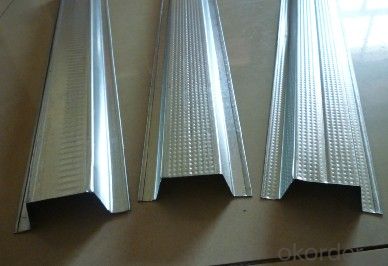

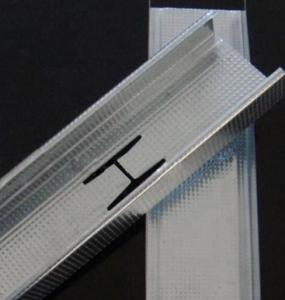

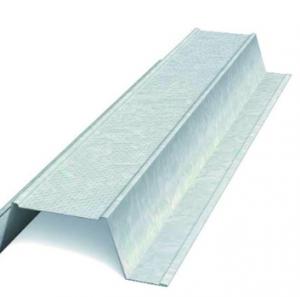

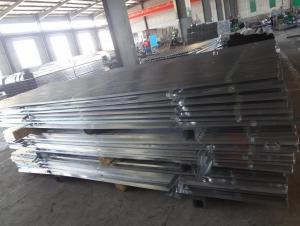

Galvanized Steel Ceiling Profile for Drywall Partition System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Lightgage Steel Joist

1.according to standard of GB/T11981-2001

2.adopting advanced domestic equipment

3.modern technique

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

3.Image

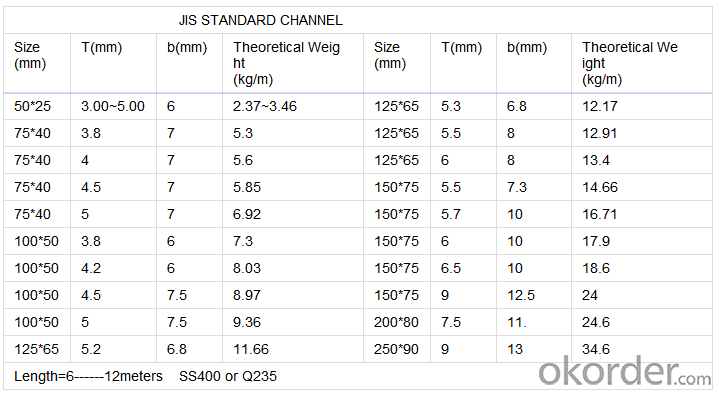

4.Detailed Specification

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

5.FAQ

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

- Q: Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- Thirty centimeters This is the standard necessary distance

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- 1-1.2mm thick

- Q: Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- Home decoration on the process requirements are higher.With the wooden keel to make the framework easy to correct .. so that the ceiling is not easy to deformation in the installation, after all, is the wood due to changes in the weather season, there will be hot up cold shrinkage. When the decoration is generally required for the wooden keel frame fixed. Fixed in the ceiling keel should be every 60 cm should play an expansion screw. The next well-shaped frame should be bayonet handle, gun nail fixed. Well shape frame every 30 cm The wood keel is a flammable material, no fire .. at the price of wood keel than light steel keel is higher .. now wood keel one meter at least 2 yuan. , Light steel keel need to be placed side by side .. Light steel keel because the specifications are too long, not suitable for use in the family, because the home decoration is not like a tooling decoration ceiling is a large area with light steel keel is drawn, The family can not draw, but also a reason is the family ceiling because the area is only part of the use of light steel keel is not to do. Must be the wooden keel frame can be .. so in the home decoration with wood keel is the best choice.

- Q: Construction schedule of light steel keel ceiling

- Two woodworking a painter, measuring the elastic line, punching the security boom, the main, the second keel day, adjust the reinforcement keel, install the gypsum board, screw rust treatment, paste kraft paper (caulking) one day. Putty (at the end) playing sandpaper on the wall paint (three at the end of both sides), a total of five days, two carpentry two days, four days of paint workers.

- Q: Light steel keel ceiling and wall construction technology

- This is the most basic, but pay attention to the height of the fire pipe and ventilation pipe, pay attention to the point 1 to find the lowest point of the pipe, the length of the ribs (expansion screw length plus the top of the pipe to the lowest point On the length of the hook) if long, with a hand sand machine cutting. 2 wall around to play wooden keel, the main bone fixed with. (To find a good level) 3 overall layout to be on both sides of the low, the middle raised 2 cm (the middle of the force, long will be under the draw) 4 ventilation layout to calculate the need to cut the main sub-keel, then Mineral wool board according to the size of cut (need to use steel wire reinforcement)

- Q: How to pick the ceiling keel

- The keel is an indispensable part of the decoration ceiling, which includes wood keel and light steel keel. Use wood keel to pay attention to the wood must be dry. Now most of the home decoration is not easy to deformation, with fire performance of light steel keel, selection should pay attention to the thickness of the keel, preferably not less than 0.6 mm ceiling metal keel is generally made of light steel and aluminum alloy, with light weight , Rigidity, fire and seismic performance is good, easy to install and so on, according to profile section points, there are U-keel and T-keel.

- Q: There are several specifications for light steel keel with household ceiling

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm. Under normal circumstances, the use of paper gypsum ceiling when most people will choose light steel keel, thin gypsum board using Pu keel, gypsum thick to use thick keel. There are two kinds of galvanized galvanized, one is hot galvanized, one is cold galvanized. Hot galvanized prices are high and cold galvanized prices are low. The ceiling keel consists of the keel (main keel), the cover keel (auxiliary keel) and various accessories. D38 (UC38), D50 (UC50) and D60 (UC60) three series. D38 for hanging point spacing 900-1200 mm not on the ceiling, D50 for hanging point spacing 900-1200 mm Master ceiling, D60 for hanging point spacing 1500 mm Master heavier ceiling, U50, U60 for the cover keel, it With the use of keel. The wall keel consists of horizontal keel, vertical keel and cross brace and various accessories. There are four series of Q50 (C50), Q75 (C75), Q100 (C100) and Q150 (C150) The width of the light steel keel is often used to refer to the keel model, such as the width of 50mm keel is called the 50 keel. Light steel keel side of the high known as the keel side of the high. Keel length is divided into 3 meters, 4 meters two. Keel each price between 12-20 yuan. Paper gypsum board per standard 2400 mm × 1200 mm) price between 22-30 yuan. Plus auxiliary materials costs and labor costs, the general light steel keel partition wall decoration price between 90 to 150 yuan per square meter. There are T line, C-shaped, U-shaped keel and so on.

- Q: Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated ceiling to be installed naturally nothing to ceiling accessories - keel. So, the ceiling keel on the ceiling plays a clear support, fixed role. Wood keel ceiling is good or light steel keel ceiling is better? It has a fire and rust anti-aging and other characteristics, but also in the construction of convenient, decorative effect is also very good. Light steel keel is relatively heavy, a long time more or less there will be sagging tendencies. Advantages and Disadvantages of Integrating Ceiling with Wood keel and Light Steel Now the light steel keel generally have been treated with paint, moisture, waterproof performance trustworthy, with a lot of performance. The wood keel light, easy to install and the price is relatively low, but there are some children defect. Wood keel because the main body is wood, it is easy to burn and corrosion, easy to mold in the wet bathroom, which the whole ceiling will cause a great impact. Of course, now a lot of wood keel have done anti-corrosion treatment, but also the surface of the wooden keel is also painted fire protection materials. This greatly improved the role of wood keel. In general, the wood keel ceiling or light steel keel ceiling is good, they have their own advantages, in fact, now with the development of society, integrated ceiling are more light steel keel.

- Q: The difference between light steel keel ceiling and macadam ceiling

- The former light weight, you can easily hang a variety of modeling top, which is estimated that no advantage, weight heavier, install trouble, etc.!

- Q: Home decoration living room ceiling (light steel keel or wood keel) between the two, what is the difference?

- I am a professional engaged in decoration. Most of the home decoration with wooden keel ceiling, durable and modeling can be done at will. Light steel keel is generally a large shopping malls hotel using the ceiling way, cost less than the keel, the disadvantage is noisy, modeling a single. Hope to adopt.

Send your message to us

Galvanized Steel Ceiling Profile for Drywall Partition System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords