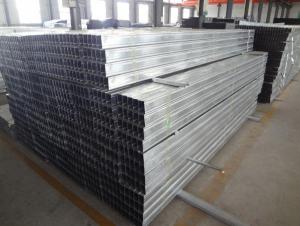

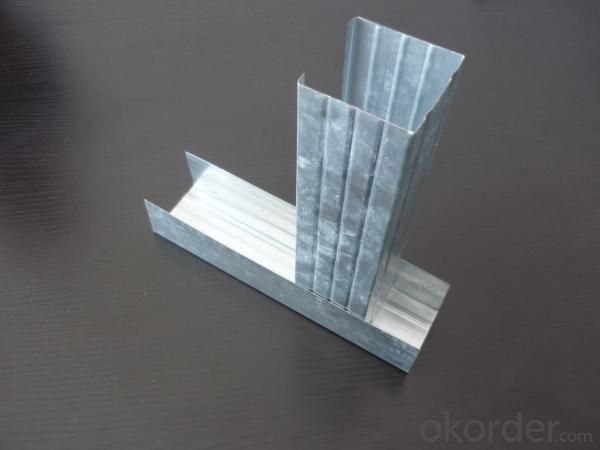

Open Cell Ceiling Grid Steel Profile for Partition

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X40HQ pc

- Supply Capability:

- 1X40HQ Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

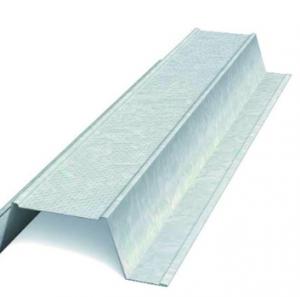

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

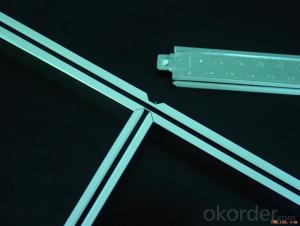

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: Φ8 light steel keel boom is how much?

- Do pull the experiment to know the top burst out of the boom will not break off In the beam generally around 300KG

- Q: How to remodel kitchen with dropped ceiling?

- Depends on what is above the ceiling tile, assuming that you have a grid and tile drop ceiling. If all that is above the drop ceiling is drywall or plaster, I would remove the grid, patch and paint to get the taller ceiling back unless it is ridiculously high.

- Q: does anyone know where I can find clips to hang things from acoustic ceiling grids?

- Hardware store, probably.

- Q: Light steel keel is what material to do

- Construction process: 3.1 process: ball line, sub-file → do pillow belt (design requirements) → fixed along the top, along the keel → fixed keel keel → installation of vertical keel → installation doors, window frames → installation of additional keel → installation support keel → check keel installation → electrical pipe installation wall equipment → install a mask panel → fill the sound insulation material → install another panel panel → seam and angle treatment → quality inspection

- Q: Mainly check the contents of which piece of people

- Acceptance of qualified after the supervision (or contractor project person in charge) signature

- Q: We recently did a kitchen renovation which involved taking a wall down between the kitchen and dining room. My house was build in the 50s and the ceilings are plaster over chicken wire (which we've learned on previous housework is excruciating work to remove as its screwed in a grid pattern every 6 inches so we're trying to salvage instead of replace). Here's the problem: The dining room ceiling is a textured plaster- the kitchen was a smooth gloss paint. Now that they are one room with the wall removed, there's not only the two different ceilings but also a patch of drywall between them where old cabinets used to hang. Im looking to texture it all- meaning I have to prep and attempt to match the flat glossy ceiling to the textured dining room. I don't even know where to start here. Help!

- When we encounter this, we find it much easier to float the entire ceiling, new and old, with mud to create a smooth surface. Then come back and re-texture the entire ceiling. Even though matching the wall texture might be tough, it is harder to tell a difference in textures at the wall-to-ceiling corner than it is in the center of a ceiling. If you install crown moldings, then it hides the different textures even more. Sure, this costs more than just patching the texture, but it comes down to whether or not you can live with the noticeable difference in texture on your ceiling. In renovation, you almost always get what you pay for.

- Q: While I won't get into the reasons why, I ended up drywalling my walls in a small sitting room in my basement before doing the ceiling. The walls have since been painted. What are my options for installing drywall in the ceiling and what types of roadblocks may I encounter when doing so?

- With no offense, OOPS. In any case it isn't a capital offense crime. After installing thousands of sq. ft. of drywall I offer that the process will be much the same as if the walls were still just studs. Certainly a helper or two would be nice, but the job can be tackled by a single, with some effort. If you have two like sized step ladders they can help. You can make braces from 2 x 4's to hold up a sheet, once you manage to get it up. The braces can also be used to boost: the sheet to the ceiling then wedge/hold it in place. Once screwed to the rafters/ joists all you need do is tape, mud, sand, and eventually paint. If you happen to NEED it white you can mask off your walls at the meeting points. I've also applied thousands of gallons of paint and have a suggestion. Assume your walls are a color. It is a trick of the eye perhaps, but glaringly noticeable to anyone if the painter didn't have a steady hand, and happened to get color up onto the ceiling. The better process for a DIY especially, is to cut the ceiling down onto the walls, and then paint the wall color to within 1/16th inch of the ceiling in a masked, straight line. Odd how it works, but it does. Steven Wolf

- Q: How to calculate the number of light steel keel required per level of various materials

- Not less if the room too much too small, it may not be enough, need to consider the increase in the main vice keel! The main keel spacing in the 800-1200, vice keel 600

- Q: My family bathroom and living room between the non-load-bearing walls, do not want to tear down all, just want to bathroom door from the left side of the wall to the right. Decoration said, do light steel keel wall to the left side of the door plug. So there will be no problems with the toilet tiles ah?

- The left side of the door plug, the plug network, pull hair! The next step on the line

- Q: Decoration, said light steel keel gypsum board wall what is the use?

- Light weight, strength to meet the requirements. Gypsum board thickness is generally 9.5-15mm, weight per square meter only 6-12Kg. Light steel keel with two paper gypsum board middle folder light steel keel is a good wall, the wall weight per square meter at 23Kg, only about 1/10 of the ordinary brick wall. With the gypsum board as the wall material, its strength can meet the requirements, the thickness of 12mm gypsum board longitudinal fracture load of up to 500N or more.

Send your message to us

Open Cell Ceiling Grid Steel Profile for Partition

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X40HQ pc

- Supply Capability:

- 1X40HQ Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords