Drain Agricole 100 Avec Géotextile - Pet Needle Punched Nonwoven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | export standard packing,or according to customer's request |

| Delivery Detail: | 20days after your order confirmed |

Specifications

Road Construction

1.high quality geotextiles

2.ISO9001: 2008 certified

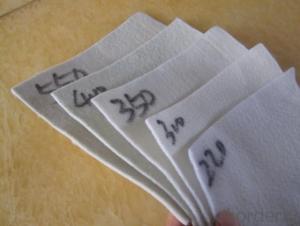

3.Short or Long fiber needle punched nonwoven

Introduction:

Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drain.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

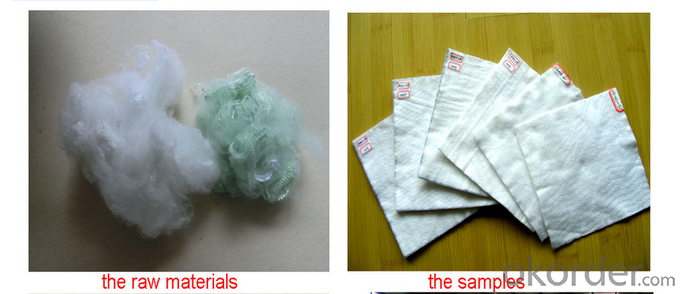

Geotextiles are availabel as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commenly used to separate layers like clay and drainage and to protect liner from damage.

Features:

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction.

Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

Manufactured using a randomly orientated web to proide completely isotropic properties,ensuring that high strength is not limited to a single direction.

Excellent uniformity with high permeability and low pore size for soil filtration.

Supplied to a maximum width of 6.5mts,ensuring minimum waste over large construction areas.

100% polypropylene or polyester staple fibers ,needle punched and random network formation.

UV and rot resistant and biological degradation resistant.

Applications:

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.Some commen uses of the material includes the following:

Road stabilization applications

Roofs

Civil applications

Railway work

Landfill lining

Trenches

Dams

Fitration under rip rap and rocks

Environmental applications

Packaging & Shipping

Geotextile rolls are packed in woven cloth after inspection, then loaded in container by forkman.

FAQ:

♦ Payment terms: by T/T or L/C |

♦ MOQ:2000 SQM |

♦ If you are interested in our products ,pls advice me the technical index,product weight etc,the more information the better..... |

- Q: How do geotextiles help in preventing the growth of weeds?

- Geotextiles help in preventing the growth of weeds by acting as a physical barrier between the soil and the environment. These synthetic fabrics are placed over the soil, suppressing weed growth by blocking sunlight, which weeds need for photosynthesis. Geotextiles also inhibit weed root penetration, preventing them from establishing a strong foothold in the soil. Additionally, the fabric allows water and nutrients to pass through, promoting healthy plant growth while suppressing weed development.

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles are permeable fabrics that can be placed between different soil layers to prevent mixing and maintain their distinct properties. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This separation helps in enhancing the stability and performance of the soil layers, reducing the risk of settlement and maintaining the integrity of the construction project.

- Q: What are the key considerations for geotextile installation in high temperature environments?

- The key considerations for geotextile installation in high temperature environments include selecting geotextiles that are resistant to thermal degradation, ensuring proper anchoring and securing of the geotextiles to prevent movement or displacement, and considering potential expansion and contraction of the geotextiles due to temperature fluctuations. Additionally, it is important to assess the long-term performance and durability of the geotextiles under high temperature conditions and to monitor their performance regularly to detect any signs of degradation or failure.

- Q: Can geotextiles be used in the construction of landfills?

- Yes, geotextiles can be used in the construction of landfills. Geotextiles are often used as a barrier or separator material in landfill construction to help with soil erosion control, filtration, and drainage. They can also enhance the stability and overall performance of the landfill by preventing the mixing of different layers and providing reinforcement.

- Q: What is the use of the black network when the shop is paved?

- It is geogrid, can enhance the overall strength of the roadbed, from the role of tensile, mostly polyethylene materials.

- Q: Are geotextiles suitable for use in groundwater remediation systems?

- Yes, geotextiles are suitable for use in groundwater remediation systems. Geotextiles can act as a barrier to prevent the migration of contaminants and provide filtration for groundwater. They can also enhance the effectiveness of other remediation methods by improving the distribution and retention of remedial agents. Additionally, geotextiles are durable, cost-effective, and environmentally friendly, making them a suitable choice for groundwater remediation systems.

- Q: Can geotextiles be used in canal lining applications?

- Yes, geotextiles can be used in canal lining applications. Geotextiles provide effective erosion control, drainage, and filtration properties, making them suitable for lining canals to prevent soil erosion and improve water flow.

- Q: How do geotextiles interact with other geosynthetic materials?

- Geotextiles interact with other geosynthetic materials by complementing their functions and enhancing their performance. They can be used in conjunction with geogrids, geomembranes, or geocomposites to provide additional reinforcement, filtration, separation, or drainage capabilities. Geotextiles can be layered between different geosynthetic materials to create a composite system that addresses multiple engineering requirements in various civil and environmental applications.

- Q: How are geotextiles used in coastal engineering?

- Geotextiles are commonly used in coastal engineering to stabilize and protect coastal areas from erosion. They are deployed as a barrier along shorelines to prevent sediment migration, provide slope stabilization, and promote vegetation growth. Geotextiles also aid in the filtration and drainage of water, reducing wave energy and preventing scour.

- Q: How do geotextiles improve the performance of foundations?

- Geotextiles improve the performance of foundations by providing reinforcement, filtration, and separation functions. They increase the load-bearing capacity of the soil, distribute the load more evenly, and prevent the mixing of different soil layers. Additionally, geotextiles help to drain excess water, control soil erosion, and protect the foundation from potential damage.

Send your message to us

Drain Agricole 100 Avec Géotextile - Pet Needle Punched Nonwoven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords