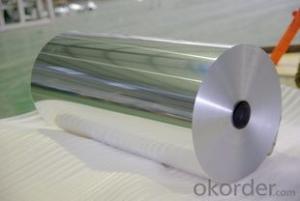

Perforated Rolls Aluminum Sheets for Medical and Food Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium blister foil manufacture in China,Sichuan Hui Li Industry Co.,Ltd supply pharmaceutical packaging foil as bellow:

aluminium foil,20my/30my, hard tempered, dull/bright side, one side primered for printing, the other side thermo seal lacquered against PVC/PVDC, supplied in reels, unprinted or printed according to artwork provided, max 4 colour text,Max width:800mm,roll length is 1200m,or per client’s request.

Application:

Excellent properties such as of anti-oxygen, moisture-proof, leak-proof, antipollution, etc.

High stability and sanitation.

Heat-sealing with PVC or PVDC sheet.

Blister packages for pharmaceutical products such as capsules and tablets, pill, pastille, small-size food, candy, etc.

- Q: This question asks about the various types of aluminum sheets that are commonly used for roofing purposes, including their specific applications and characteristics.

- <p>Aluminum sheets used for roofing come in various types, each with unique properties and applications. The main types include: 1) Corrugated Aluminum Sheets: Known for their strength and durability, these are often used in commercial and industrial roofing due to their ability to withstand harsh weather conditions. 2) Standing Seam Aluminum Sheets: These provide a sleek, clean look and are favored for their water-resistant properties, making them ideal for residential and architectural applications. 3) Flat Aluminum Sheets: Offer a smooth surface finish and are used where a uniform appearance is desired. 4) Perforated Aluminum Sheets: These have small holes that allow for ventilation, reducing heat build-up and are used in areas requiring natural light and air circulation. 5) Embossed Aluminum Sheets: With a textured surface, they provide added rigidity and are used in both residential and commercial settings for their aesthetic appeal. Each type is chosen based on the specific needs of the roofing project, such as design, weather resistance, and longevity.</p>

- Q: Are aluminum sheets suitable for HVAC ductwork?

- Indeed, HVAC ductwork can be made using aluminum sheets. The lightweight and durable characteristics of aluminum make it a favored option for ductwork. Its resistance to corrosion is crucial in HVAC systems where moisture and condensation are prevalent. Moreover, aluminum ductwork exhibits excellent thermal conductivity, enabling efficient heat transfer. Furthermore, the simplicity of working with aluminum sheets renders installation and maintenance relatively easy. Ultimately, aluminum sheets guarantee dependable performance and energy efficiency, making them a trustworthy selection for HVAC ductwork.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q: Can aluminum sheets be soldered?

- No, aluminum sheets cannot be soldered using traditional soldering methods. However, alternative techniques such as specialized soldering alloys, fluxes, or adhesives can be used to join aluminum sheets together.

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: Can 101 aluminum sheets be painted with automotive-grade finishes?

- Yes, 101 aluminum sheets can be painted with automotive-grade finishes.

- Q: What is the weight of an aluminum sheet?

- Depending on its dimensions and thickness, an aluminum sheet may have varying weights. Due to its lightweight nature, aluminum sheets generally possess lower weights in comparison to other metals. In order to determine the weight of an aluminum sheet, it is necessary to possess knowledge regarding its length, width, and thickness. By multiplying the dimensions with the density of aluminum (2.7 g/cm³ or 0.0975 lb/in³), one can ascertain the estimated weight of the sheet.

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: Are aluminum sheets suitable for thermal insulation?

- No, aluminum sheets are not suitable for thermal insulation on their own. While aluminum is a good conductor of heat and electricity, it does not have good insulating properties. In fact, aluminum sheets can actually transfer heat instead of blocking it, making them ineffective for thermal insulation purposes. For proper thermal insulation, materials with low thermal conductivity, such as fiberglass, mineral wool, or foam boards, are commonly used. These materials are designed to trap air or create a barrier that reduces the transfer of heat, ensuring effective insulation.

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

Send your message to us

Perforated Rolls Aluminum Sheets for Medical and Food Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords