Perforated Aluminum Foil Sheets for Collapsible Aluminium Tubes Slug/Circles

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

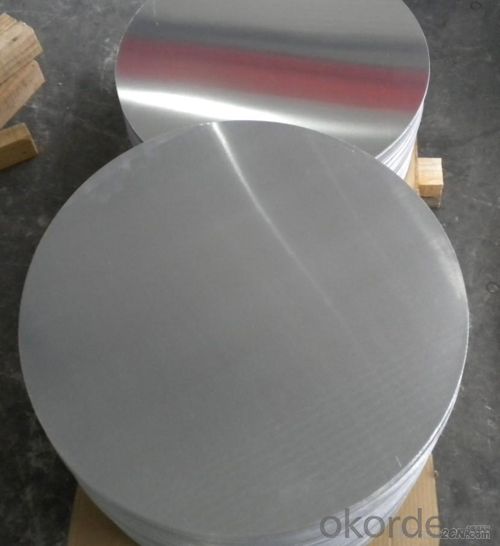

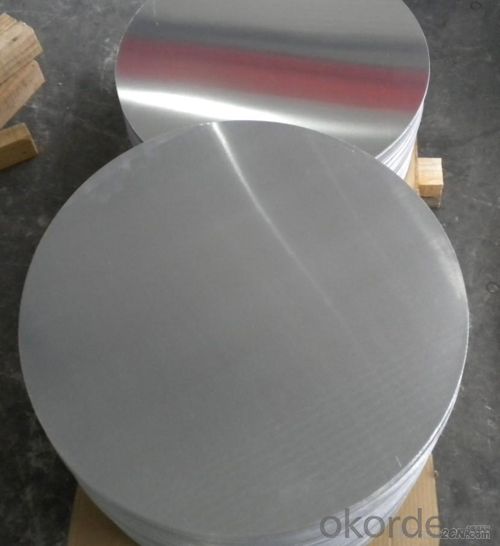

1. Description of Collapsible Aluminium Tubes Slug/Circles

Alloy: 1050, 1070, 1100, 3003, etc

Thickness: 0.5mm~4mm

Temper: O, H14

Diagonal: 100mm - 1200mm

2. Application of Collapsible Aluminium Tubes Slug/Circles

Aluminium Circle is widely used for kitchen wares including fried pans, non-sticky pans, cooking pots, hard anodize cook ware, pressure cooker and house hold utensils etc.

3. Feature of Collapsible Aluminium Tubes Slug/Circles

Aluminium Circle has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Collapsible Aluminium Tubes Slug/Circles

6. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q: I'm 17 and it has been very hard finding a deodorant that makes me stop sweating. I told my dad I wanted to get Ban or Mitchum cause the percentage of Aluminum is very high. He said the Aluminum in deodorant has links to alzheimers, is that true? Also my sister said I could just scrub with soap morning and night, use regular deodorant without antipersperant and that would make me stop sweating too. But since i'm a teenager and my hormones are still weird would that be strong enough to stop sweat?

- aluminum oxide in antipersperant does lead to alzheimer's, yes. but antiperspirant is not deodorant, and deodorant does not contain aluminum. sweating is a natural bodily function. if you need to sweat, sweat. it's odor that should bother people.

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular material choice for HVAC applications due to its many advantageous properties. It is lightweight, making it easier to handle and install. Aluminum is also highly resistant to corrosion, which is crucial for HVAC systems that are exposed to moisture and varying temperatures. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer. This makes it ideal for heat exchangers and other components in HVAC systems. Overall, aluminum sheets are a reliable and durable option for HVAC systems.

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets differs based on the specific alloy employed. On average, aluminum exhibits a coefficient of thermal expansion of around 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). Consequently, with each degree rise in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It should be emphasized that this figure might vary slightly among diverse grades and alloys of aluminum.

- Q: What is the price range of aluminum sheets?

- The price range of aluminum sheets can vary depending on various factors such as the size, thickness, and grade of the sheet, as well as the supplier and market conditions. Generally, aluminum sheets can range in price from around $0.50 to $5 per square foot. Thinner sheets or lower-grade aluminum may be on the lower end of the price range, while thicker sheets or higher-grade aluminum can be on the higher end. It is always recommended to compare prices from different suppliers to get the best deal.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- The utilization of aluminum sheets in the transportation sector offers numerous benefits. To begin with, aluminum, being a lightweight material, proves to be advantageous in vehicles by reducing fuel consumption and increasing overall efficiency. This attribute is particularly significant in industries like aviation and automotive, where weight reduction plays a crucial role in enhancing performance. Furthermore, aluminum exhibits exceptional resistance to corrosion, which is pivotal in the transportation field where vehicles are exposed to diverse environmental conditions such as rain, snow, and road salt. The implementation of aluminum sheets helps prolong the lifespan of vehicles and diminishes the maintenance costs linked to corrosion-related problems. Moreover, aluminum is highly recyclable, making it a more sustainable option when compared to other materials. The transportation industry is increasingly prioritizing sustainability, and the utilization of aluminum sheets aligns with these objectives. Recycling aluminum consumes significantly less energy than producing it from raw materials, leading to reduced carbon emissions and energy consumption. Additionally, aluminum offers excellent formability and versatility, enabling it to be easily shaped into various forms and sizes. This characteristic allows manufacturers to design structures that are lightweight yet robust. This design flexibility facilitates the production of more aerodynamic vehicles, thereby improving fuel efficiency. Lastly, aluminum sheets possess a high strength-to-weight ratio, meaning they provide the necessary strength while remaining lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. In conclusion, the utilization of aluminum sheets in the transportation industry provides advantages such as weight reduction, corrosion resistance, sustainability, formability, versatility, and a high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: This question asks for a list of various methods used to treat the surface of aluminum sheets to improve their properties or appearance.

- <p>There are several types of surface treatment for aluminum sheets, each serving different purposes. These include: Anodizing, which creates a protective oxide layer and enhances corrosion resistance; Chemical Conversion Coating, such as chromate conversion, to improve paint adhesion and corrosion resistance; Electrolytic Polishing, which provides a smooth, shiny surface; Powder Coating, an electrostatic process that applies a durable coating; Paint Coating, offering a wide range of colors and finishes; and Mechanical Polishing, which smooths the surface and improves reflectivity. Each treatment has its specific applications and benefits, depending on the desired outcome for the aluminum sheet.</p>

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- Simply put, aluminum plate is pure metal, aluminum plate is only the surface of metal (surface metal processing), and the middle is polyethylene plastic.In the same thickness and specifications, the aluminum plate is heavier than the aluminum-plastic plate, and the price is generally higher than that of the aluminum plate. 2.5mm aluminum plate to see, polyester or fluorocarbon, aluminum material, machining drawings, are often n flat at around 250, aluminum plate, aluminum depends on the thickness of the plastic type and so on normal inner wall 40 yuan a square, 100 yuan per square wall aluminum plate and aluminum plate installation is a kind of the aluminum is only good processing and molding to the site, and then to the site after the aluminum plate molding, aluminum plate manufacturer's website will generally some. There are also some details please consult the steel E station through

- Q: my grandpa gave me a family harloom, a 1971 Honda Trail 90, after it sat in a shed for a good 30 years. i have got most everything in tip top shape except for the polished aluminum has become lightly tarnished. and because i am a perfectionist

- I helped a friend restore an old Honda 160. We did a combination of the things mentioned. We painted the engine cases with a high temp aluminum paint. We did the side covers by wet sanding with 400-800-1000 and then finishing with Semichrome. Other misc bits we went with flat black (makes the polished aluminum pop). It wasn't exactly stock, but it looked great. It would take an expert to know the difference.

- Q: How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding usually overlays two pieces together and presses them, heating them to melting state through current, you can try multiple sheets.

- Q: This question asks for a list of various types of aluminum sheets that can be found in the market.

- <p>Aluminum sheets available on the market can be categorized based on their thickness, surface finish, and alloy composition. Some common types include: 1) Mill Finish Sheets, which have a natural aluminum finish; 2) Polished Aluminum Sheets, offering a shiny surface; 3) Anodized Aluminum Sheets, which are coated with a protective oxide layer; 4) Checkered Aluminum Sheets, with a slip-resistant pattern; 5) Painted or Coated Aluminum Sheets, with a variety of colors and finishes; 6) Embossed Aluminum Sheets, featuring decorative patterns; 7) Aluminum Foil, which is very thin; and 8) Aluminum Alloy Sheets, such as 6061, 6063, and 2024, each with specific properties for different applications. These types cater to various industries and applications, from construction to automotive and aerospace.</p>

Send your message to us

Perforated Aluminum Foil Sheets for Collapsible Aluminium Tubes Slug/Circles

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords