Wholesale Aluminum Coils - PE-PVDF Coated, Good Price, High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

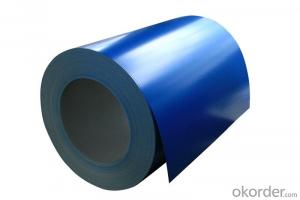

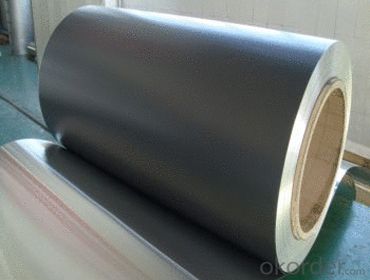

Structure of Aluminium Coated Coil Description:

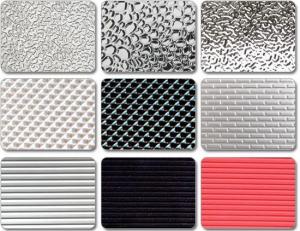

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

Advertisement: display platforms, signboards, fascia, shop fronts...

Main Features of the Aluminium Coated Coil:

Enviromental, light weight, waterproof, fireproof, anti-rust, weather resistance, easy cleaning, easy matching with other decoration materials...

Images of Aluminium Coated Coil:

Aluminium Coated Specifications:

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc. |

Thickness | 0.1~1.6mm |

Width | 21~1600mm |

Application | Decorative Materials |

Surface Treatment | Coated |

Temper | O - H112 |

Hardness | More than 2H |

Yield (≥ MPa) | 160 |

Temper | O - H112 |

Ultimate Strength (≥ MPa) | 175 |

Elongation (≥ %) | 6 |

Packing material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical( eye to sky) or horizontal( eye to wall) |

Standard spec | 1000mm xC, 1200mm xC etc |

Shipping | Container Loading or Bulk Pack |

FAQ of Aluminium Coated Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: What is the shear strength of aluminum coils?

- Various factors, such as alloy composition, temper, thickness, and processing conditions, can cause the shear strength of aluminum coils to vary. When compared to materials like steel or titanium, aluminum alloys generally have lower shear strength. However, the primary considerations for using aluminum coils are their lightweight nature, corrosion resistance, and malleability, rather than their shear strength. To obtain a more precise answer, it is necessary to specify the exact alloy, temper, and dimensions of the aluminum coil in question. These factors greatly impact the shear strength of the material. Additionally, it is important to note that factors like impurities, heat treatment, and the manufacturing process employed can influence shear strength. In conclusion, the shear strength of aluminum coils can differ based on various factors, and it is crucial to consider the specific alloy, temper, and dimensions to determine the exact strength of the material for a given application.

- Q: What unique considerations or precautions need to be taken when handling aluminum coils?

- <p>When handling aluminum coils, there are several special requirements to consider. First, it's crucial to handle the coils carefully to avoid denting or scratching the surface, which can affect their quality and value. Secondly, due to aluminum's lightweight and high strength, specialized equipment like slitters and rewinders may be necessary to process the coils. Additionally, it's important to store aluminum coils in a dry environment to prevent corrosion. Proper ventilation is also required to avoid condensation, which can lead to oxidation. Finally, safety measures such as wearing protective gear and following material handling guidelines are essential to prevent accidents and injuries.</p>

- Q: Are aluminum coils compatible with different joining methods?

- Different joining methods can be used with aluminum coils. Aluminum, a versatile metal, can be joined using techniques like welding, brazing, soldering, and mechanical fastening. The choice of method depends on the specific application and desired joint properties. To join aluminum coils, welding is commonly used as it creates a strong and durable bond. Various welding techniques, such as MIG, TIG, and resistance welding, can be employed based on the thickness and alloy type. Brazing is another effective method for joining aluminum coils. It involves heating a filler material with a lower melting point than the base metal to create a strong joint. Brazing is suitable when joining aluminum coils with dissimilar metals. For thin aluminum coils or when a lower temperature method is necessary, soldering is a suitable option. It involves melting a low-temperature alloy (solder) to join the coils together. Soldering finds common use in electronics and plumbing applications. Mechanical fastening methods like bolts, screws, rivets, or clips can also be used to join aluminum coils. These methods provide a reliable and removable joint, making them appropriate for applications requiring disassembly. In conclusion, different joining methods, including welding, brazing, soldering, and mechanical fastening, can be used with aluminum coils. The choice depends on factors like the application, alloy type, and desired joint properties.

- Q: could you please help me find information of the element aluminum??? all the information i can get will be great... thanks very mucho.... who discovered? where can i find pictures of it?

- hi ive found this: Aluminium is a silvery white member of the boron group of chemical elements. It has the symbol Al and its atomic number is 13. It is not soluble in water under normal circumstances. Aluminium is the most abundant metal in the Earth's crust, and the third most abundant element, after oxygen and silicon. It makes up about 8% by weight of the Earth's solid surface. Aluminium is too reactive chemically to occur in nature as a free metal. Instead, it is found combined in over 270 different minerals.[5] The chief source of aluminium is bauxite ore. Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are very important in other areas of transportation and building. Its reactive nature makes it useful as a catalyst or additive in chemical mixtures, including ammonium nitrate explosives, to enhance blast power. Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. Aluminium is nonmagnetic and nonsparking. It is also insoluble in alcohol, though it can be soluble in water in certain forms. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[6] Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

- Q: How are aluminum coils priced in the market?

- Aluminum coils are priced in the market based on several factors. The primary factor influencing the price of aluminum coils is the current market price of aluminum. Since aluminum is a commodity, its price is determined by global supply and demand dynamics, as well as factors like production costs and currency fluctuations. Additionally, the cost of processing and manufacturing aluminum coils also affects their pricing. This includes expenses such as refining, alloying, rolling, and any other specialized processes required to produce the coils. The cost of energy, labor, and raw materials used in the production process also contribute to the overall pricing. Furthermore, market competition and the overall demand for aluminum coils influence their pricing. If there is high demand for aluminum coils and limited supply, the prices are likely to be higher. Conversely, if there is low demand and excess supply, prices may be lower. The size, thickness, and quality of the aluminum coils also play a role in determining their price. Thicker, larger, and higher-quality coils generally command a higher price due to the increased material and processing costs involved. Finally, transportation costs, import/export duties, and taxes imposed by different countries can also impact the pricing of aluminum coils. These additional costs are often factored into the final price of the product. In summary, the pricing of aluminum coils in the market is influenced by the current market price of aluminum, production costs, market competition, demand and supply dynamics, size and quality of the coils, as well as additional costs associated with transportation and taxes.

- Q: Can aluminum coils be used in food processing or packaging?

- Yes, aluminum coils can be used in food processing or packaging. Aluminum is a preferred material for food-related applications due to its non-toxicity, corrosion resistance, and ability to maintain product freshness and quality. It is commonly used in food packaging, such as cans, foil, and trays, and is also utilized in food processing equipment like cookware and machinery.

- Q: How are aluminum coils used in the production of food processing equipment?

- Aluminum coils are commonly used in the production of food processing equipment due to their excellent thermal conductivity, corrosion resistance, and lightweight nature. These coils are often formed into various shapes and sizes to create components like heat exchangers, evaporators, and condensers that help regulate temperature during food processing. Additionally, aluminum coils can be easily cleaned and sanitized, making them ideal for use in the food industry where hygiene is crucial.

- Q: Is it possible to use aluminum coil for crafting decorative items?

- <p>Yes, you can use aluminum coil to make a decoration piece. Aluminum is a versatile material that is lightweight, durable, and easy to manipulate. It can be bent, twisted, or cut into various shapes to create unique decorative items. Common uses include making sculptures, wall art, and even jewelry. Due to its malleability and resistance to corrosion, aluminum coil is an excellent choice for decorative purposes, especially for outdoor decorations where weather resistance is important.</p>

- Q: Can aluminum coils be used in high-humidity environments?

- Indeed, high-humidity environments can accommodate the use of aluminum coils. Due to its corrosion-resistant nature, aluminum proves to be a fitting material for areas with elevated humidity levels. The formation of a natural oxide layer on the aluminum surface acts as a safeguard against moisture, effectively warding off rust and corrosion. Hence, aluminum coils are widely favored for HVAC systems, as they encounter regular exposure to moisture and humidity. Moreover, the lightweight, durable, and exceptional heat transfer properties of aluminum coils render them an optimum selection for a multitude of industrial and commercial applications in high-humidity settings.

Send your message to us

Wholesale Aluminum Coils - PE-PVDF Coated, Good Price, High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords