Form Traveler

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Rhombic Traveler

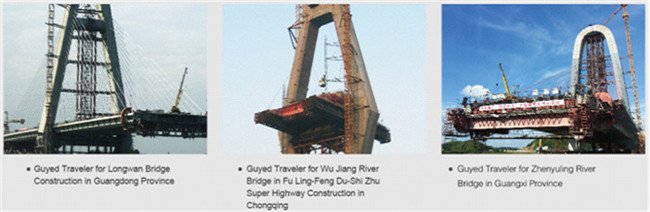

2.Guyed Traveler

3.Triangle Traveler

4.Through Supported Traveler

5.Normal Traveler

Products Introduction & Application:

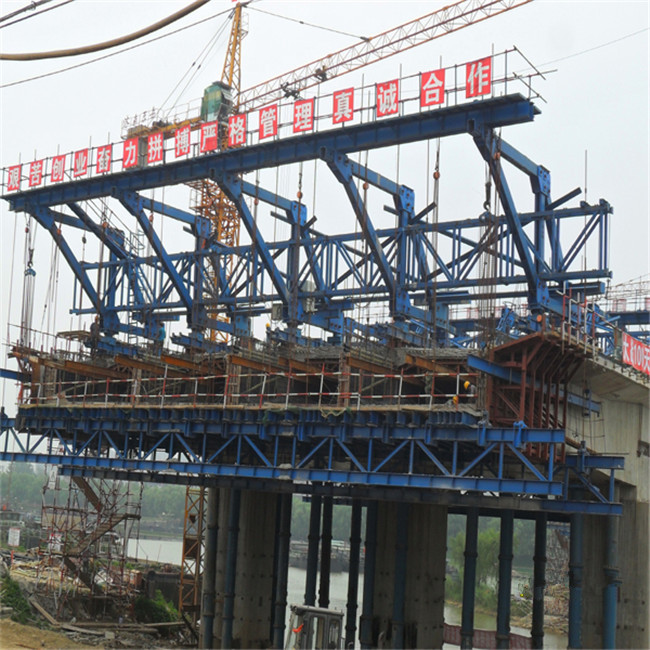

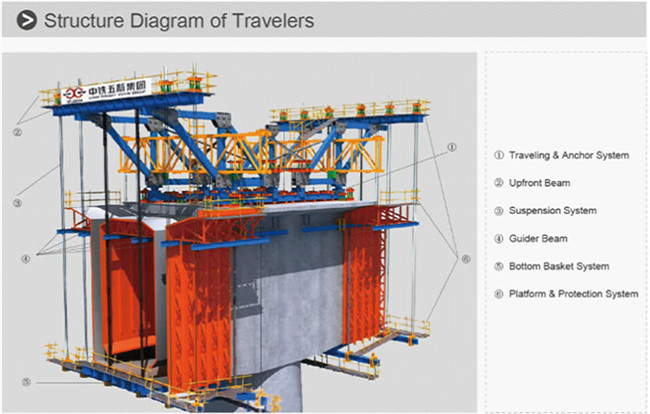

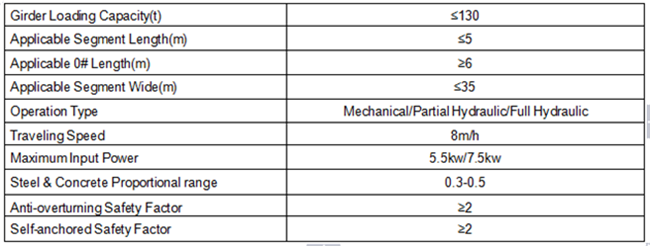

Form traveler is the major equipment used in cantilever construction. The product we developed is consist of main girder system, traveling system, anchor system, bottom basket system, suspension system, platform & protection system, formwork system, hydraulic system(optional) and so on. All the parts are self-contained, interdependent and interrelated, already awarded over 20 authorized patents.

In order to improve universality and utilization, reduce purchasing cost, and enhance security & reliability, we provide the series service of “designing, detecting, renting and constructing form traveler service as well as technical assistance & training.” Today 800 T-structure form travelers can be provided for renting service.

Projects:

- Q: Construction scheme of hanging basket

- Each pier is equipped with 23 cantilever sections: 5*2.5m + 5*3.0m + 5*3.5m + 8*4.0m. Beam length of 4.0m, maximum weight 156 tons. The cross section of the box girder: the width of the top plate is 15.42m, the width of the web is 7.5m, and the height of the beam is changed from 0 8.8m to the 3.0m of the block 23 according to the two parabola.

- Q: What are the key processes of hanging basket construction

- The key process of hanging basket construction: 1, No. 0 block support (support) frame construction; 2, support and temporary consolidation system construction; 3, hanging basket construction

- Q: I would like to ask: how to choose the kind of hanging basket? Do their own basket design and production for 2 years, but do is diamond, triangle hanging basket and diamond hanging basket, etc.

- The other is to fit the actual, anyway, so many hanging baskets did not change to the scene. Some even have to cut the injured all over the body...... Heartache.

- Q: I'm looking for lowest service charge and also prevention of loss or theft. I know actual Swedish Kronas would be best but is it better to use traveler's cheques or credit ot atm card?Thanks

- Bring your card (visa, mastercard) you can pay pretty much everywhere with card there.

- Q: Hanging basket construction must be both sides at the same time construction? Are there any rules? What is the norm?

- Please rest assured that the calculation of the load of the bridge structure is huge, just hanging basket this little temporary construction load is not a piece of cake!Only from the point of gravity load on the bridge, there is no problem. But whether the requirements of the construction process, construction organization, or starting or starting from the schedule to rush period, it should be different.

- Q: Why from the beginning of cantilever beam pouring cantilever end?

- General joints are the final processing, in accordance with this principle, you can infer the front end (Yuan Duan) pouring, and finally deal with the old and new material seam problem

- Q: Are there any hanging baskets on both sides of the hanging beam 0

- First, the height of the test results. In line with the requirements do not pre pressure, followed by hanging basket construction 0# block is the most important, pre pressure pouring.

- Q: How is the prestressed steel bar in the hanging basket method? Is the length of each section of the tension of the prestressing tendons, or tensioned T - shaped steel beam length of prestressed tendons?

- The general construction of prestressed concrete box girder with cantilever hanging basket construction scheme, the box girder hanging basket, formwork, reinforced after installation, concrete pouring, the concrete reaches the design strength value after tensioning the beam segments each segment between the prestressed tendons (tendons connected according to the design of short or long beam the layout of the beam.) after grouting, demolition template

- Q: Combined with the hanging basket pouring construction process, the paper puts forward the quality control points and methods of hanging basket continuous casting box girder

- The hanging basket in the process of walking, the two should be a walking anchor beam as a whole, to prevent the process of walking anchor beam deviation affect the normal walking, if found walking anchor beam walking by right, should immediately stop walking, the first of its position is adjusted during walking, should additional insurance is hard on walking anchor, anchor in order to adjust the position of the beam;After hanging blue in place, should immediately after the anchor, the box and the top of the box sling anchor, it is strictly prohibited to use internal and external guide beam frame for box beam concrete construction.

- Q: Construction technology of hanging basket construction:

- The construction of a steel cable-stayed bridge, most of the factory welding process, transported to the site, with the crane as a whole lifting, or block lifting, in place after the formation of high-strength bolts.Two construction of concrete cable-stayed bridge with cast-in-place and precast assembly and other combinations of construction technology. 1 the installation elevation of the hanging basket should be in strict accordance with the designed value.

Send your message to us

Form Traveler

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords