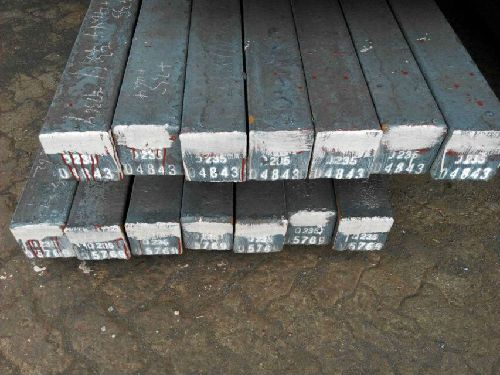

new producinh square steel;square bar, billet in sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

- Q: Can a steel square be used for other materials besides wood?

- Indeed, a steel square has the capacity to serve beyond wood. Widespread in carpentry and various trades, this versatile tool proves invaluable for gauging and delineating perpendicular angles. Crafted from steel, a resilient and enduring substance, it endures the strain and abrasion imposed by diverse materials. Although traditionally linked to woodworking, a steel square is equally adept at measuring and marking right angles in alternative mediums like metal, concrete, and plastic. Its unwavering precision and robustness establish it as a dependable instrument for meticulous measurements and layout tasks across multiple materials.

- Q: What are some common mistakes to avoid when using a steel square?

- Some common mistakes to avoid when using a steel square include not properly aligning the square with the workpiece, applying excessive force while using the square, not ensuring that the square is square to the workpiece, and not securely holding the square in place while making measurements or marking lines.

- Q: Can a steel square be used for checking the flatness of concrete slabs?

- No, a steel square is not suitable for checking the flatness of concrete slabs. A steel square is primarily used for measuring right angles and laying out lines, not for evaluating the levelness or evenness of surfaces. A better tool for checking the flatness of concrete slabs would be a straightedge or a laser level.

- Q: Can a steel square be used for checking the levelness of bookshelves?

- No, a steel square is not suitable for checking the levelness of bookshelves. It is primarily used for measuring angles and ensuring squareness in woodworking and construction projects. For checking the levelness of bookshelves, a level tool should be used instead.

- Q: You need to light steel keel wall square steel

- Needed. The material of the light steel keel partition wall is galvanized iron plate, the pressed keel and the gypsum board (or calcium silicate board), its merit is the light weight, easy to walk the electric wire tube, the construction is quick. But the fire is not good, it is dry work. The cost is higher.

- Q: What are some common techniques for using a steel square in cabinetry?

- A steel square, also known as a framing square or carpenter's square, is a versatile tool commonly used in cabinetry for measuring and marking angles, ensuring accurate cuts and joinery. Here are some common techniques for using a steel square in cabinetry: 1. Checking for squareness: One of the primary uses of a steel square is to check if a corner is perfectly square. Place the square against the inside corner, and if the edge aligns with the adjacent edge, the corner is square. This helps in ensuring all corners of the cabinets are at right angles. 2. Marking 45-degree cuts: The steel square has a 45-degree angle marked on its body. By aligning the square with the edge of the material, you can mark a precise 45-degree angle for mitered cuts, such as for trim or decorative elements on cabinet doors and panels. 3. Marking parallel lines: The long edge of a steel square is used for marking parallel lines. Simply align the square with the edge of the material and draw a line along the other edge of the square. This technique is helpful for marking shelf and cabinet bottom locations or ensuring parallel cuts. 4. Laying out cuts: The steel square is excellent for marking accurate lines for cuts. By aligning the square with the edge of the material, you can draw a line perpendicular or parallel to the edge. This helps in marking cuts for cabinet components like shelves, drawer dividers, and door frames. 5. Determining pitch and slope: A steel square can be used to determine the pitch or slope of a roof or any inclined surface. By placing the square on the surface, you can read the pitch or slope degree based on the markings on the square. 6. Measuring and transferring dimensions: The steel square can also be used as a ruler for measuring and transferring dimensions. The body of the square usually has a scale on one or both edges, allowing you to measure and mark precise lengths or distances. Overall, a steel square is an indispensable tool in cabinetry, offering accuracy and versatility in measuring, marking, and verifying angles. Whether you're building cabinets from scratch or making precise modifications, incorporating these common techniques will help ensure your cabinetry projects are precise and well-crafted.

- Q: Can a steel square be used for cabinet-making projects?

- Yes, a steel square can be used for cabinet-making projects. A steel square, also known as a framing square or a carpenter's square, is a versatile tool commonly used in woodworking. It has a 90-degree angle and is often used to check and mark right angles, measure and mark straight lines, and ensure accuracy during the construction of cabinets or other woodworking projects. The steel square is durable, precise, and can be a reliable tool for cabinet-making tasks such as measuring and marking lumber, checking the squareness of joints, or verifying the alignment of cabinet components. However, it is important to note that there are also specialized squares specifically designed for cabinet-making, such as cabinetmaker's squares or combination squares, which may offer additional features or benefits specific to cabinet-making tasks.

- Q: What are some common projects that require the use of a steel square?

- Some common projects that require the use of a steel square include carpentry and woodworking projects, such as framing, making accurate measurements, marking angles, and checking for squareness. It is also commonly used in construction projects for laying out foundations, checking diagonals, and verifying perpendicularity.

- Q: How do you use a steel square to determine the angle of a coping cut?

- To use a steel square to determine the angle of a coping cut, you need to follow a few simple steps. First, ensure that the square is properly aligned and perpendicular to the material you are working with. This will help you obtain accurate measurements. Next, place the square against the edge of the material, making sure that one arm of the square is aligned with the surface of the material and the other arm is pointing towards the direction of the coping cut. Once the square is in position, observe the scale or measurement markings on the square. Most steel squares have a protractor or angle measuring scale etched on one of the arms. This scale will help you determine the angle of the coping cut. Now, look for the angle reading that aligns with the edge of the material. This will be the angle at which you need to make the coping cut. Make sure to double-check your measurements and ensure that the square is firmly in place before making any cuts. It is also recommended to use a pencil or a scribe to mark the angle on the material for accuracy. Remember that practice and experience will improve your ability to accurately determine the angle using a steel square.

- Q: How do you use a steel square to determine the angle of a taper cut?

- To use a steel square to determine the angle of a taper cut, follow these steps: 1. Begin by marking the starting point of the taper cut on the material you are working with. 2. Place the steel square against the edge of the material, aligning one leg of the square with the starting point of the taper cut. 3. Hold the square firmly in place and adjust the other leg of the square until it aligns with the desired angle of the taper cut. For example, if you want to create a taper cut with a 45-degree angle, adjust the second leg of the square until it is parallel to the 45-degree line on the square. 4. Once the square is properly aligned, use a pencil or a marker to draw a line along the edge of the second leg of the square. This line will serve as a guide for your taper cut. 5. Carefully cut along the marked line using an appropriate tool, such as a saw or a chisel, depending on the material you are working with. By using a steel square in this manner, you can accurately determine the angle of a taper cut and create precise and consistent results. It is important to ensure that the square is held firmly in place and that the legs are properly aligned to achieve an accurate angle measurement.

Send your message to us

new producinh square steel;square bar, billet in sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords