Pet Needle Punched Non Woven Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Pet Needle Punched Non Woven Geotextile Description:

Pet Needle Punched Non Woven Geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

Main Features of the Pet Needle Punched Non Woven Geotextile :

1)Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls.

At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely

2)Separations:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, different dam materials.

It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

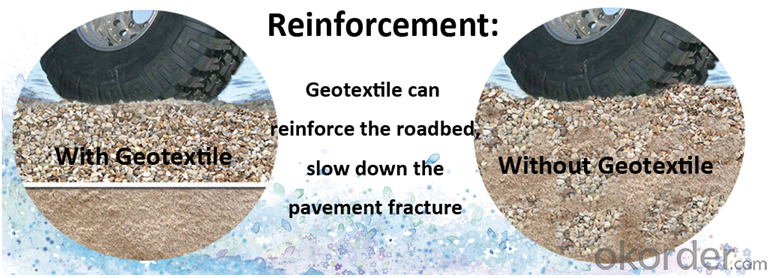

3) Adding muscle:

The highway, railway of retaining wall, slope protection, etc in which distributes the earth stress,

prevents the side-displacement of the earth body and improves the earth body stability.

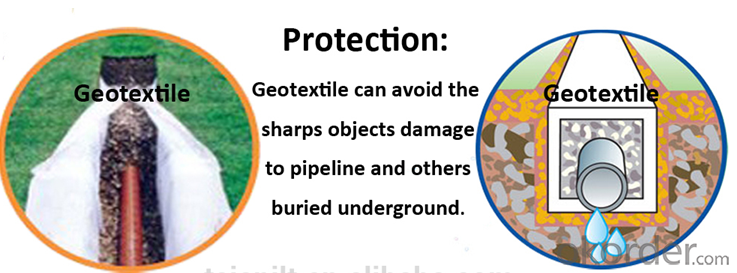

4) Protections

It prevents the bank from being washed out, protects the bank and the bottom,

prevents the water and soil from being washed away

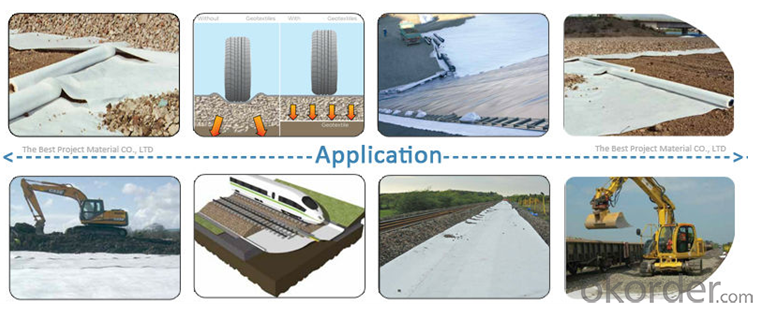

Pet Needle Punched Non Woven Geotextile Images

Pet Needle Punched Non Woven Geotextile Specification:

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

6) Certificate: CE/ISO9001 , ISO14001

7) Manufacturing method: nonwoven / woven

8) The Biggest geotextile manufacturer/factory in China for many years

| No. | Item | Unit | Standard Specification | ||||||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

| 1 | Weight Deviation | g/m² | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

| 2 | Thickness ≥ | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 |

| 3 | Width Deviation | % | -0.5 | ||||||||||

| 4 | Breaking Strength | KN/M | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 |

| 5 | Breaking Elongation | % | 25-100 | ||||||||||

| 6 | CBR Tear Strength ≥ | KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 |

| 7 | Sieve Size | mm | 0.07--0.2 | ||||||||||

| 8 | Vertical Permeability | N/5cm | K x(10-1 --10-3) | ||||||||||

| 9 | Tear Strength ≥ | KN | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Seepage geotextile and impervious geomembrane

- It is generally believed that the individual geotextile does not have the anti-seepage effect, the main assessment index is the permeability coefficient, the general geotextile coefficient is higher than the ordinary soil, about 0.01-0.001 look, but the geotextile and rubber, Asphalt, plastic combination will form a water-impermeable composite, anti-seepage effect increased by 10 times, and asphalt, rubber combined into a waterproofing membrane such as sbs, etc., and plastic is generally polyethylene, polyvinyl chloride, eva (standard name is Geomembrane) is a combination of impermeable geomembrane or composite geomembrane, because the composite white geotextile outside the protective effect, so the project is also called impermeable geotextile. Therefore, the two are essentially not much difference, but the argument is different. Waterproof board is also called geomembrane, customary to> 0.8mm thick geomembrane called waterproof board, & lt; 0.8mm called geomembrane, it is based on high molecular polymer as raw material made of impermeable material , Divided into homogeneous waterproof board and composite waterproof board

- Q: How do geotextiles contribute to the durability of civil engineering structures?

- Geotextiles contribute to the durability of civil engineering structures by providing reinforcement, filtration, and separation. They act as a barrier against soil erosion, increase the load-bearing capacity of soil, and offer protection against water seepage. These functions help to prevent structural damage, enhance the lifespan of the infrastructure, and ensure its long-term stability.

- Q: How do geotextiles prevent soil contamination?

- Geotextiles prevent soil contamination by acting as a barrier that separates the soil from potentially harmful substances, such as pollutants or contaminants. It helps to filter and retain these substances, preventing them from leaching into the soil and affecting its quality. Geotextiles also aid in erosion control, reducing the risk of soil contamination caused by sediment runoff.

- Q: What are the key factors affecting the filtration performance of geotextiles?

- The key factors affecting the filtration performance of geotextiles include the pore size and distribution of the fabric, the thickness and permeability of the material, the hydraulic gradient or pressure difference across the geotextile, and the presence of any clogging or blockage due to soil particles. Other factors such as the type of soil, the duration of filtration, and the geotextile's chemical and physical properties can also influence its performance.

- Q: Geotextile vertical and horizontal stretching the gap is too much how to adjust

- Geotextile longitudinal and horizontal tensile strength of the gap adjustment, mainly in the carding, laying the net, drawing three links to control, sort out the ratio of Daofu regulation, shop layer, shop curtain speed ratio, Sticks, input and output differences, and so are the cause of a huge gap, the other fiber curl, and so is the key. For the above adjustment, you will find the law. In order to geotextile stretch the vertical and horizontal adjustment equal.

- Q: Can geotextiles be used in wetland restoration projects?

- Yes, geotextiles can be used in wetland restoration projects. Geotextiles, which are permeable fabrics made from synthetic materials, can serve multiple purposes in wetland restoration. They can be used to stabilize soil, control erosion, and filter sediment, while still allowing water and nutrients to pass through. By using geotextiles, wetland restoration projects can effectively manage water flow, enhance vegetation growth, and protect against erosion, ultimately aiding in the successful restoration of wetland ecosystems.

- Q: Geotextile special staple fiber where needed

- How much is a ton?

- Q: What are the applications of geotextiles in landscaping?

- Geotextiles have various applications in landscaping, including erosion control, soil stabilization, and weed suppression. They can be used to prevent soil erosion on slopes, retain soil in embankments, and enhance the stability of retaining walls. Geotextiles also act as a barrier to prevent weed growth, reducing the need for herbicides. Additionally, these textiles can be employed in drainage systems to improve water filtration and prevent soil compaction. Overall, geotextiles provide valuable solutions for improving the sustainability and longevity of landscaping projects.

- Q: How do geotextiles contribute to land reclamation projects?

- Geotextiles contribute to land reclamation projects by providing erosion control, soil stabilization, and drainage solutions. They act as a barrier between the underlying soil and overlying materials, preventing soil erosion caused by wind or water. Geotextiles also help stabilize the soil, allowing vegetation to grow and preventing the formation of unstable slopes or embankments. Additionally, they aid in efficient drainage, ensuring proper water flow and preventing waterlogged conditions that could hinder the reclamation process. Overall, geotextiles play a crucial role in land reclamation projects by enhancing the stability and productivity of reclaimed land.

- Q: What is the geotextile for ditch drainage?

- Is to use ordinary polyester staple geotextile, for the role of water filtration. Huazhi geotextile materials, geotextile solution manufacturers

Send your message to us

Pet Needle Punched Non Woven Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords