Painted Aluminum Sheets Canada - Aluminum Sheet 5052/5083 for Warships & Boats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheet 5052/5083 for Warships,Boat:

Mill Finished Aluminum Coil is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Mill finished aluminum coil for is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of the Aluminum Sheet 5052/5083 for Warships,Boat :

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

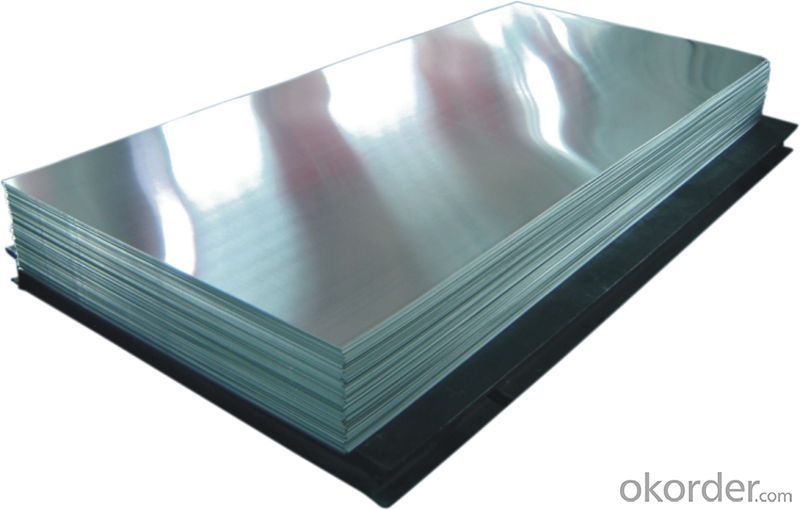

3. Aluminum Sheet 5052/5083 for Warships,Boat

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-100mm |

Width: | 30mm-1700mm |

4. Production of Aluminum Sheet 5052/5083 for Warships,Boat

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- Cryogenic applications are not suitable for 101 aluminum sheets. Although aluminum is generally a good choice for low-temperature environments because of its low thermal conductivity and high strength-to-weight ratio, 101 aluminum is not specifically designed to endure the extreme temperatures associated with cryogenic applications. In cryogenic applications, materials like aluminum alloys (for example, 5083 or 6061) or specialized cryogenic alloys like stainless steel or titanium are commonly used. These materials possess improved properties that allow them to handle the extreme cold temperatures without compromising their structural integrity. Therefore, it is advisable to use materials specifically designed for cryogenic applications to ensure optimal performance and safety.

- Q: A sample of aluminum and a sample of steel have superficially identical microstructures. Which would you expect to be stronger, and why?

- as far as i know we have an alloy named dur alumin cosists of Al, alloying element especially Mg it is as strong as steel .

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Polishing aluminum sheets involves smoothing the surface and creating a reflective finish using abrasive materials or polishing compounds.

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- Stainless steel plate and aluminum plate usually use acrylic structure glue.Acrylic structural adhesive two-component acrylate modified by synthesis and curing agent structural adhesive composition, A, B two agents are 100% solid components; fast curing, high strength, about 5 minutes to 30 minutes after the initial fixation strength up to 80%, 24 hours after the maximum strength; excellent resistance to acid and alkali, water, oil medium, high temperature resistance, better aging properties of metal items between strong adhesion, resistance strength is better than that of epoxy resin, excellent resistance to thermal shock, working at -30~150 DEG C; compliance with international environmental standards, has passed the European ROSH standard.

- Q: who knows the ceiling technology of aluminum sheet?

- Construction technology of ceiling aluminum sheet: (1) firstly check keel’s quality, the straight shape and uniformly forced state of boom, control the keel’s gap within 500mm, reduce the gap according to design requirement under humid environment. The lower surface of keel is smooth without a sense of bearing down, main device is closely connected with accessories, it can be bound after being confirmed qualified.(2) we should break the board along the cutting line and ensure the margin of cutting board straight and square without any chipping or arris defect. (3) while placing and fixing the board, we can place edge of aluminum-plastic panel(encapsulated edge) in the vertical direction of supporting keel, there is a phenomena of hanging. Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. You can start from a plate angle or middle position, and don’t place them at the same time. Slab joint should be straight and in the same width, without break joint. (4) in the process of joint, Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. And the butt joint should be stagger, the butt joint can’t be connected on the same keel. When you use doubling plate, the joints of the second layer board and the first layer board can’t be connected with the same keel, double-deck gypsum board should be staggered joints.

- Q: What are the safety standards for aluminum sheets utilized in construction?

- <p>Yes, there are safety standards for aluminum sheets used in construction. These standards ensure the material's quality, strength, and suitability for various applications. They include specifications for thickness, alloy type, and surface treatment. International standards such as ASTM B209 (for aluminum sheet and plate) and EN 485 (for aluminum and aluminum alloy sheets) govern the production and use of aluminum sheets in construction. Compliance with these standards is crucial for safety, durability, and to meet regulatory requirements in different regions.</p>

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: What are the different types of aluminum sheets available?

- There are several different types of aluminum sheets available, including plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, and painted aluminum sheets. Each type has its own unique attributes and applications.

- Q: What are the different alloys used in aluminum sheets?

- Aluminum sheets utilize a variety of alloys, each possessing its own distinct properties and characteristics. Some commonly employed alloys include: 1. Alloy 1100: Renowned for its exceptional corrosion resistance and superior electrical conductivity, this alloy finds extensive utilization in applications necessitating high formability and weldability. Examples include food packaging and electrical conductors. 2. Alloy 3003: Esteemed for its formidable formability, moderate strength, and outstanding corrosion resistance, this alloy enjoys widespread application in cooking utensils, chemical equipment, and general sheet metal work. 3. Alloy 5052: Recognized for its robust strength and commendable corrosion resistance, this alloy frequently finds application in marine settings, as well as aircraft fuel tanks and automotive components. 4. Alloy 6061: One of the most versatile and frequently employed aluminum alloys, this variant boasts excellent corrosion resistance, satisfactory weldability, and moderate strength. It is commonly utilized in structural components like frames and railings, as well as automotive and aerospace applications. 5. Alloy 7075: Distinguished by its impressive strength-to-weight ratio and exceptional fatigue resistance, this alloy is often chosen for applications necessitating formidable strength, such as aircraft and aerospace components, as well as high-performance sporting goods. These examples merely scratch the surface of the numerous alloys employed in aluminum sheets. The selection of a particular alloy hinges on the specific requirements of the application, encompassing factors such as strength, corrosion resistance, formability, and weldability.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum is a good choice for insulation jackets as it is lightweight, durable, and has excellent thermal conductivity. It can effectively reflect heat and prevent heat transfer, making it an efficient material for insulation purposes.

Send your message to us

Painted Aluminum Sheets Canada - Aluminum Sheet 5052/5083 for Warships & Boats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords