5005 Aluminum Coil with PE Coating for Aluminum Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels

Our Quality for PE coated aluminum coils with alloy 3003 is very good, especially in corrosion resistance, weather resistance and high strength.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

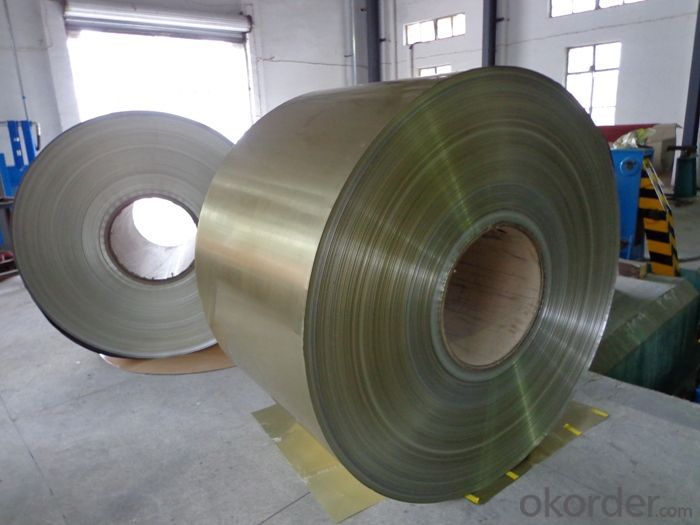

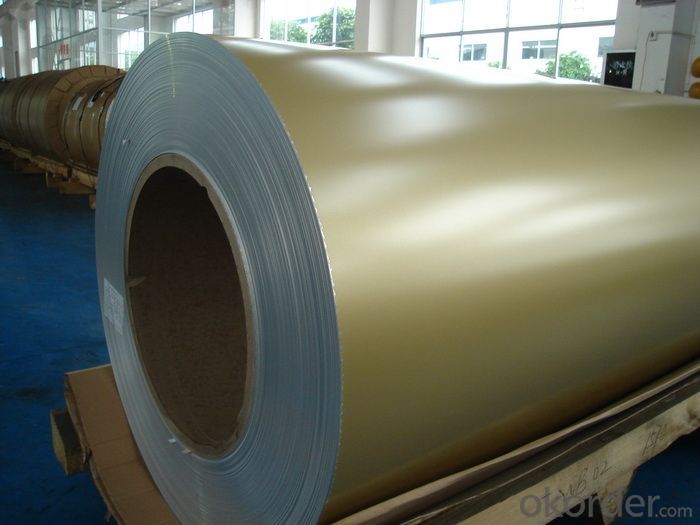

3. 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels Images

4. Specification of 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How do aluminum coils contribute to improved indoor comfort?

- Aluminum coils play a crucial role in improving indoor comfort through their contribution to the functioning of HVAC (heating, ventilation, and air conditioning) systems. These coils are commonly used in air conditioning units and heat pumps to facilitate the heat transfer process. The primary function of aluminum coils is to absorb heat from the indoor air and release it outside. When warm air passes over the coils, the aluminum absorbs the heat, causing the refrigerant inside the coils to evaporate. This evaporation process cools down the air, which is then circulated back into the room, resulting in a more comfortable indoor environment. The use of aluminum for coil construction is advantageous due to its excellent thermal conductivity properties. Aluminum is highly efficient in transferring heat, enabling the coils to rapidly absorb and release thermal energy. This efficiency allows the HVAC system to cool down the indoor air more effectively and quickly, contributing to improved comfort levels. Furthermore, aluminum coils offer numerous benefits over other coil materials, such as copper. Aluminum is lightweight, making it easier for the HVAC system to operate efficiently. It is also corrosion-resistant, ensuring the longevity and durability of the coils. This resistance to corrosion prevents the formation of contaminants or blockages that could hinder the heat transfer process, ultimately maintaining optimal indoor comfort. In summary, aluminum coils contribute to improved indoor comfort by facilitating efficient heat transfer in HVAC systems. Their ability to absorb and release thermal energy quickly, combined with their lightweight and corrosion-resistant properties, ensures a more effective cooling process, resulting in a comfortable indoor environment for occupants.

- Q: They say aluminum can be found in deodorants.And this aluminum is absorbed by the skin and block pores.Does the amount of aluminum affect the rate of how it dries up?

- Al does not have the ability to retain heat for very long. Therefore theroretically, the greater the amount of Al the faster the substance would dry.

- Q: The question asks if magnetic induction can be used to inspect the quality of an aluminum coil.

- <p>No, you cannot use magnetic induction to inspect the quality of an aluminum coil. Magnetic induction is a method used to detect flaws or discontinuities in ferromagnetic materials, such as steel, by inducing eddy currents. Aluminum is not a ferromagnetic material, so it does not retain magnetism or support the formation of eddy currents in the same way. Instead, other non-destructive testing methods like ultrasonic testing or radiographic testing may be more appropriate for inspecting the quality of aluminum coils.</p>

- Q: What are the different coil slitting methods used for aluminum coils?

- There are several coil slitting methods used for aluminum coils, including rotary shear slitting, loop slitting, and simultaneous multi-blanking. These methods involve different techniques and equipment to precisely cut and separate aluminum coils into narrower strips or sheets. Each method has its advantages and is chosen based on factors like coil thickness, width, and desired output.

- Q: Is it okay to combine copper with aluminum in case of minting or coin making? Thanks :)

- Well, there are aluminum alloys that have copper in them (although they usually have other metals also), so I don't think it would be a problem. If you're thinking of copper plated aluminum, there is the potential for a galvanic reaction (meaning like a battery cell) that could cause the coin to corrode and fall apart. It's the same problem with the current production of US cents (which are copper coated zinc).

- Q: How are aluminum coils used in the production of industrial machinery?

- Aluminum coils are widely used in the production of industrial machinery due to their unique properties and benefits. These coils are typically made from high-quality aluminum alloy, which offers excellent strength, durability, and corrosion resistance. One common application of aluminum coils in industrial machinery is in the manufacturing of heat exchangers. Heat exchangers play a crucial role in various industrial processes, including refrigeration, HVAC systems, and power generation. Aluminum coils are ideal for heat exchangers due to their high thermal conductivity, allowing for efficient heat transfer. Furthermore, aluminum coils are also utilized in the production of industrial equipment such as air compressors, pumps, and turbines. The lightweight nature of aluminum makes it an excellent choice for these applications, as it helps reduce the overall weight of the machinery. This, in turn, leads to improved energy efficiency and lower operational costs. Another significant advantage of aluminum coils is their malleability and formability. Aluminum is highly ductile, meaning it can be easily shaped and formed into various complex geometries required for the machinery's components. This allows manufacturers to create intricate parts and structures, ensuring precise fit and optimum performance. Additionally, aluminum coils offer exceptional resistance to corrosion, making them suitable for machinery used in harsh environments or exposed to corrosive materials. This corrosion resistance helps extend the lifespan of the machinery and reduces the need for frequent maintenance or replacement of parts. In summary, aluminum coils are essential components in the production of industrial machinery. They provide strength, durability, lightweight, and corrosion resistance, making them ideal for various applications such as heat exchangers, air compressors, pumps, and turbines. Their malleability also allows for intricate part fabrication, ensuring precise fit and optimal performance.

- Q: Can aluminum coils be used in heat exchanger fins?

- Yes, aluminum coils can be used in heat exchanger fins. Aluminum is a common material choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. Aluminum coils can efficiently transfer heat and withstand high temperatures, making them suitable for use in heat exchanger fins.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry due to its high strength-to-weight ratio. Its corrosion-resistant properties also make it an ideal choice for fuel tanks, as it can withstand the harsh conditions and chemicals found in aviation fuel. The use of aluminum coils allows for efficient manufacturing processes, as they can be easily formed and welded into the desired tank shape. Additionally, aluminum has excellent thermal conductivity, which helps dissipate heat generated during flight and prevents the fuel from overheating. Overall, aluminum coils are a suitable and widely-used material in the production of aircraft fuel tanks.

- Q: How are aluminum coils used in the construction industry?

- Aluminum coils are widely used in the construction industry due to their numerous beneficial properties. These coils are primarily employed in the fabrication of various building components, such as roofs, facades, gutters, and cladding systems. One of the main advantages of using aluminum coils in construction is their lightweight nature. Aluminum is significantly lighter than other commonly used metals like steel, making it easier to handle and install. This lightweight property also reduces the load on the building structure, allowing for more flexibility in design and minimizing the overall construction costs. Furthermore, aluminum coils offer exceptional corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface, which prevents it from rusting or deteriorating when exposed to moisture or harsh environmental conditions. This corrosion resistance ensures the longevity and durability of the building components, reducing maintenance and replacement costs in the long run. Aluminum coils are also highly malleable and can be easily formed into various shapes and sizes. This versatility allows architects and engineers to create innovative and aesthetically pleasing designs. Aluminum coils can be bent, folded, or molded to fit any architectural requirement, enabling the construction of unique and visually appealing structures. In addition, aluminum is an excellent conductor of heat and electricity. This property makes aluminum coils ideal for applications that require efficient thermal or electrical conductivity. For example, aluminum coils are often used in HVAC systems to transfer heat or in electrical wiring to ensure optimal performance. Moreover, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, making it a perfect choice for sustainable construction practices. The recyclability of aluminum coils reduces waste generation and conserves natural resources, contributing to a greener and more sustainable construction industry. In conclusion, aluminum coils are extensively used in the construction industry due to their lightweight nature, corrosion resistance, malleability, efficient conductivity, and sustainability. These coils facilitate the construction of durable, aesthetically pleasing, and energy-efficient buildings while reducing costs and environmental impact.

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a popular material choice for food storage containers due to its various advantageous properties. Firstly, aluminum is lightweight, making it easy to handle and transport. Additionally, aluminum has excellent thermal conductivity, which means it can cool down or heat up quickly, making it ideal for both hot and cold food storage. Moreover, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain intact. Furthermore, aluminum is a sustainable and recyclable material, making it environmentally friendly. However, it is important to note that aluminum containers should be lined with a food-grade coating to prevent any potential reaction between the metal and the food, especially acidic foods. Overall, aluminum coils are a suitable choice for food storage containers due to their lightweight nature, thermal conductivity, corrosion resistance, and recyclability.

Send your message to us

5005 Aluminum Coil with PE Coating for Aluminum Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords