Aluminum Coils Price - PE/PVDF Painted Aluminum Coil for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of PE/PVDF Painted Aluminum Coil for Construction

| Alloy No. | Thickness (mm) | Width (mm) | Temper | |

| A1050,A1060, A1070,A1100,A1235,A1245 | 0.2-3.0 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-2200 | H111,H112 | ||

| A3003,A3004,A3105 | 0.2-4.0 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-2200 | H111,H112 | ||

| A5052,A5083,A5754,A5005 | 0.2-4.0 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-2200 | H111,H112 | ||

| A6061,A6082,A6063 | 0.8-3.0 | 20-2200 | O | |

| A8011,A1145,A1235 | 0.005-0.2 | 20-2200 | O,,H18,H24 | |

| ID | 76mm,152mm,200mm,300mm,505mm | |||

| Packing : Export wooden pallets, wooden case | ||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006 | ||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | ||||

2. Application of PE/PVDF Painted Aluminum Coil for Construction

Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect

3. Feature of PE/PVDF Painted Aluminum Coil for Construction

1.High temperature resistant

2.Weathering resistant

3.Scrubbing resistant

4.Sound insulation

5.Acid or alkali proof

6. Fireproof

7.Light weight material is easy to construct and install

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

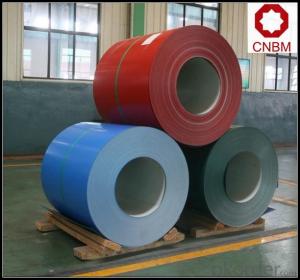

5. Image of PE/PVDF Painted Aluminum Coil for Construction

5. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for architectural façade systems?

- Indeed, architectural façade systems can indeed make use of aluminum coils. Aluminum is a remarkably adaptable and enduring material; it can be easily molded and manipulated to suit the specific design requirements of a building's façade. It possesses a lightweight structure, is resistant to corrosion, and can endure extreme weather conditions, rendering it an optimal choice for long-lasting exterior applications. Moreover, aluminum coils can be coated with a variety of finishes, such as paint or anodizing, to heighten their aesthetic appeal and provide additional protection against fading or chipping. The pliability and versatility of aluminum coils make them an exceptional choice for architectural façade systems, enabling the creation of imaginative and distinctive designs while maintaining durability and performance.

- Q: Can aluminum coils be painted or coated after installation?

- Yes, aluminum coils can be painted or coated after installation. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance or provide additional protection. Painting or coating aluminum coils after installation can help prevent corrosion, improve durability, and provide a customized finish. The type of paint or coating used will depend on the specific requirements and desired outcome. It is important to ensure that the aluminum surface is properly cleaned and prepared before applying any paint or coating to ensure adhesion and longevity.

- Q: I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- Use Aluminum gutters with the leaf guard drip edge system. You can get them in a seamless design from a pro contractor (check Licenses ). You will not have to clean them. Plastic gutters ot leaf guards deteriorate (dry rot) and become brittle.

- Q: How are aluminum coils protected against mechanical damage?

- Aluminum coils are protected against mechanical damage through various methods such as applying protective coatings, using durable outer casings, employing edge guards, and ensuring proper handling during transportation and installation.

- Q: What are the typical mechanical properties of aluminum coils?

- The mechanical properties of aluminum coils can vary depending on the specific alloy and temper of the material. However, some typical mechanical properties of aluminum coils include: 1. Tensile strength: Aluminum coils generally have a high tensile strength, which refers to the maximum amount of tensile stress a material can withstand before it breaks. This property is important for applications that require the material to withstand heavy loads or stress. 2. Yield strength: Yield strength is the amount of stress a material can withstand without permanently deforming. Aluminum coils typically have a relatively high yield strength, allowing them to maintain their shape and structural integrity under normal operating conditions. 3. Elongation: Elongation refers to the amount a material can stretch or deform before it fractures. Aluminum coils typically have a relatively high elongation, making them suitable for applications that require the material to be formed or bent without breaking. 4. Hardness: The hardness of aluminum coils can vary depending on the alloy and temper. Aluminum alloys can be heat-treated to increase their hardness, making them more suitable for applications that require wear resistance or need to withstand harsh environments. 5. Fatigue strength: Fatigue strength is the ability of a material to resist the formation and growth of cracks under cyclic loading conditions. Aluminum coils generally exhibit good fatigue strength, making them suitable for applications subjected to repeated or fluctuating loads. It is important to note that these properties can vary depending on the specific alloy, temper, and processing conditions of the aluminum coils. Therefore, it is recommended to consult the material specifications or contact the manufacturer for more accurate and detailed information on the mechanical properties of specific aluminum coils.

- Q: I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- No way!! because of the fact inspite of the bat, the helmet and the shin guards the undergo is plenty larger than a human and is going to basically get mad from the bat and kill you. Nope $800,000 isn't something for that!

- Q: What does 1060 of the 1060 Aluminum rolls stand for?

- Purity can reach more than 99%. Because it does not contain other technical elements, the production process is relatively simple, and the price is relatively cheap. It is the most commonly used series in the conventional industries.

- Q: Can aluminum coils be used for seamless gutters?

- Yes, aluminum coils can be used for seamless gutters. Aluminum is a popular choice for seamless gutter installations due to its durability, lightweight nature, and resistance to corrosion. The coils can be easily shaped and formed to create a seamless gutter system that effectively directs rainwater away from the building.

- Q: I had a physics exams today and it was asking whether or not a shiny surface aluminium blanket was suitable to keep the sleeper warm. I put that because it's a conductor of electricitiy, heat loss will be greater so it wont be suitable for keeping him warm. On the other hand, some other people said that because it had a shiny surface, thus a good reflector of heat, it would be suitable for keeping him warm. Are both arguments correct?

- Metals are reflective for the comparable reason that they habit electrical energy. The steel has an excellent number of electrons that are very loosely guaranteed to the atoms; they are in a position to leap from one atom to a distinctive very quite. that's virtually like a sea of electrons. Electrons soak up photons of sunshine then re-emit them in random instructions, that's stated as scattering. you are able to think of that if the electrons emit the photons in random instructions then the floor could be boring white, no longer vivid, yet in reality so long as a results of fact the floor irregularities on the steel are smaller than a wavelength of sunshine each and all of the photons entering into extraordinary instructions cancel one yet another out, in simple terms leaving those that leap off on the comparable attitude they arrived at - mirrored photograph in different words. Metals are literally sparkling. you are able to locate that frustrating to have self belief yet once you're finding at an liquid crystal reveal reveal screen you're finding by using a layer of steel now - it varieties electric powered circuits on the returned of the glass reveal. Any cloth that reflects easy additionally transmits it. while the electrons are greater efficient at interacting with the photons of sunshine the fabric is greater reflective, as in a steel; while fewer electrons are interacting with the easy the fabric is greater transmissive, like glass or water. yet observe that cup and water the two mirror easy besides as transmit it.

- Q: This is not for around the house. It is for my lab. I am pretty sure these one wires are Aluminum, but I need the connector they were made with and the power cable is copper. Would it be okay to still try to join the two.

- They can be joined but only through a suitable device marked specifically for aluminum to copper connections. See website below.

Send your message to us

Aluminum Coils Price - PE/PVDF Painted Aluminum Coil for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords