100% Polyester Filament Non-Woven Polypropylene Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

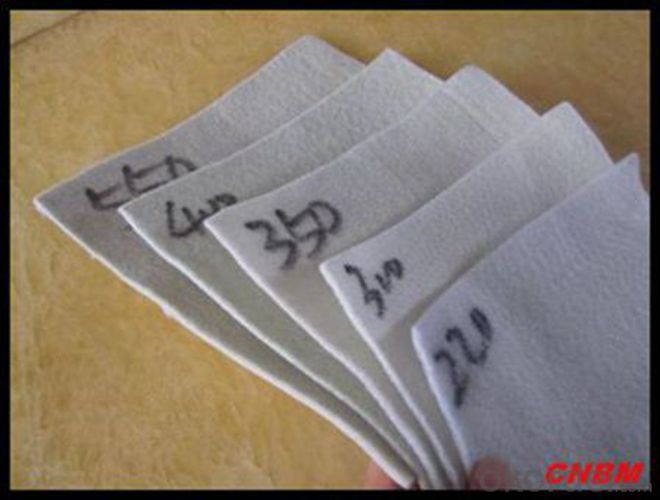

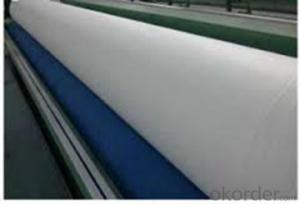

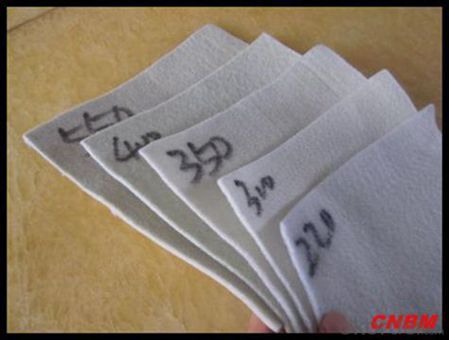

Specification

Product Features

Can self-seal small cracks while forming watertight laps at the seams.

Provides a strong mechanical bond to poured concrete.

Proven effective in structures under continuous or intermittent hydrostatic pressure-up to 70m (231 ft).

Can be installed in virtually any weather condition, including freezing temperatures and damp conditions. Can be installed on green concrete without primers or adhesives.

Proven effective in both vertical and horizontal applications-i.e., backfilled and property-line walls.

Application

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.Some commen uses of the material includes the following:

Road stabilization applications

Roofs

Civil applications

Railway work

Landfill lining

Trenches

Dams

Fitration under rip rap and rocks

Environmental applications

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles resistant to punctures and tears?

- Yes, geotextiles are generally designed to be resistant to punctures and tears. They are made from strong materials that provide durability and can withstand external forces, making them an effective solution for various applications requiring such resistance.

- Q: What are the benefits of using geotextiles in erosion control?

- Using geotextiles in erosion control offers several benefits. Firstly, geotextiles act as a barrier against soil movement and erosion, preventing the loss of valuable topsoil. They also help in stabilizing the soil by providing reinforcement and increasing its shear strength. Geotextiles allow water to pass through while retaining soil particles, thus reducing water runoff and sedimentation. Additionally, these materials are durable and resistant to degradation, ensuring long-term effectiveness in erosion control measures. By reducing erosion, geotextiles help protect natural habitats, prevent land degradation, and promote sustainable land management practices.

- Q: Can geotextiles be used in the construction of wastewater treatment plants?

- Yes, geotextiles can be used in the construction of wastewater treatment plants. Geotextiles are commonly used in various applications within wastewater treatment plants, such as filtration and drainage systems, erosion control, and soil stabilization. They help enhance the overall efficiency, durability, and environmental sustainability of the treatment plant infrastructure.

- Q: Can geotextiles withstand harsh weather conditions?

- Yes, geotextiles are designed to withstand harsh weather conditions. They are made from durable materials that can resist extreme temperatures, heavy precipitation, and UV radiation. Additionally, geotextiles have excellent drainage properties, ensuring they can handle excessive moisture and prevent erosion even in challenging weather conditions.

- Q: What is the purpose of using geotextiles in construction projects?

- The purpose of using geotextiles in construction projects is to provide reinforcement, separation, filtration, and drainage capabilities to improve the overall performance and longevity of the structures.

- Q: How do geotextiles contribute to soil stabilization?

- Geotextiles contribute to soil stabilization by providing a barrier that prevents soil erosion, while still allowing water to drain through. They distribute the weight of the load evenly, reducing the chances of soil compaction and settling. Additionally, geotextiles help in reinforcing the soil, increasing its shear strength and stability.

- Q: How do geotextiles help with soil erosion control?

- Geotextiles help with soil erosion control by providing a physical barrier that stabilizes the soil and prevents erosion. They are specifically designed to allow water to pass through while retaining soil particles, which helps to reduce the velocity of water flow and minimize erosion. Additionally, geotextiles can increase soil strength and stability, improve vegetation establishment, and enhance overall erosion resistance in various applications such as road construction, embankments, and slope stabilization.

- Q: How do geotextiles help with soil stabilization in construction sites?

- Geotextiles help with soil stabilization in construction sites by reducing soil erosion, improving soil structure, and enhancing the overall stability of the construction area. They are placed beneath the soil surface to prevent the migration of fine particles, distribute loads evenly, and provide reinforcement to the soil. This helps in controlling soil movement, increasing the bearing capacity of the ground, and ultimately ensuring a more secure and durable construction foundation.

- Q: Which big god has the relevant documents? bow down!

- Mainly from the anti-seepage, to prevent the role of soil erosion, I am specializing in the production of geotextiles, wish smooth

- Q: Can geotextiles be used in groundwater protection systems?

- Yes, geotextiles can be used in groundwater protection systems. Geotextiles are permeable fabrics that allow water to pass through while filtering out contaminants. They can be used as a protective barrier to prevent the migration of pollutants into groundwater sources, acting as a physical barrier and filtration system.

Send your message to us

100% Polyester Filament Non-Woven Polypropylene Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords