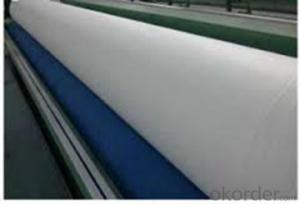

Polyester Nonwoven Geotextile Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

made of polyester or polypropylene fiber

good burying, hydrolyzation & corrosion resistibility

Density | Thickness | Breaking Strength | Elongation of Fracture | CBR Bursting Strength | Vertical Penetration Parameter | Equivalent Aperture |

g/m2 | mm | KN/m | % | KN | cm/s | O95 mm |

65 | 1.2 | 2.8 | 40 ~ 80 | 0.7 | K x (10-1 ~ 10-3)

(K = 1.0 ~ 9.9) | 0.07 ~ 0.2 |

75 | 1.4 | 3.3 | 0.8 | |||

100 | 1.6 | 5.0 | 0.95 | |||

150 | 1.52 | 7.5 | 1.5 | |||

160 | 2.0 | 8.5 | 1.60 | |||

200 | 2.4 | 11 | 2.10 | |||

250 | 2.8 | 14 | 2.60 | |||

300 | 3.4 | 16 | 3.20 | |||

400 | 4.0 | 21 | 4.0 | |||

500 | 4.5 | 25 | 4.8 |

- Q: Do you need a cushion on the ground floor?

- Chalet recommended to do sloping roof, the lowest point suggested 2.4. Talk about the ground, the roof, the wall area divided by the length of your board length and width of the area can be calculated on the amount of it!

- Q: The cushion is usually in the housing which parts

- Cushion is generally at the base, looking for the use.

- Q: When the cushion is used, the thickness of the protective layer is not less than ()

- Not on the roof: the general waterproof layer above can be used 15 ~ 25mm cement mortar protection.

- Q: Is it possible to make a waterproof layer

- 2, waterproof layer: In order to prevent the rain into the roof, groundwater into the wall, basement and underground structures, indoor water into the floor and walls and other materials layer.

- Q: Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- You can dig, but be careful not to use a strong earthquake with the machinery to remove, otherwise it will damage the original structure.

- Q: What is the relationship between the cushion and the ring beam?

- Ring beam is reinforced concrete. Is to increase the overall wall and overall stiffness, improve the side resistance performance, according to the earthquake or masonry specifications set. There may be in the ground wall, there may be in the underground wall.

- Q: Is foam concrete suitable for use as a cushion?

- The foamed concrete is a foaming system through a foaming machine that allows the foaming agent to be fully mechanically foamed and the foam is mixed evenly with the slurry.

- Q: Large area ground concrete cushion seam Why is the separation of joints generally concrete

- Second, sub-grid seam set In order to reduce the total shrinkage and temperature stress of the large area waterproof layer, avoid the leakage of the waterproof layer due to the deformation of the structural layer and the change of the temperature and humidity, the waterproof layer should be divided according to the shape, size and structure of the flat roof, Stay sewn. The waterproof layer is divided into several squares.

- Q: Why calculate the amount of time to count a lot of cushion ah

- Cushion cushion, as the name suggests is the structure of the liner layer, mainly from the back cover of the role, generally in the engineering design drawings have a clear approach (material).

- Q: Maintenance time of the cushion on the roof of the building

- According to the "concrete structure construction quality acceptance criteria" provides: Concrete should be poured within 12h after the completion of the concrete to be covered, and moisturizing conservation;

Send your message to us

Polyester Nonwoven Geotextile Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords