Customized Anodized Aluminum Coil - PE Solid and Metallic Color Coated Aluminium Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PE Solid and Metallic Color Coated Aluminium Coils with High Quality

PE solid and metallic color coated aluminium coils are with excellent acid-resistance and alkali-resistance. They have super characters in environment protection, flame-resistance, and groovy colors.

PE solid and metallic color coated aluminium coils are widely used for aluminum composite panels. We normally use alloy 3003 and temper H16.

We have different colors for aluminum composite panels. RAL numbers are no problem for us. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of PE Solid and Metallic Color Coated Aluminium Coils with High Quality

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

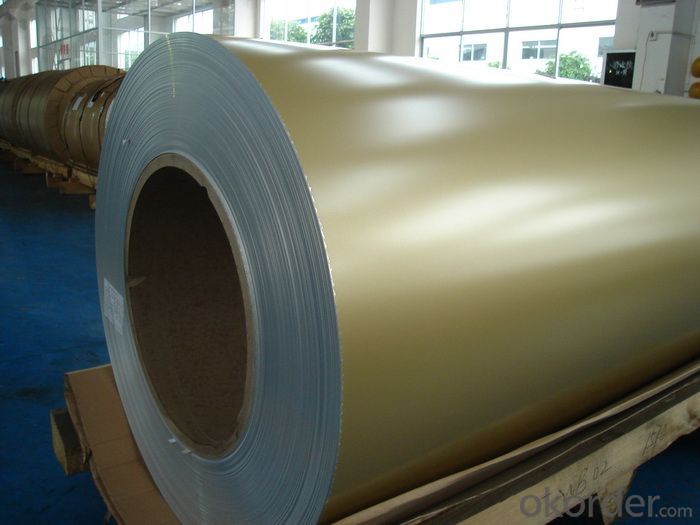

3. PE Solid and Metallic Color Coated Aluminium Coils with High Quality Images

4. Specification of PE Solid and Metallic Color Coated Aluminium Coils with High Quality

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are aluminum coils resistant to abrasion?

- Yes, aluminum coils are generally resistant to abrasion. Aluminum is known for its durability and ability to withstand wear and tear. It has a high strength-to-weight ratio and excellent corrosion resistance properties, making it suitable for various applications where abrasion resistance is required. Additionally, aluminum coils are often coated or treated with protective finishes, further enhancing their resistance to abrasion. However, the specific level of resistance may vary depending on the specific alloy and the surface treatment applied to the coils.

- Q: How should aluminum coil be stored to maintain its quality and prevent damage?

- <p>The best way to store aluminum coil involves several key practices: Store the coil in a clean, dry, and well-ventilated area to prevent moisture and dirt accumulation. Ensure the storage area is free from corrosive substances and temperature fluctuations. Use pallets or racks to keep coils off the ground, and avoid stacking heavy items on top. Protect coils with plastic covers or wrapping to prevent dust and scratches. Organize coils by size, type, and grade for easy access and to prevent damage during handling. Regularly inspect stored coils for signs of damage or corrosion and rotate stock to minimize prolonged storage of any single coil.</p>

- Q: Are there any limitations or restrictions on the use of aluminum coils?

- Yes, there are limitations and restrictions on the use of aluminum coils. Some of the limitations include the maximum operating temperature, which is typically lower compared to other metals, such as copper. Aluminum coils may also have lower electrical conductivity, making them unsuitable for certain applications that require high conductivity. Additionally, the corrosion resistance of aluminum coils can be compromised in certain environments, necessitating protective coatings or alternative materials. Lastly, the strength and durability of aluminum coils may be lower compared to other materials, which may limit their use in certain high-stress applications.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: Is it possible to use a grinder for cutting aluminum coil?

- <p>Yes, you can use a grinder to cut aluminum coil, but it's essential to choose the right type of grinder and blade. A metal cutting grinder with a suitable blade designed for cutting aluminum is recommended. Ensure the blade is sharp and the grinder is powerful enough to handle the material. Always wear appropriate safety gear, including gloves and eye protection, as cutting aluminum can produce sharp edges and flying debris. Be cautious of the heat generated during cutting, as it can warp or damage the aluminum.</p>

- Q: What are the potential health hazards associated with the use of old aluminum coils?

- <p>Using old aluminum coils can pose health risks due to potential leaching of aluminum into food or beverages. Long-term exposure to aluminum may lead to cognitive impairments and neurological issues. Additionally, old coils may have accumulated dirt, bacteria, or other contaminants that could cause infections or digestive problems. It's important to regularly inspect and replace aluminum cookware to ensure safety.</p>

- Q: This question seeks advice on methods to prevent rust formation on aluminum coils.

- <p>To prevent rust on aluminum coil, ensure proper storage conditions by keeping the coils dry and avoiding contact with moisture. Use protective coatings or sealants that are compatible with aluminum to create a barrier against the elements. Regularly inspect the coils for signs of corrosion and clean them with a non-abrasive cleaner to remove any contaminants. Avoid using harsh chemicals that could accelerate oxidation. Maintain good ventilation in storage areas to reduce humidity, which can contribute to rust formation. Finally, consider using anodizing or other surface treatments that enhance the aluminum's natural resistance to corrosion.</p>

- Q: Can a rolling machine be utilized to transform aluminum coils into flat sheets?

- <p>Yes, you can use a rolling machine to roll aluminum coils into sheets. Rolling machines are specifically designed to apply pressure and reduce the thickness of metal coils, such as aluminum, into thinner, flatter sheets. The process involves passing the aluminum coil through the rolling mill, where it is compressed between rollers. This process can be repeated to achieve the desired thickness and flatness of the aluminum sheet. It's important to ensure the rolling machine is suitable for aluminum and that the appropriate settings are used to avoid damaging the material or the machine.</p>

- Q: What are the different color options for coated aluminum coils?

- Coated aluminum coils are available in a wide range of color options to suit various aesthetic preferences and project requirements. Some of the common color options for coated aluminum coils include white, black, silver, gray, bronze, gold, red, blue, green, and brown. These colors can be achieved through different coating processes and techniques, such as powder coating, PVDF coating, or polyester coating. Additionally, custom color options are also available, allowing customers to choose a specific color that matches their design vision or brand identity. The color options for coated aluminum coils provide versatility and flexibility, enabling them to be used in various applications, including building facades, roofing systems, signage, interior decoration, and more.

- Q: How do aluminum coils perform in high humidity environments?

- Aluminum coils perform well in high humidity environments due to their inherent resistance to corrosion. Unlike many other metals, such as iron or steel, aluminum does not rust when exposed to moisture. This makes it a suitable choice for applications where high humidity is a concern, such as air conditioning systems or refrigeration units. The corrosion resistance of aluminum is primarily due to the formation of a thin layer of aluminum oxide on its surface when exposed to oxygen. This oxide layer acts as a protective barrier against further oxidation, preventing the metal from deteriorating even in humid conditions. Moreover, the lightweight nature of aluminum allows for better heat transfer and energy efficiency in cooling systems. This property makes aluminum coils a popular choice as heat exchangers, as they can effectively transfer heat from the air or fluid passing through them. Additionally, aluminum coils are typically coated with a protective layer or treated with a corrosion-resistant coating to further enhance their performance in high humidity environments. These coatings provide an extra layer of protection against moisture and other corrosive elements, ensuring the longevity and reliability of the coils. In summary, aluminum coils are highly suitable for high humidity environments due to their resistance to corrosion and their efficient heat transfer properties. The combination of these factors makes them a reliable choice for various applications where moisture is a concern.

Send your message to us

Customized Anodized Aluminum Coil - PE Solid and Metallic Color Coated Aluminium Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords