Adp Aluminum Coils - PE PVDF Marble Anodized Coat Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PE PVDF Marble Anodized Coat Aluminum Coil

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of PE PVDF Marble Anodized Coat Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PE PVDF Marble Anodized Coat Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

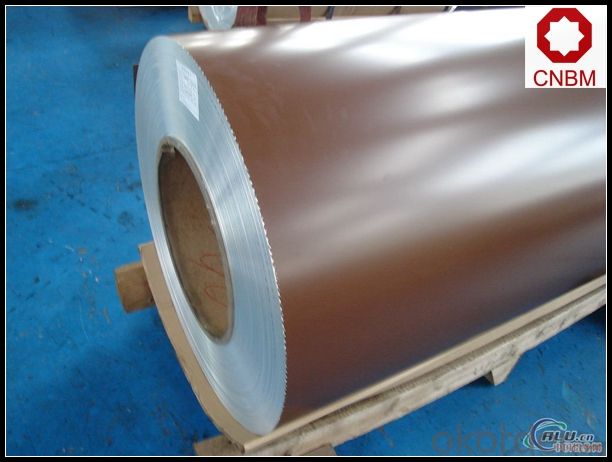

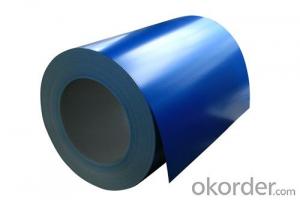

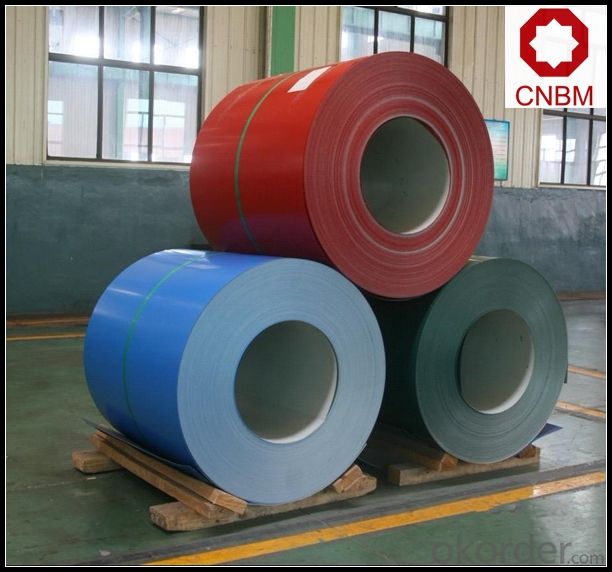

5. Image of PE PVDF Marble Anodized Coat Aluminum Coil

6. Package and shipping of PE PVDF Marble Anodized Coat Aluminum Coil

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any limitations to the minimum coil width of aluminum coils?

- Yes, there are limitations to the minimum coil width of aluminum coils. The minimum coil width is determined by various factors, including the manufacturing process and the equipment used. Generally, the coil width is limited by the capabilities of the rolling mill or other processing machinery. The minimum coil width is typically determined by the size of the rolls or mandrels used in the production process. If the coil width is too narrow, it may cause issues with the stability and integrity of the coil, making it more difficult to handle and transport. Additionally, a narrower coil width may also affect the overall efficiency of the manufacturing process. Therefore, it is important to consider these limitations when determining the minimum coil width for aluminum coils.

- Q: Can aluminum coils be used for signage purposes?

- Yes, aluminum coils can be used for signage purposes. Aluminum is a versatile and lightweight material that is commonly used in the signage industry. It has excellent corrosion resistance, making it suitable for both indoor and outdoor applications. Aluminum coils can be easily cut and formed into various shapes and sizes, allowing for customizable signage designs. Additionally, aluminum is highly durable and can withstand harsh weather conditions, making it a long-lasting option for signage. The coils can be painted or coated with different finishes to achieve the desired aesthetic appeal, while also providing protection against fading and scratching. Overall, aluminum coils are a popular choice for signage purposes due to their versatility, durability, and aesthetic appeal.

- Q: What are the width tolerances for aluminum coils?

- The width tolerances of aluminum coils can differ based on the specific application and industry standards. Generally, the typical range for standard width tolerances is between +/- 0.005 inches to +/- 0.020 inches. These tolerances guarantee that the width of the aluminum coil remains within an acceptable range and meets the necessary dimensions for the intended use. It is important to mention that tighter tolerances may be attainable depending on the manufacturing processes and equipment capabilities. Thus, consulting the appropriate industry standards and specifications is crucial in determining the precise width tolerances needed for a specific application.

- Q: Is the aluminum coil with damaged side still useful?

- The side of tire, also called side wall, is the thinnest and most fragile. Side wall damages can be divided into swell and scratch. The swell is often caused by external force (The car is trapped in pit or on curb when you are driving fast). It can cause the cord thread break so that the rubber of the tire side wall cannot be fixed and tightened. The size of the swell is often as big as that of an one-yuan coin and will become bigger as the traveling distance increases. Under such circumstance, it is recommended to replace the tire. Scratch is usually caused by bad roads or debris on the road. It is recommended to replace the tire if the scratch in the side wall is obvious and the cord thread break. If the front wheels have such damages, the tire should be replaced as soon as possible (Because the steering, braking and driving is mainly based on the front wheels.). If there is no spare tire on site, change the front damaged tire with the rear tire and drive to an appropriate place.

- Q: How do aluminum coils contribute to lightweight vehicle design?

- Due to their unique properties and manufacturing processes, aluminum coils play a crucial role in the attainment of lightweight vehicle designs. Aluminum, being a lightweight material itself and weighing only about one-third of steel, is an ideal choice for lightweight vehicle design. When aluminum is formed into coils, it offers various advantages that contribute to the overall reduction in vehicle weight. First and foremost, aluminum coils possess high formability, enabling the creation of complex shapes using less material. This characteristic allows automakers to design intricate body panels and structural components that are both lightweight and possess improved aerodynamics and fuel efficiency. The ability to shape aluminum coils intricately also provides increased flexibility in design, leading to more innovative and visually appealing vehicle designs. Secondly, aluminum coils exhibit an exceptional strength-to-weight ratio, making them an excellent option for structural components. Despite their lightweight nature, aluminum coils provide exceptional structural integrity, ensuring the safety and durability of the vehicle. By incorporating aluminum coils into the chassis, suspension systems, and other critical components, automakers can reduce weight while maintaining the necessary strength and rigidity required for safe operation. Moreover, aluminum coils possess excellent corrosion resistance, which is vital for the long-term longevity of the vehicle. Corrosion can significantly impact the structural integrity and overall performance of a vehicle. By utilizing aluminum coils, automakers can minimize the risk of corrosion-related issues, resulting in a longer lifespan for the vehicle and reduced maintenance costs. Lastly, the utilization of aluminum coils aids in the overall reduction of vehicle weight, leading to improved fuel efficiency and decreased greenhouse gas emissions. Lighter vehicles require less energy for acceleration and to maintain speed, resulting in enhanced fuel economy. This benefit becomes increasingly significant as the automotive industry strives to develop more sustainable and eco-friendly vehicles. In conclusion, aluminum coils make a significant contribution to the design of lightweight vehicles by offering high formability, exceptional strength-to-weight ratio, corrosion resistance, and overall weight reduction. These properties enable automakers to design vehicles that are not only lighter but also safer, more fuel-efficient, and visually appealing. As the demand for lightweight vehicles continues to rise, aluminum coils play a vital role in achieving these design objectives.

- Q: who invented aluminum and or aluminum foil?

- Well, God invented aluminum, as it is an ELEMENT. The other, I don't know.

- Q: How are aluminum coils transported and packaged?

- Aluminum coils are typically transported and packaged using wooden crates or pallets. The coils are securely strapped or bundled together to prevent movement during transit. They are then loaded onto trucks or shipping containers for transportation, ensuring they are well-protected to avoid any damage or deformation.

- Q: Aluminum roll, which companies are used?

- Too many things that you can see every day, with all the things that are made of aluminum, and the companies that make these aluminum products are useful, so it's unclear!

- Q: How do aluminum coils perform in extreme weather conditions?

- Aluminum coils perform well in extreme weather conditions due to their excellent resistance to corrosion and ability to withstand high temperatures. They can effectively dissipate heat and maintain their structural integrity, making them a reliable choice for various applications in extreme climates.

- Q: How are aluminum coils protected against moisture during storage?

- Aluminum coils are typically protected against moisture during storage through the use of various methods and materials. One common method is the application of a protective coating, such as a thin layer of oil or a corrosion-resistant film, which forms a barrier between the coil and any moisture present in the environment. This coating helps to prevent direct contact between the aluminum surface and water, minimizing the risk of corrosion or other moisture-related damage. In addition to protective coatings, aluminum coils may also be stored in a controlled environment with low humidity levels. This can be achieved by storing the coils in a dry warehouse or using dehumidifiers to remove excess moisture from the storage area. By controlling the humidity, the risk of moisture condensation on the coils is reduced, further protecting them from potential damage. Furthermore, proper packaging is crucial in protecting aluminum coils against moisture during storage. Coils are often wrapped in moisture-resistant materials, such as plastic or moisture-proof paper, to create a barrier that prevents moisture from reaching the coils. Additionally, the packaging is often sealed to provide an airtight environment, further minimizing the chances of moisture ingress. Regular inspection and maintenance are also important to ensure the continued protection of aluminum coils during storage. This includes checking the integrity of the protective coatings, monitoring the storage environment for any changes in humidity levels, and promptly addressing any signs of moisture damage. Overall, the use of protective coatings, controlled storage environments, proper packaging, and regular maintenance are key factors in protecting aluminum coils against moisture during storage. By implementing these measures, the risk of moisture-related damage is significantly reduced, ensuring the quality and integrity of the coils until they are ready for use.

Send your message to us

Adp Aluminum Coils - PE PVDF Marble Anodized Coat Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords