Tlc Aluminum Sheets Si 60 F254 for Construction - AA5005 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA5005 Used for Constrcution Description

Aluminum Sheets AA5005 Used for Constrcution has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA5005 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2.Main Features of Aluminum Sheets AA5005 Used for Constrcution

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

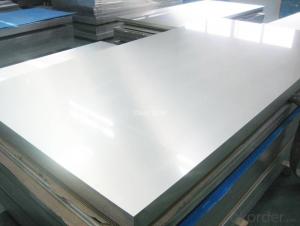

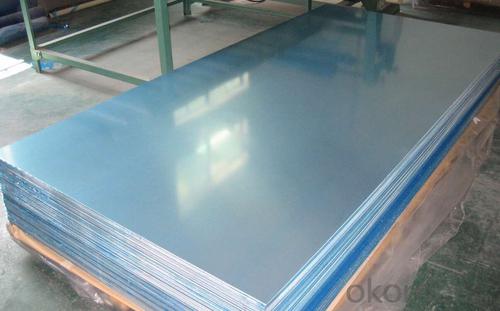

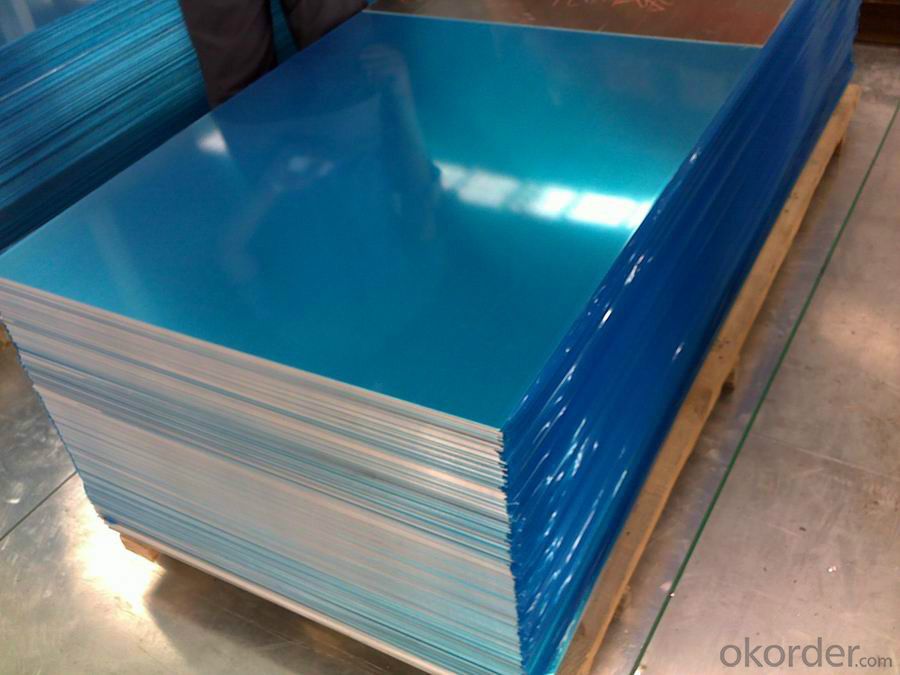

3.Aluminum Sheets AA5005 Used for Constrcution Images

4.Aluminum Sheets AA5005 Used for Constrcution Specification

Alloy | AA5005 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA5005 Used for Constrcution

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used for window frames?

- Indeed, window frames can be made using aluminum sheets. The utilization of aluminum for window frames is widespread because of its durability, lightweight characteristics, and ability to resist corrosion. Aluminum frames provide exceptional strength and stability and can be effortlessly tailored to suit any window size or shape. Moreover, aluminum frames necessitate minimal upkeep and can be painted or anodized to match any preferred color or finish. In summary, aluminum sheets serve as a versatile and dependable material for the construction of window frames.

- Q: Are aluminum sheets suitable for construction in regions with a high risk of earthquakes?

- <p>Aluminum sheets can be used in earthquake-prone areas, but their suitability depends on the specific application and construction methods. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it lacks the strength and rigidity of traditional materials like steel and concrete. When used in construction, aluminum must be properly engineered and combined with other materials to ensure structural integrity and compliance with seismic building codes. It's crucial to consult with structural engineers and follow local regulations when considering aluminum for earthquake-prone regions.</p>

- Q: What specific considerations or precautions need to be taken into account when working with thin aluminum sheets?

- <p>When working with thin aluminum sheets, it's important to handle them carefully to prevent denting or bending. Use gloves to avoid oils and moisture from hands that can cause corrosion. Ensure proper ventilation when cutting or shaping to avoid inhaling aluminum dust. Use sharp tools to minimize the risk of tearing or marring the surface. Also, consider the specific alloy's properties, as different aluminum alloys have varying strengths and malleabilities. Always follow safety guidelines and use appropriate protective equipment.</p>

- Q: Is the process of installing aluminum sheets considered simple or straightforward?

- <p>Aluminum sheets are generally considered easy to install, especially with the right tools and some basic knowledge of construction or home improvement. They are lightweight, which makes handling and positioning them simpler compared to heavier materials. Installation typically involves measuring, cutting the sheets to size, and attaching them to a frame or substrate using screws or adhesives. Proper alignment and securing are crucial for a professional-looking finish. For complex installations or high structures, professional assistance may be necessary to ensure safety and adherence to building codes.</p>

- Q: Are aluminum sheets suitable for electrical conductors?

- Aluminum sheets are indeed suitable for electrical conductors. They are frequently employed as conductors in a variety of electrical applications due to their remarkable conductivity, lightweight nature, and relatively low cost in comparison to metals such as copper. With approximately 61% of copper's conductivity, aluminum serves as an efficient conductor for most electrical purposes. Power transmission lines, electrical wiring, bus bars, and numerous other electrical components commonly utilize aluminum sheets. However, it is crucial to acknowledge that aluminum possesses higher resistance than copper, necessitating larger cross-sections to carry the same current. Additionally, caution must be exercised to prevent overheating when employing aluminum sheets as electrical conductors, as they have a lower melting point than copper.

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess a range of physical properties that make them highly sought-after in numerous applications. Firstly, they are lightweight, weighing only about one-third of steel at a density of approximately 2.7 grams per cubic centimeter. This characteristic makes aluminum sheets easy to handle and transport, reducing overall weight in structures or products. Additionally, aluminum sheets demonstrate exceptional resistance to corrosion. When exposed to air, a thin, protective oxide layer forms on their surface. This oxide layer acts as a barrier, preventing further oxidation and corrosion. As a result, aluminum sheets are well-suited for outdoor applications and environments with high humidity or exposure to corrosive substances. Moreover, aluminum sheets possess good thermal conductivity, enabling efficient heat transfer. This feature makes them commonly used in heat exchangers, radiators, and other cooling systems. Another noteworthy physical property of aluminum sheets is their high electrical conductivity. Aluminum is an excellent conductor of electricity, second only to copper. Consequently, it finds widespread use in electrical applications such as wiring, power transmission lines, and electrical equipment. In terms of appearance, aluminum sheets boast a bright, silvery-white color and a smooth surface finish, providing an aesthetically pleasing look. They can be easily shaped, formed, and machined, making them highly versatile and suitable for various manufacturing processes. Overall, the physical properties of aluminum sheets, including their lightweight nature, corrosion resistance, thermal conductivity, electrical conductivity, and ease of fabrication, contribute to their widespread use in industries such as aerospace, automotive, construction, and electrical engineering.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

Send your message to us

Tlc Aluminum Sheets Si 60 F254 for Construction - AA5005 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords