China Aluminum Skin Sheets - 5052 Aluminum Checkered Plate for Boat Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

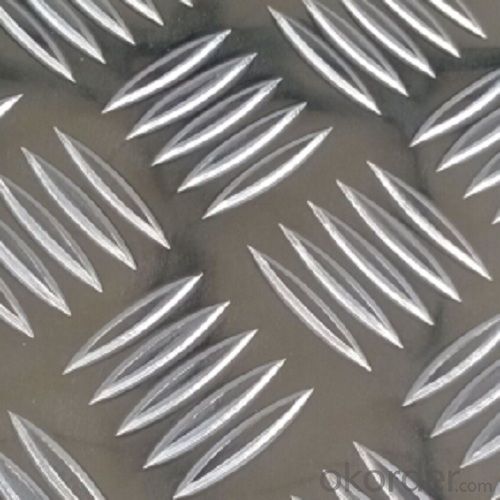

5052 Aluminium Checkered Plate for Boat Deck

l Production Introduction

1.Alloy number: 1100, 3003,1050,1060, 5052.

2.Temper: H14, H18, H12, H16, H22, H26, H24.

3.Brand: CMAX

4.Thickness: 0.8-10.0mm. width: 20-1600mm.

5.Tolerance: thick+/-0.02mm, width +/-0.5mm.

6.Pattern: two bars, three bars, five bars and diamond.

7.Surface brightness: bright surface or normall surface.

8.Application: trailer, truck, decking, flooring, stairs, steps, building industry.

9.Loading port: Shanghai

l Packaging & Delivery

Packaging detail: Wooden pallet, wooden case or as customer request.

Delivery detail: Within 25days

lCompany Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium checker plate is a popular product in CNBM. With best quality and service, we have won reputation around the world.

l CNBM World Wide

l Product Images and Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: Can 101 aluminum sheets be CNC machined?

- CNC machining is capable of processing 101 aluminum sheets, allowing for the creation of intricate and accurate cuts, holes, and shapes. This versatile and precise manufacturing process is commonly employed for aluminum materials. It involves computer-controlled machines that remove material from the sheets. The CNC machinability of 101 aluminum sheets is not restricted by their specific alloy designation. Nevertheless, to achieve optimal results, it is crucial to take into account factors like cutting parameters, tool selection, and feed rates when machining these sheets.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: Can aluminum sheets be used for air ducts?

- Indeed, air ducts can utilize aluminum sheets. Aluminum, known for its lightweight and durable characteristics, is frequently employed in air ducts. Its resistance to corrosion renders it a suitable option for HVAC systems. Air ducts are often constructed using aluminum sheets due to their malleability, enabling easy bending and shaping to meet specific dimensions. Moreover, aluminum boasts commendable thermal conductivity, ensuring efficient heat transfer within the ducts. Ultimately, opting for aluminum sheets in air ducts proves to be a pragmatic and efficient decision.

- Q: Are aluminum sheets flammable?

- No, aluminum sheets are not flammable. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and is known for its non-combustible properties. It does not burn or support combustion, making it a preferred choice for various applications where fire resistance is important, such as in the construction industry.

- Q: What are the different methods of surface protection for aluminum sheets?

- There are several different methods of surface protection for aluminum sheets. One common method is anodizing, which involves creating a protective oxide layer on the surface of the aluminum. This process involves immersing the sheets in an electrolyte solution and passing an electric current through them. The result is a thick, durable, and corrosion-resistant layer that can be further enhanced with various dyes and sealants. Another method is powder coating, where a dry powder is applied to the aluminum sheets and then cured under heat. This creates a hard and resistant coating that provides excellent protection against scratches, chemicals, and weathering. Powder coating is available in a wide range of colors and finishes, making it a popular choice for decorative purposes. Chemical conversion coating is another option, which involves treating the aluminum sheets with a chemical solution to convert the surface into a protective layer. This coating improves corrosion resistance and also provides a good base for paint or other coatings. Painting is also commonly used to protect aluminum sheets. Various types of paints can be applied to the surface, including epoxy, acrylic, and polyurethane-based coatings. These paints not only provide protection against corrosion and environmental factors but also offer aesthetic customization options. Lastly, laminating is a method where a protective film is applied to the surface of the aluminum sheets. These films can be made from various materials such as PVC, polyester, or polyethylene. Laminating provides an additional layer of protection against scratches, abrasion, and UV radiation. Each method of surface protection for aluminum sheets has its own advantages and considerations, depending on the specific requirements of the application. It is important to carefully assess the desired level of protection, aesthetic preferences, and budget constraints before selecting the most suitable method.

- Q: Can the aluminum sheets be used for manufacturing audio amplifier cases?

- Yes, aluminum sheets can be used for manufacturing audio amplifier cases. Aluminum is a popular choice for casing in audio equipment due to its lightweight yet durable properties. It provides excellent heat dissipation, which is crucial for audio amplifiers that generate heat during operation. Furthermore, aluminum can be easily machined and formed into various shapes, allowing for customization and aesthetics in the design of the amplifier case. Overall, aluminum sheets are a suitable material for manufacturing audio amplifier cases.

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets vary depending on the specific industry and application. However, some commonly accepted tolerances for aluminum sheets include thickness tolerances, flatness tolerances, and width and length tolerances. Thickness tolerances refer to the allowable variation in the thickness of an aluminum sheet. These tolerances can range from +/- 0.005 inches to +/- 0.010 inches, depending on the grade and thickness of the sheet. Flatness tolerances specify the degree of flatness or deviation from a perfectly flat surface that is acceptable for an aluminum sheet. Flatness tolerances can range from a few thousandths of an inch to a few hundredths of an inch, depending on the specific requirements of the application. Width and length tolerances define the allowable variation in the dimensions of an aluminum sheet. These tolerances can be specified in terms of +/- inches or as a percentage of the sheet's width or length. Generally, width and length tolerances for aluminum sheets are in the range of +/- 0.25 to +/- 0.50 inches. It is important to note that these standard tolerances are subject to change and can vary depending on the specific industry, customer requirements, and the capabilities of the manufacturer. Therefore, it is always recommended to consult the manufacturer or industry-specific standards to determine the precise tolerances for aluminum sheets in a particular application.

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: Can aluminum sheets be used for sign making?

- Yes, aluminum sheets can be used for sign making. Aluminum is a commonly used material for making signs due to its durability, lightweight nature, and resistance to rust and corrosion. It is a versatile material that can be easily cut, shaped, and printed on, making it suitable for various sign making applications.

Send your message to us

China Aluminum Skin Sheets - 5052 Aluminum Checkered Plate for Boat Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords