Aluminum Sheet Coils - Coating Guarantee PE PVDF Aluminum Coated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Coating Guarantee PE PVDF Aluminum Coated Sheet

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Coating Guarantee PE PVDF Aluminum Coated Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Coating Guarantee PE PVDF Aluminum Coated Sheet

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

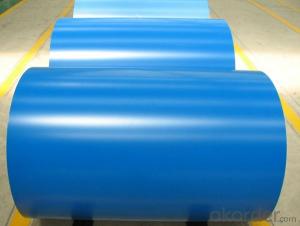

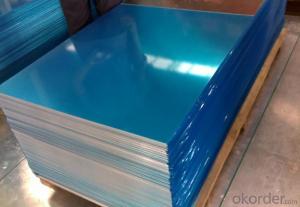

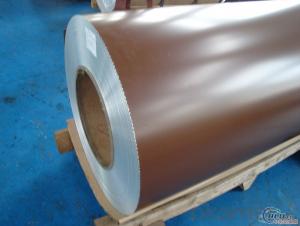

5. Image of Coating Guarantee PE PVDF Aluminum Coated Sheet

6. Package and shipping of Coating Guarantee PE PVDF Aluminum Coated Sheet

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in the production of window frames?

- Yes, aluminum coils can be used in the production of window frames. Aluminum is a lightweight and durable material that is commonly used in the construction industry due to its corrosion resistance and strength. Aluminum coils can be easily formed into various shapes, including window frames, making them an ideal choice for window manufacturing. Additionally, aluminum is a sustainable material that can be easily recycled, making it an environmentally friendly option for window frame production.

- Q: Well, we've got the existing old school 7 layers of peeling yucky painted siding and we're trying to weigh our options. So here's my questions:1) Is it cost effective to replace Aluminum with Vinyl?2) Is Vinyl truly as costly as we keep hearing? **Home is small 1,100 sq.ft with a 2.5 car Garage**3) Is painting this existing siding a wise choice since the current paint job on it looks terrible? We just need to make it more a home, right now it's gorgeously all new and redone inside and on the outside it still resembles the day we bought it in forclosure. Aside from my green grass I busted my butt on last summer.Please advise.

- Aluminum Siding Vs Vinyl Siding

- Q: What are aluminum coils used for and what are their applications?

- <p>Aluminum coils are versatile metal products that serve various purposes. They are primarily used in construction, manufacturing, and packaging industries. Some common applications include roofing and siding materials, heat exchangers, food and beverage cans, automotive parts, and electrical components. Aluminum coils are valued for their lightweight, corrosion resistance, and high thermal and electrical conductivity, making them ideal for a wide range of applications where durability and efficiency are required.</p>

- Q: How do aluminum coils perform under high-temperature applications?

- Aluminum coils perform well under high-temperature applications due to their high thermal conductivity and excellent heat dissipation properties. They can effectively withstand elevated temperatures without deforming or losing their structural integrity. Moreover, the corrosion resistance of aluminum makes it a suitable choice for applications where high temperatures and potential exposure to harsh environments are involved.

- Q: Are aluminum coils suitable for electrical insulation?

- Aluminum coils, unfortunately, do not possess the right qualities for electrical insulation. As a result of its conductivity, aluminum facilitates the passage of electric current rather than impeding it. When it comes to electrical systems, the presence of insulation becomes indispensable in order to impede the flow of electricity and provide protection against short circuits or electrical shocks. To achieve this, materials like rubber, plastic, or ceramic are commonly employed due to their remarkable resistance to electric current.

- Q: How are aluminum coils used in signage and advertising?

- Signage and advertising frequently utilize aluminum coils due to their versatility, durability, and cost-effectiveness. These coils are commonly employed in the creation of sign panels, which can be found in various locations such as billboards, retail stores, airports, and public spaces. One of the primary benefits of using aluminum coils in signage is their lightweight nature. This facilitates easier installation and transportation, making it the preferred choice for large-scale outdoor advertisements like billboards. Moreover, aluminum coils can be easily shaped and molded into various forms, enabling the creation of creative and attention-grabbing designs. Thanks to their durability, aluminum coils exhibit high resistance to weather conditions, including harsh sunlight, rain, and snow. This makes them exceptionally suitable for outdoor signage that needs to withstand the elements. The material's resistance to corrosion also ensures that the signage maintains its appearance over time, extending its lifespan and reducing maintenance costs. Additionally, aluminum coils can be coated or painted with different finishes, allowing for customization and branding. These finishes can range from vibrant colors to reflective or brushed effects, enhancing the visual impact of the signage. The smooth surface of aluminum coils also provides an excellent base for printing graphics and logos, resulting in high-quality and vibrant imagery. In terms of cost-effectiveness, aluminum coils are relatively affordable in comparison to other materials commonly used in signage, such as steel or plastic. The lightweight nature of aluminum also reduces shipping costs and simplifies installation, saving time and money for businesses or advertisers. Overall, aluminum coils play a critical role in the signage and advertising industry by providing a versatile, durable, and cost-effective solution for creating visually appealing and long-lasting signs. Their lightweight nature, resistance to weather conditions, customizable finishes, and affordability make them a popular choice for a wide range of signage applications.

- Q: I need to write as many interesting facts as i can about aluminum for a thing for school, any help?

- it is a lighter metal . you can prepare many alloys with it

- Q: Are aluminum coils suitable for decorative purposes?

- Aluminum coils are indeed appropriate for decorative purposes. Aluminum possesses versatility as a material, enabling it to be effortlessly shaped into different sizes and forms, which renders it suitable for decorative applications. Its lightweight characteristic, endurance, and resistance to corrosion make it an optimal selection for both interior and exterior decorative projects. Moreover, aluminum can undergo various finishes and coatings, such as powder coating or anodizing, to enhance its visual allure. These coatings present a wide array of colors, textures, and patterns, thereby facilitating boundless design possibilities. Furthermore, aluminum coils can be effortlessly manipulated into intricate designs, qualifying them for decorative elements like trims, accents, panels, or even sculptures. In summary, aluminum coils provide a cost-effective, long-lasting, and visually pleasing alternative for diverse decorative purposes.

- Q: What are the different coil winding methods for aluminum coils?

- Aluminum coils can be wound using various methods, each offering unique advantages and suitability for specific applications. Let's explore these methods: 1. Layer winding: By winding the aluminum wire in a single layer around the coil mandrel, this method proves useful in low voltage scenarios. It excels at thermal conductivity and heat dissipation. 2. Random winding: Without adhering to any specific pattern, the aluminum wire is randomly wound around the coil mandrel. This method is preferred for high voltage applications as it minimizes the risk of corona discharge and enhances insulation. 3. Concentric winding: As implied by its name, concentric winding involves winding the aluminum wire in concentric circles around the coil mandrel. It is ideal for space-restricted applications, enabling a high number of turns in a compact coil. 4. Interleaved winding: This method entails winding multiple layers of aluminum wire in an interleaved pattern. It reduces the overall size of the coil while maintaining a high number of turns and increasing inductance. 5. Helical winding: Here, the aluminum wire is wound in a helix pattern, either with a constant or varying pitch. Helical winding is commonly employed in applications requiring high inductance, such as inductors and transformers. 6. Sectional winding: In this method, the coil is divided into multiple sections, with each section being wound separately. It is commonly used in large-scale applications, making coil handling and installation easier. Each of these coil winding methods possesses its own strengths and considerations. The choice of method depends on specific application requirements, space limitations, and desired electrical characteristics.

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

Send your message to us

Aluminum Sheet Coils - Coating Guarantee PE PVDF Aluminum Coated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords