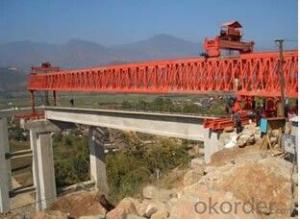

Easy Operation Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

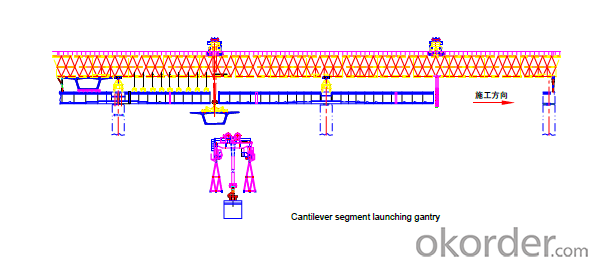

Cantilever segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: What is the technical parameter of 30m/100t fixed guide beam of bridge erector?

- Adapt to the maximum bridge longitudinal slope + 3 M + + + 3 + + 3Car rated speed (m/min) 1.5 1.5 1.5Car rated longitudinal walking speed (m/min) 4.28 4.28 4.28

- Q: How long will it take to set up the 30 - meter girder erecting machine on the highway

- Erection of 30 m girder bridge machine total length of 56-58 meters

- Q: What should be done before the erection of the bridge girder

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier. Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down

- Q: What kind of machinery is the bridge? Is the bridge crane or bridge crane? What is the difference between the three?

- Bridge crane is a bridge crane, bridge crane is also a crane, but not a bridge crane, the harsh conditions of its requirements

- Q: Bridging machine rack in the front beam can beam block and padded timbers, whether there is stress between them.

- After all, the larger the force of the structure of the structure is more secure, block contact area is easy to collapse angle, destruction.

- Q: Bridge machine has a sale of the code, used to query the bridge machine related information, is generally how much

- 0086 is the number, arrangement of crane factory sales department the orders of the factory will be mostly single beam double beam gantry crane bridge machine factory production of all types of single beam arranged together another individual plant and some other arrangement of course arrangement of rn: LD16T-22.5M 10120188rn 10120188 number meaning 16T 22.5M span single beam is a contract signed in December 2010 0188. Is the crane factory sales order arrangement number

- Q: What are the conventional lifting equipment? Bridge erecting machine is a kind of lifting equipment

- The standard is the Dalian crane factory out of a set of plans, covering each tonnage, span height are certain old. Non - standard is the new crane design specifications of the product, the old light a lot more, more powerful, can be based on the design of different tonnage span highly targeted. GB door machine is generally only state-owned factories to use, and now the market may account for seventy or eighty of the non - standard bar,

- Q: I would like to ask what types of bridge machine

- Bridge machine from the use of points, can be divided into highway bridge, railway bridge machine. Can also be divided according to the different structure, the name is more, for example, the auxiliary beam type, the whole frame, tunnel, etc.. Can also be based on the way to set the sub section of the assembly type, the whole hole, etc.

- Q: Bridge erecting machine belongs to portal or bridge crane

- The bridge is generally used for loading and unloading containers, and the door is generally used in the container crane.Bridging machine and the above 2 are not the same.

- Q: Bridging machine which consists of four parts

- H, electrical system including all electrical control and lighting.In addition, some underground scraper and throttle control hydraulic system. Hydraulic cable control system for electric underground scraper.

Send your message to us

Easy Operation Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords