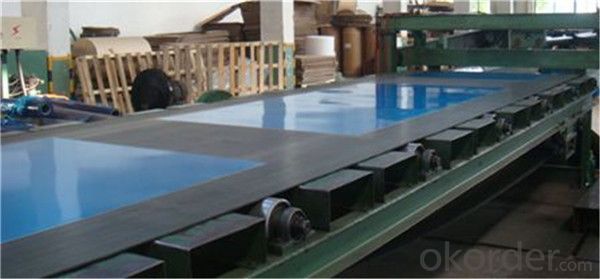

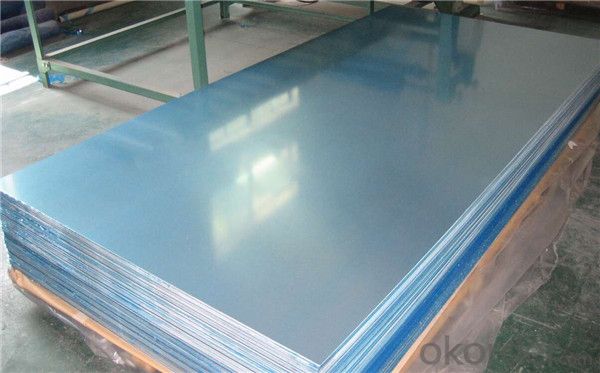

Perforated Rolls Aluminum Sheets / Aluminium Sheets / Aluminium Roll Product / Aluminium Flat Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

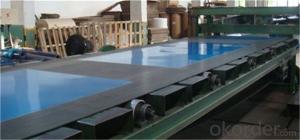

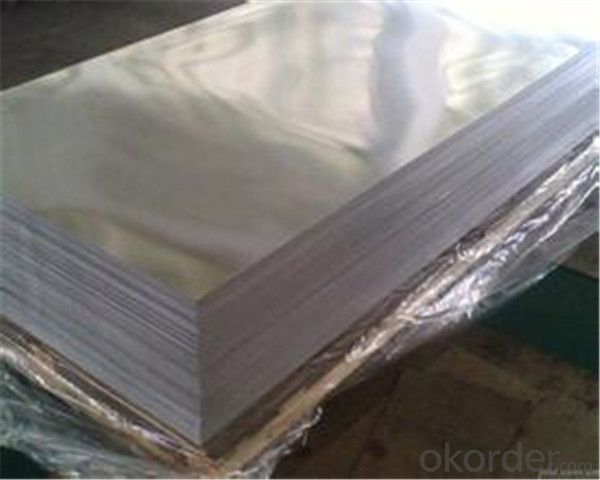

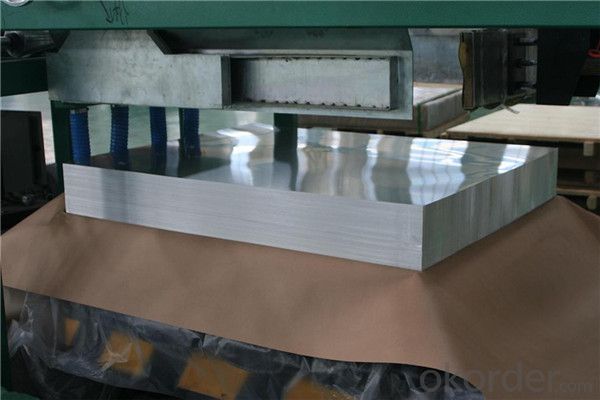

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: This question asks about the various types of aluminum sheets that are commonly used for roofing purposes, including their specific applications and characteristics.

- <p>Aluminum sheets used for roofing come in various types, each with unique properties and applications. The main types include: 1) Corrugated Aluminum Sheets: Known for their strength and durability, these are often used in commercial and industrial roofing due to their ability to withstand harsh weather conditions. 2) Standing Seam Aluminum Sheets: These provide a sleek, clean look and are favored for their water-resistant properties, making them ideal for residential and architectural applications. 3) Flat Aluminum Sheets: Offer a smooth surface finish and are used where a uniform appearance is desired. 4) Perforated Aluminum Sheets: These have small holes that allow for ventilation, reducing heat build-up and are used in areas requiring natural light and air circulation. 5) Embossed Aluminum Sheets: With a textured surface, they provide added rigidity and are used in both residential and commercial settings for their aesthetic appeal. Each type is chosen based on the specific needs of the roofing project, such as design, weather resistance, and longevity.</p>

- Q: What is an aluminium plate? What is the difference between carbon steel sheet, galvanized sheet and stainless steel plate?What is the order of the price? Thank you

- Aluminized sheet, the full name of aluminum plating, also known as aluminized steel plate, also known as hot dipped aluminum plate.Aluminized steel plate is an aluminum silicon alloy coating steel plate, in which the aluminum content is 90%, silicon 10%. The aluminized steel plate has good heat resistance, heat reflection and corrosion resistance. Its mechanical and physical properties are better than those of cold-rolled steel sheet. Because of the superior performance of aluminized steel sheet, it has been widely used in our daily necessities. Such as car muffler, household appliances and so on.

- Q: what’s the difference of activated aluminum and aluminum sheet?

- you can use weak acid ,weak base solvent or steam to clean the oil and dirt on the surface, it's activated aluminum, their difference is that activated aluminum has porous structure oxide film.

- Q: What is the tensile strength of aluminum sheets?

- The tensile strength of aluminum sheets can vary depending on the specific alloy and temper of the material. However, on average, aluminum sheets typically have a tensile strength ranging from 10,000 to 45,000 pounds per square inch (psi). It is important to note that different grades and thicknesses of aluminum sheets will have different tensile strength values. Additionally, factors such as heat treatment, processing, and alloy composition can also affect the tensile strength of aluminum sheets. Therefore, it is necessary to consult the manufacturer's specifications or perform specific tests to determine the precise tensile strength of a particular aluminum sheet.

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust due to their natural oxide coating that forms a protective barrier against corrosion.

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, including welding, riveting, adhesive bonding, and mechanical fastening. Welding involves melting and fusing the aluminum sheets together using heat, while riveting involves using metal fasteners to hold the sheets together. Adhesive bonding uses specialized adhesives to create a strong bond between the sheets, and mechanical fastening involves using screws, bolts, or other mechanical devices to secure the sheets together.

- Q: Are aluminum sheets suitable for food packaging?

- Yes, aluminum sheets are suitable for food packaging. Aluminum is a lightweight, non-toxic, and corrosion-resistant material that provides an effective barrier against moisture, oxygen, and light. It helps preserve the quality, taste, and freshness of food products, making it a popular choice for packaging perishable items. Additionally, aluminum is recyclable, making it an environmentally-friendly option for food packaging.

- Q: What are the different methods of joining aluminum sheet?

- Some of the different methods of joining aluminum sheet include welding, adhesive bonding, riveting, clinching, and mechanical fastening.

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Yes, aluminum sheets can be used for manufacturing aircraft parts. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry. It possesses excellent strength-to-weight ratio, corrosion resistance, and good formability, making it suitable for various aircraft applications. Aluminum sheets can be easily fabricated into complex shapes and are used to manufacture components such as wings, fuselages, panels, and structural supports in aircraft. Additionally, aluminum's high conductivity allows for efficient heat dissipation in critical areas of the aircraft. Overall, aluminum sheets are a preferred choice for manufacturing aircraft parts due to their favorable properties and reliability in the aerospace industry.

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Your 30-35 lb draw bow is slightly underpowered for hunting. Some states regulate the draw weight to around 50 lbs. So that your arrow does damage when it hits. I would recommend a compound bow as they are easier to draw and the power is there. tTe power will affect the arrow as they bend pretty good when released. But all arrows do that.even the glass and wooden arrows. If there is a flaw in the arrow throw it away!!

Send your message to us

Perforated Rolls Aluminum Sheets / Aluminium Sheets / Aluminium Roll Product / Aluminium Flat Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords