Woven Geotextile 200g m2 Non Woven Geotextile 300g m2

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Woven Geotextile 200g m2 Non Woven Geotextile 300g m2

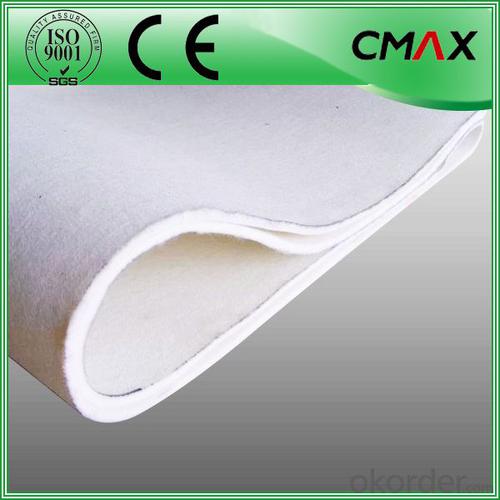

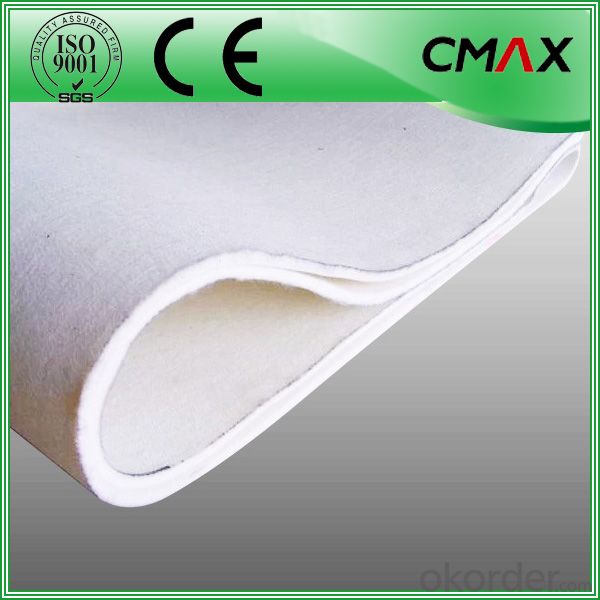

Desciriptions:

Non Woven Geotextile 300g m2 are the preferred products for lining projects requiring low permeability ,corrosion protection , exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy ,

vapor barriersand waste water treatment in the line of industry and aquaculture and agriculture projects.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

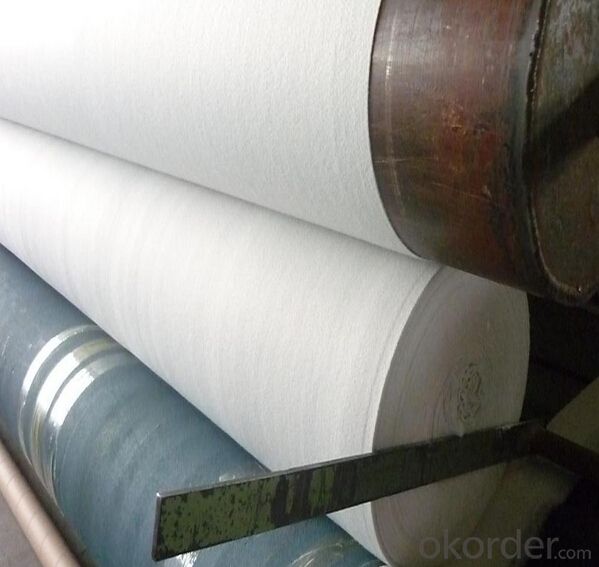

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: After the laying of drainage board and then need to lay a layer of geotextile it?

- Yes, from the role of filtration, over the water, but to prevent clogging, I professional production

- Q: Can geotextiles be used for livestock waste management?

- Yes, geotextiles can be used for livestock waste management. They can be employed as liners for waste storage structures such as lagoons or as covers to prevent odors and control the release of gases. Geotextiles can also be used to separate or filter waste materials, preventing soil contamination and promoting proper drainage.

- Q: Are geotextiles resistant to freeze-thaw cycles?

- Yes, geotextiles are typically resistant to freeze-thaw cycles. They are designed to withstand extreme weather conditions, including freezing temperatures and repeated cycles of freezing and thawing without significant deterioration or damage.

- Q: Can geotextiles be used in agricultural waste management systems?

- Yes, geotextiles can be used in agricultural waste management systems. They are often used for soil stabilization, erosion control, and filtration in agricultural applications, including waste management systems. Geotextiles can help to prevent soil erosion, filter out pollutants, and promote water drainage in these systems, making them an effective solution for managing agricultural waste.

- Q: How do geotextiles help with reinforcement of steep slopes?

- Geotextiles help with the reinforcement of steep slopes by providing stability and preventing erosion. They are often used as a reinforcement material to increase the shear strength of the slope and improve its overall stability. Geotextiles help distribute the load across the slope, reducing the risk of landslides or slope failure. Additionally, they allow for effective drainage, preventing the accumulation of water behind the slope, which can further weaken it.

- Q: What is the use of the black network when the shop is paved?

- It is geogrid, can enhance the overall strength of the roadbed, from the role of tensile, mostly polyethylene materials.

- Q: Can geotextiles be used in erosion control in agricultural fields?

- Yes, geotextiles can be used in erosion control in agricultural fields. Geotextiles provide a barrier that helps prevent soil erosion by stabilizing the soil and reducing water runoff. They can be used in various erosion control applications such as slope stabilization, sediment control, and erosion prevention on agricultural fields.

- Q: How do geotextiles aid in the protection of geomembranes?

- Geotextiles aid in the protection of geomembranes by acting as a barrier between the geomembrane and the surrounding soil or aggregate. They provide cushioning and support, preventing direct contact and potential damage to the geomembrane from sharp objects or uneven surfaces. Additionally, geotextiles can assist in preventing soil erosion and the migration of fine particles, enhancing the overall stability and longevity of the geomembrane installation.

- Q: Tunnel longitudinal drainage pipe with geotextile wrapped after the need for waterproof board wrapped, why can not be wrapped with a waterproof board

- You should say that the drainage pipe should be seepage of plastic blind tube it. Geotextile wrapped in the role is to play a filtering effect, filter the water to drain the sediment. Chong Hong geotextile material manufacturers

- Q: What are the design considerations for geotextile-reinforced retaining walls?

- The design considerations for geotextile-reinforced retaining walls include factors such as the type and strength of geotextile material, soil characteristics, wall height, slope stability, drainage system, and construction techniques. These considerations are important to ensure the stability, durability, and functionality of the retaining wall.

Send your message to us

Woven Geotextile 200g m2 Non Woven Geotextile 300g m2

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords