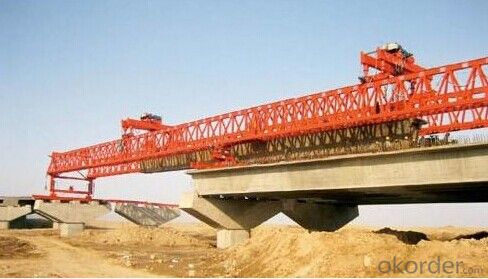

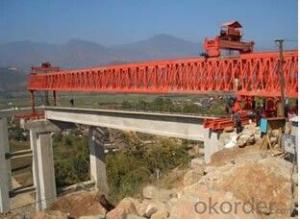

Efficient Cantilever Segment Launching Gantry in China

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

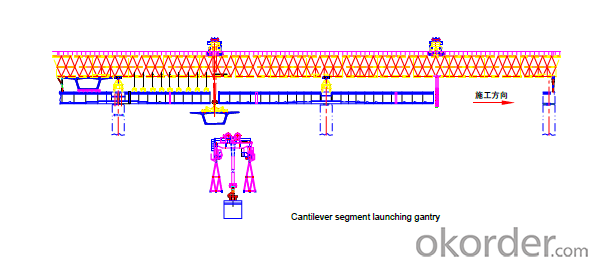

Cantilever segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: How long will it take to set up the 30 - meter girder erecting machine on the highway

- It depends on the situation. Different manufacturers have different. The utility model is provided with a counterweight guide hole which is provided with a counterweight guide hole. Overall between 38 meters to 60 meters to see what you need.

- Q: Such as Title ah.....I am sorry that the steel structure

- 84261120 bridging machine84261120 highway bridge erecting machine84269900 highway bridge erecting machine84798990 bridging machine

- Q: Bridge erection of a small box girder of long time

- Generally, that is, from the beam to the beam in place is 20 minutes

- Q: What kind of machinery is the bridge? Is the bridge crane or bridge crane? What is the difference between the three?

- And there is walking on the beam, or called the longitudinal displacement. The biggest difference between the bridge erecting machine and the general overhead traveling crane is that it needs to go through the hole itself

- Q: The difference between the bridge erecting machine and machine

- Bridging machine and bridging machine are actually similar.

- Q: Bridge machine has a sale of the code, used to query the bridge machine related information, is generally how much

- 0086 is the number, arrangement of crane factory sales department the orders of the factory will be mostly single beam double beam gantry crane bridge machine factory production of all types of single beam arranged together another individual plant and some other arrangement of course arrangement of rn: LD16T-22.5M 10120188rn 10120188 number meaning 16T 22.5M span single beam is a contract signed in December 2010 0188. Is the crane factory sales order arrangement number

- Q: Bridge erecting machine belongs to portal or bridge crane

- Bridging machine belongs to the gantry or bridge crane? Encountered such problems, I suggest that we look directly at [Special Equipment Directory] will know, that is an authoritative explanation ah!Bridge crane belongs to bridge crane.Basis: [Special Equipment Directory]Special equipment catalog:Category: Hoisting MachineryBridge craneBridging machine

- Q: How does the bridging machine work?

- Then, the beam is placed between the first and the second piers of the bridge pier by the conveying mechanism, is generally a few beams form a bridge, a bridge frame can make bridge machine move to between the first and second frame pier pier next beam. You'd better take a look at the actual construction process.

- Q: Bridging machine which consists of four parts

- D, brake system - including parking brake, working brake;E, steering system - including the upper and lower hinge body, steering cylinder and the corresponding operating mechanism;F, the work system - including the bucket, the big arm, the rocker arm, the connecting rod and the correlation pin shaft;G, hydraulic system, including hydraulic system, hydraulic system, hydraulic system, hydraulic system, hydraulic system, hydraulic system, cooling system, lubrication system;

- Q: What are the advantages and disadvantages of the overhead bridge erecting machine compared to the lower bridge erecting machine

- High lifting height, easy installation. But in the transition to the higher requirements of the road (height, width, bearing capacity, etc.).

Send your message to us

Efficient Cantilever Segment Launching Gantry in China

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords