HR Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of HR Square Steel:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q195 or equivalent.

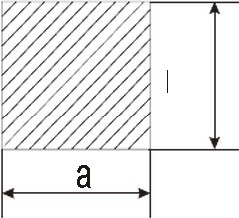

(The section of Square Steel)

Some details of HR Square Steel:

-List 1. Chemical Composition.

|

Standard |

Grade |

Element (%) | ||||

|

GB |

Q195 |

C |

Mn |

S |

P |

Si |

|

0.06~0.12 |

0.25~0.50 |

≤0.050 |

≤0.045 |

≤0.30 | ||

-List 2. Physical Properties

|

Grade |

Yield Point Δs/MPa |

Tensile Strength |

Elongation δ5% | ||

|

Steel diameter(mm) |

Steel diameter(mm) | ||||

|

≤16 |

16~40 |

≤16 |

16~40 | ||

|

≥ |

≥ | ||||

|

Q195 |

195 |

185 |

315~390 |

33 |

32 |

-List 3.The length of a side and the theoretical weight of HR Square Steel.

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

6 |

0.283 |

32 |

8.04 |

|

7 |

0.385 |

*33 |

8.55 |

|

8 |

0.502 |

34 |

9.07 |

|

9 |

0.636 |

*35 |

9.62 |

|

10 |

0.785 |

36 |

10.17 |

|

11 |

0.950 |

38 |

11.24 |

|

12 |

1.13 |

40 |

12.56 |

|

13 |

1.33 |

42 |

13.85 |

|

14 |

1.54 |

45 |

15.90 |

|

15 |

1.77 |

48 |

18.09 |

|

16 |

2.01 |

50 |

19.63 |

|

17 |

2.27 |

53 |

22.05 |

|

18 |

2.54 |

*55 |

23.6 |

|

19 |

2.82 |

56 |

24.61 |

|

20 |

3.14 |

*58 |

26.4 |

|

21 |

3.46 |

60 |

28.26 |

|

22 |

3.80 |

63 |

31.16 |

|

*23 |

4.15 |

*65 |

33.17 |

|

24 |

4.52 |

*68 |

36.3 |

|

25 |

4.91 |

70 |

38.49 |

|

26 |

5.30 |

75 |

44.16 |

|

*27 |

5.72 |

80 |

50.24 |

|

28 |

6.15 |

85 |

56.72 |

|

*29 |

6.60 |

90 |

63.59 |

|

30 |

7.06 |

95 |

70.85 |

|

*31 |

7.54 |

100 |

78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 4. The allowed tolerance of HR Square Steel:

|

Length of a side(mm) |

Allowed Tolerance | ||

|

Group1 |

Group2 |

Group3 | |

|

5.5~7 |

±0.20 |

±0.30 |

±0.40 |

|

7~20 |

±0.25 |

±0.35 |

±0.40 |

|

20~30 |

±0.30 |

±0.40 |

±0.50 |

|

30~50 |

±0.40 |

±0.50 |

±0.60 |

|

60~80 |

±0.60 |

±0.70 |

±0.80 |

|

80~110 |

±0.90 |

±1.0 |

±1.1 |

|

110~150 |

±1.2 |

±1.3 |

±1.1 |

|

150~190 |

―― |

―― |

±2.0 |

|

190~250 |

―― |

―― |

±2.5 |

Usage/Applications of HR Square Steel:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of HR Square Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of HR Square Steel:

- Q: What are some common accessories or attachments for a steel square?

- A steel square can be enhanced with various accessories and attachments, such as a scribe, protractor, ruler, and level. To mark lines or measurements on a surface precisely and straightly, a scribe is a pointed tool that can be attached to the square. For accurate angle measurements, a protractor can be attached to the steel square, which is particularly useful for projects requiring precise angles. A ruler is also a common attachment for a steel square, allowing for easy measurement of lengths and precise measurements in projects. Lastly, to ensure perfect leveling of a surface or object, a level can be attached to the steel square, providing accurate leveling measurements. This is especially important for projects that require precise alignment. By incorporating these accessories and attachments, a steel square becomes a versatile and functional tool, essential for carpentry, woodworking, and other construction tasks.

- Q: Can a steel square be used for measuring and marking compound bevel cuts?

- Yes, a steel square can be used for measuring and marking compound bevel cuts. A steel square is a versatile tool that can be used for various woodworking tasks, including measuring and marking angles for compound bevel cuts. However, it is important to note that a steel square alone may not provide the precise measurements required for compound bevel cuts. It is recommended to use additional tools, such as a bevel gauge or a protractor, to accurately determine the angles needed for compound bevel cuts.

- Q: Can a steel square be used for checking the alignment of brickwork?

- Indeed, the alignment of brickwork can be verified using a steel square. Carpenters and masons commonly employ this versatile tool to measure angles and alignments. Its structure consists of a right angle shape with one lengthy side and one shorter side. To ascertain the alignment of brickwork, the steel square can be utilized to ensure that the brick corners form perfect right angles. By placing the lengthy side of the steel square against the brick corner, one can visually inspect if the edges align suitably. If the corners are not at right angles, adjustments can be made to guarantee precise alignment. Moreover, the shorter side of the steel square can be utilized to measure the evenness of the brick courses. By positioning the shorter side across the brick face, one can examine if the courses are level and uniform. This is particularly advantageous in ensuring consistent mortar joints and straight brick laying. In conclusion, a steel square is an invaluable tool for verifying the alignment of brickwork, contributing to accurate and aesthetically pleasing construction.

- Q: Are there any special techniques for using a steel square in masonry work?

- Yes, there are several special techniques for using a steel square in masonry work. Firstly, it is important to ensure that the steel square is clean and free from any debris or dirt. This will help in achieving accurate measurements and angles. When using the steel square to measure and mark angles, it is recommended to hold the square firmly against the surface and use a pencil or chalk to mark the desired angle. This will ensure that the measurements are precise and consistent. Another important technique is to use the steel square as a guide when cutting or shaping bricks or stones. By aligning the square with the edge of the material, it can serve as a reference point to guide the saw or chisel, resulting in clean and accurate cuts. Furthermore, the steel square can also be used to check for squareness and alignment in masonry work. By placing the square against the corners or edges of the structure, it can help identify any discrepancies or deviations from a perfect 90-degree angle. This is particularly useful when constructing walls or laying bricks to ensure a sturdy and well-aligned structure. Overall, using a steel square in masonry work requires precision and attention to detail. By following these special techniques, it can greatly assist in achieving accurate measurements, angles, and alignment, ultimately resulting in high-quality masonry work.

- Q: What are some common misconceptions about using a steel square?

- One common misconception about using a steel square is that it is only used for making right angles. In reality, a steel square is a versatile tool that can be used for various measurements and layouts in woodworking and construction. Another misconception is that it is difficult to use or requires advanced skills. However, with a little practice and understanding of its different features, using a steel square can be quite straightforward and useful in many different tasks.

- Q: Can a steel square be used for insulation installation?

- Using a steel square for insulation installation is not possible. Steel squares are commonly utilized in construction and woodworking to measure and indicate right angles. However, insulation installation necessitates materials that can offer thermal resistance, such as fiberglass, foam board, or mineral wool. These materials are specifically engineered to capture air and hinder heat transfer, a capability that steel squares lack. Consequently, it is crucial to employ suitable insulation materials for a successful installation.

- Q: How do you use a steel square to measure a roof pitch?

- To use a steel square to measure a roof pitch, you will need to follow these steps: 1. Start by selecting a steel square that has a body and a tongue. The body is usually 24 inches long, and the tongue is usually 16 inches long. 2. Place the body of the steel square along the bottom edge of the roof rafter or truss. Ensure that the square is positioned in a way that the tongue extends vertically towards the peak of the roof. 3. Adjust the square until the edge of the tongue aligns with the bottom edge of the rafter or truss. 4. Once the square is positioned correctly, read the measurement on the body of the square where it intersects with the top edge of the rafter or truss. This measurement represents the rise of the roof. 5. Next, measure the horizontal distance along the body of the square from the bottom edge of the rafter or truss to the point where the tongue intersects the body. This measurement represents the run of the roof. 6. To determine the roof pitch, divide the rise measurement by the run measurement. This will give you a ratio, such as 4:12 or 6:12, which indicates the pitch of the roof. Remember, the pitch of a roof is measured as the vertical rise for every 12 inches of horizontal run. So, a 4:12 pitch means that for every 12 inches of run, the roof rises 4 inches vertically. Using a steel square to measure a roof pitch can be an accurate and convenient method, especially when working with traditional gable roofs. However, it is important to make sure the steel square is properly aligned and that the measurements are taken accurately to ensure precise results.

- Q: What are some common conversions and calculations that can be done with a steel square?

- A steel square, also known as a framing square or carpenter's square, is a versatile tool used in carpentry and woodworking. It consists of a long blade and a shorter tongue that meet at a right angle. Here are some common conversions and calculations that can be done with a steel square: 1. Measuring and marking: The steel square can be used to measure and mark straight lines or right angles on a piece of wood or other materials. It is particularly useful in determining 90-degree angles for accurate cuts and joint construction. 2. Determining squareness: By using the square's 90-degree angle, you can check the squareness of corners and ensure they are perfectly perpendicular. This is important for constructing frames, cabinets, and other structures. 3. Finding roof pitch: Carpenters often use a steel square to determine the pitch or slope of a roof. By placing the square on the roof surface and aligning it with the rafters, the angle of the roof pitch can be measured. 4. Calculating rafter lengths: A steel square can also be used to calculate the length of rafters for roofs. By using the square's markings and angles, carpenters can quickly determine the appropriate length of rafters needed for a specific roof design. 5. Making angle cuts: The steel square can be used to mark and guide angle cuts on wood or other materials. By aligning the square's blade or tongue with the desired angle and marking the cut line, precise angle cuts can be achieved. 6. Creating parallel lines: The square's straight edge can be used to draw parallel lines by simply sliding it along the edge of the material while keeping it aligned with the desired distance. 7. Measuring and transferring dimensions: The square can be used as a ruler or measuring device for both straight and diagonal measurements. It is useful in transferring measurements from one piece of material to another accurately. 8. Checking flatness: The steel square can also be used to check the flatness of a surface. By placing it on a flat surface and observing if the entire length is in contact, any deviations or unevenness can be detected. Overall, a steel square is a versatile tool that can be used for a wide range of conversions and calculations in carpentry and woodworking. Its ability to measure, mark, determine angles, and assist in various construction tasks makes it an essential tool for any carpenter or woodworker.

- Q: What are the different types of steel squares available on the market?

- There are several different types of steel squares available on the market, including framing squares, combination squares, try squares, and engineer squares. Each type has its own unique design and features that make them suitable for specific tasks and applications.

- Q: Can a steel square be used for laying out roof rafters?

- Laying out roof rafters can be achieved with the use of a steel square. This tool, also known as a framing square or carpenter's square, is highly versatile in carpentry and is capable of performing numerous tasks, including the laying out of roof rafters. It is composed of two arms positioned at a 90-degree angle, featuring engraved measurements and markings on its surface. To begin the process of laying out roof rafters with a steel square, the first step typically involves determining the pitch or slope of the roof. This can be accomplished through the consultation of building plans or with the aid of a pitch-finding tool. Once the pitch is established, the steel square can then be employed to mark the angles and measurements for each individual rafter. The steel square proves invaluable in marking the plumb cut and bird's mouth (notch) at the top end of each rafter, ensuring a proper fit and alignment. Additionally, it aids in establishing the length and angle cuts at the bottom end of each rafter, which will ultimately be attached to either the wall plate or ridge beam. All in all, the steel square represents a dependable and precise tool for laying out roof rafters, offering accurate measurements and angles that contribute to the successful installation of rafters.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

HR Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords