Landscaping Geotextile Fabric - Non Woven Geotextile 300g/m2 100% Polyester

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

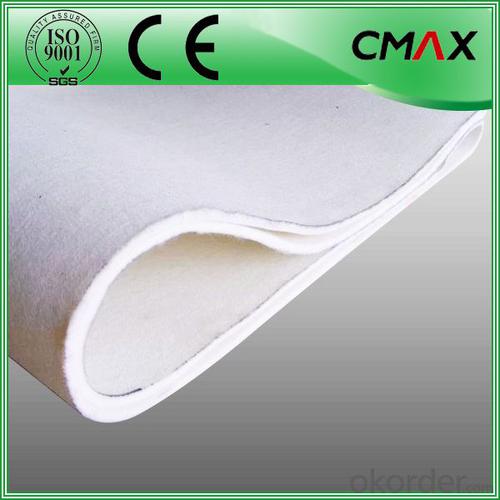

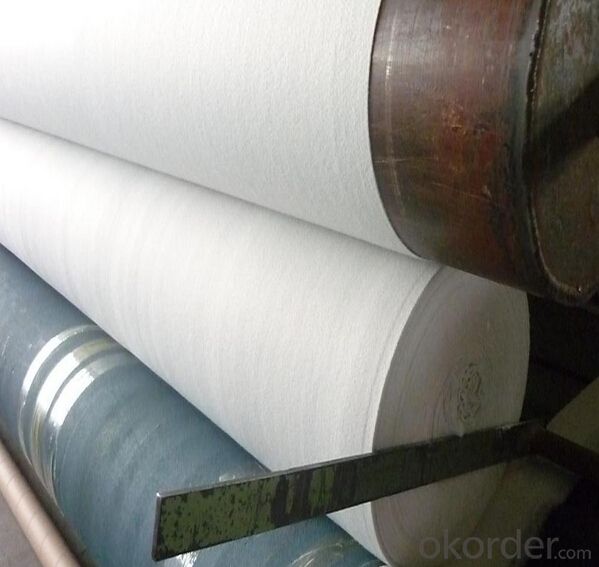

Non Woven Geotextile 300g m2 100% Polyester

Desciriptions:

Non Woven Geotextile 300g m2 100% Polyester are the preferred products for lining projects requiring low permeability ,corrosion protection , exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy ,

vapor barriersand waste water treatment in the line of industry and aquaculture and agriculture projects.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

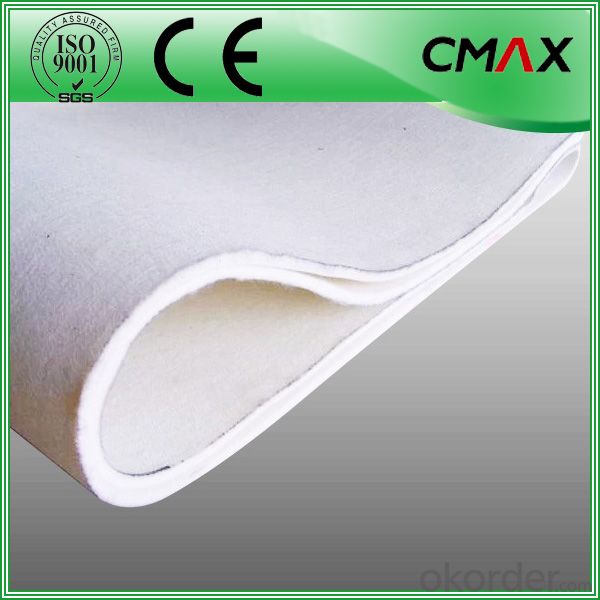

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: 400g / m2 two cloth a layer of water permeable geotextile technical requirements

- Two cloth a film will not be permeable, the composite film index breaking strength 5kn top broken 1.1kn tear 0.15kn peel 6n / cm or substrate fracture without stripping, the current 2008 standard weight has not been required, the original standard For not less than 360 grams

- Q: How are geotextiles used in railway construction?

- Geotextiles are used in railway construction to provide stabilization, separation, and filtration functions. They are placed beneath the ballast layer to prevent the mixing of fine particles with the ballast, thus maintaining its stability. Geotextiles also help in the filtration of water, preventing the migration of fines into the drainage system. Additionally, they act as a barrier that separates different layers of the railway structure, reducing the potential for intermixing and improving overall performance and longevity.

- Q: What are the geotechnical test test items for highway engineering? The

- Unit area weight or tensile strength, CBR burst strength, these two are the most basic, the other is not too important

- Q: How do geotextiles help in vegetation establishment?

- Geotextiles help in vegetation establishment by providing a stable and favorable environment for plant growth. They help to retain moisture in the soil, prevent erosion, and control weed growth. Additionally, geotextiles also protect the roots of plants from external damage and provide thermal insulation.

- Q: What are the advantages of using geotextiles in wetland restoration projects?

- There are several advantages of using geotextiles in wetland restoration projects. Firstly, geotextiles provide effective erosion control by stabilizing the soil and preventing it from washing away during heavy rainfall or flooding. This helps in maintaining the wetland's structure and preventing further degradation. Secondly, geotextiles act as a barrier, preventing the migration of harmful substances such as pollutants or excess nutrients from adjacent areas into the wetland, thus protecting its ecological integrity. Additionally, geotextiles can enhance vegetation growth by retaining moisture in the soil, promoting root development, and preventing weed growth. This ultimately contributes to the overall success of wetland restoration efforts.

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter fabric to prevent the migration of fine particles into the drainage system, while allowing water to flow through. By placing geotextiles behind the retaining wall, they help to enhance the drainage efficiency and overall stability of the system.

- Q: Do geotextiles affect soil pH levels?

- No, geotextiles do not affect soil pH levels as they are primarily used for erosion control and soil stabilization rather than altering the chemical composition of the soil.

- Q: Can geotextiles be used for filtration of contaminants in water?

- Yes, geotextiles can be used for filtration of contaminants in water. Geotextiles are permeable fabrics that can effectively filter and separate particles, including pollutants, sediment, and other contaminants, from water. They are commonly used in various applications such as wastewater treatment, stormwater management, and erosion control to improve water quality by removing harmful substances.

- Q: What are the considerations for geotextile selection in coastal engineering projects?

- When selecting geotextiles for coastal engineering projects, several considerations need to be taken into account. First, the geotextile should have a high tensile strength and durability to withstand the harsh coastal environment, including wave action and fluctuating water levels. It should also possess excellent filtration properties to prevent the migration of fine particles while allowing water to pass through. Additionally, the geotextile's permeability and hydraulic conductivity should be considered to ensure proper drainage and avoid the buildup of hydrostatic pressure. The material's resistance to biological degradation and UV radiation is crucial for long-term performance. Lastly, the geotextile should be compatible with the surrounding materials and easy to install and maintain, minimizing disruptions to the coastal ecosystem and reducing overall project costs.

Send your message to us

Landscaping Geotextile Fabric - Non Woven Geotextile 300g/m2 100% Polyester

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords