Geotextile for French Drain - Non Woven Geotextiles with Needle Punch 100g

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Geotextile Application

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

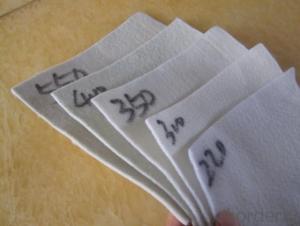

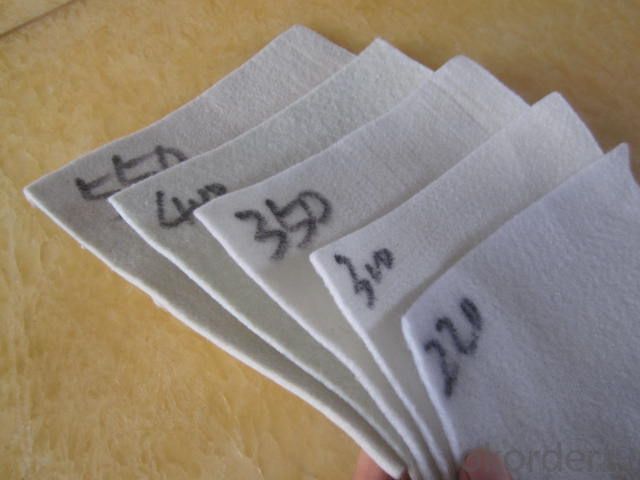

Geotextile Specifications:

Weight: 100GSM-1500GSM

length: 50m-100m

width:1m-8m

material:100%PET

Packaging Details:pp woven bags or at your request

Delivery Detail:15 days

GeotextileProperty:

1. Super high strength, ultralight, high resistance.

2. Resistance to chemical erosion, excellent water resistance.

3. Abrasion resistant.

4. Excellent anti-aging and anti-UV property, good weather fastness.

FAQ:

Q: What kind of payments could you support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with soil confinement in erosion control bags?

- Geotextiles play a crucial role in soil confinement within erosion control bags by acting as a barrier that prevents the soil from escaping while allowing water to pass through. They provide structural stability to the bag, preventing it from collapsing or shifting, thereby maintaining the shape and effectiveness of the erosion control structure. Additionally, geotextiles help in distributing the load evenly across the bag, minimizing stress on the soil and enhancing its ability to resist erosion.

- Q: How do geotextiles aid in the reduction of pore water pressure?

- Geotextiles aid in the reduction of pore water pressure by providing a barrier that allows water to flow through while preventing the migration of fine particles. This allows for efficient drainage, preventing the build-up of excess pore water pressure within the soil or ground, ultimately reducing the risk of soil liquefaction or instability.

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing additional reinforcement and stability. They act as a filtration layer, preventing soil erosion and allowing water to pass through while retaining fine particles. Geotextiles also enhance the strength and durability of geotubes by distributing loads evenly and reducing the risk of punctures or tears.

- Q: Can geotextiles be used in the protection of bridge abutments?

- Yes, geotextiles can be used in the protection of bridge abutments. Geotextiles are commonly used in civil engineering projects to provide erosion control, soil stabilization, and filtration. When applied to bridge abutments, geotextiles help to prevent soil erosion, reduce water infiltration, and enhance the overall stability and durability of the structure.

- Q: What are the different installation guidelines for geotextiles in reinforcement projects?

- There are several guidelines to follow when installing geotextiles in reinforcement projects. Firstly, ensure that the subgrade is properly prepared and compacted before laying the geotextile. Next, carefully unroll the geotextile and secure it in place using stakes or by embedding it in the soil. It is important to overlap adjacent rolls of geotextile by at least one foot to ensure proper coverage. Additionally, avoid wrinkles or folds in the geotextile as they can reduce its effectiveness. Finally, cover the geotextile with a layer of soil or aggregate to protect it from damage and to provide additional reinforcement.

- Q: What are the different types of geotextile installation equipment?

- Some different types of geotextile installation equipment include geotextile rollers, geotextile spreaders, geotextile stitchers, and geotextile tensioners. These tools are used to properly position, secure, and connect geotextiles during installation for various applications such as erosion control, drainage, and reinforcement.

- Q: How do geotextiles contribute to erosion control on slopes?

- Geotextiles help in erosion control on slopes by providing a protective barrier that prevents soil erosion caused by water runoff. These synthetic fabrics are placed on the slope's surface or within the soil to stabilize it, reduce the velocity of water, and promote filtration. This helps to retain the soil in place, allowing vegetation to establish and roots to penetrate, thus reinforcing the slope and preventing erosion.

- Q: How do geotextiles help in preventing shoreline erosion?

- Geotextiles help in preventing shoreline erosion by acting as a barrier against soil erosion caused by water movement. They are placed along the shoreline to stabilize the soil, reduce wave energy, and prevent sediment from being washed away. The geotextiles trap sediment and allow water to pass through, which helps to build up and maintain the beach or shoreline, ultimately protecting it from erosion.

- Q: What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as the material type, weight, permeability, tensile strength, and filtration properties. The geotextile material should be appropriate for the specific drainage application and capable of withstanding the anticipated loads and environmental conditions. It should also have a specific weight or thickness to ensure proper performance. The permeability of the geotextile is important to allow water to flow through while preventing soil particles from clogging the drainage system. Tensile strength is a crucial factor as it determines the geotextile's ability to withstand installation stresses and potential loads. Lastly, filtration properties are essential to retain soil particles while allowing water to pass through.

- Q: Can geotextiles be used in retaining wall construction?

- Yes, geotextiles can be used in retaining wall construction. Geotextiles are commonly employed as a material for soil reinforcement and stabilization. They can be used in retaining walls to enhance the strength and stability of the structure by preventing soil erosion, improving drainage, and providing additional support to the soil behind the wall.

Send your message to us

Geotextile for French Drain - Non Woven Geotextiles with Needle Punch 100g

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords