1, after the completion of the hanging basket, the class (Group) must be carried out after the suspension of the anchor system, fulcrum, sling, etc. to carry out a comprehensive and detailed inspection, to ensure that its force in line with the design requirements;2, cable belt, steel tape, steel straps are the main force, the material is special, absolutely can not carry out welding work on it, be careful not to burn the construction, cable belt and suspenders;3, the use of connectors and anchor bars, must be in the finishing of the rebar end of the paint marks, installation to ensure that the installation of steel in place, generally into the connector is not less than 8cm;

- Q: Hanging basket construction which test items

- Wire rope, safety rope, safety lock, some local arms also need to do.

- Q: What is the reference standard for hanging basket preloading

- Before 5.1. preloading, it is necessary to fasten the tension rod of the anchor system, especially the pull rod of the back pressure system and the front cross beam system, so that the tension force can be even.5.2. preloading, with 10 tons for a level two basket symmetrical at the same time, a total of 100 tons of load on each side, each load time must be very carefully observe the guide beam elevation, and paying close attention to the hanging basket system whether there is a significant change

- Q: In the construction of the bridge hanging basket, the temporary prestressing force is adopted in the closing section

- Almost the same procedure. Install jack, Jack extended a distance, not fully stretched

- Q: Operating rules for hanging baskets

- The above adjustment process, on-site construction management personnel and engineering and technical personnel must grasp the seven technical problems o A1 pay attention to the relationship between the turning point elevation, to coincide with the design of 2B1 through the side of the mold bottom to adjust the tension screw

- Q: The hanging basket is the main equipment of the cantilever pouring construction of the bridge

- The hanging basket is the main equipment of the bridge cantilever pouring construction, usually consists of five parts, namely: the main truss, lifting system, formwork system, walking system, anchor system

- Q: Hanging basket in the construction of the 2 block construction is also need to press it

- The main points of hanging basket construction:1 the installation elevation of the hanging basket should be in strict accordance with the designed value.2 reserved holes shall be accurate and shall not be allowed to bend.3 the pre tension of the hanging basket should be set according to the design.

- Q: What should be paid attention to in the construction of cast in place box girder of long span bridge hanging basket

- Attention should be paid to the construction of cast in place box girder of long span bridge hanging basket:1, pay attention to the pouring quality of concrete under anchor.2, the implementation of the whole process of construction survey and monitoring, should be entrusted with a professional qualification of the monitoring team for dynamic monitoring to ensure that the cast-in-place box girder elevation, axis and closure of the error to meet the requirements of the specification.3, beam bottom and Liang Ceyi temperature shrinkage cracks.

Send your message to us

Triangular Form Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords