Hot-rolled Square Steel Bar With Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel Bar:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q235 or equivalent.

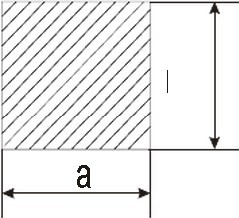

(The section of Square Steel)

Some details of Square Steel Bar:

-List 1. Chemical Composition.

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

-List 2. Physical Properties

Grade | Q235B | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | 235 | 225 | 215 | 205 | |

Tensile Strength | 375~500 | ||||

Elongation δ5% | 26 | 25 | 24 | 23 | |

-List 3.The length of a side and the theoretical weight of Square Steel.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 70 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 4. The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Raw material for square tubes.

Packaging & Delivery of Square Steel Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel Bar:

-Products details(Tag Marks):

-Square Steel Bar during the transportation:

- Q: How do you use a steel square to determine the slope of a roof?

- To use a steel square to determine the slope of a roof, you will need to follow these steps: 1. Position yourself at the bottom edge of the roof where you want to measure the slope. 2. Hold the steel square against the edge of the roof, with one arm resting on the roof surface and the other arm extending vertically. 3. Adjust the vertical arm of the steel square until it is perfectly plumb, meaning it is aligned with the vertical direction. 4. While keeping the steel square steady, observe the horizontal arm. Note that it has markings and numbers representing different angles, typically ranging from 0 to 90 degrees. 5. Identify the marking on the horizontal arm that aligns with the roof surface. For example, if the horizontal arm aligns with the roof at the 4-inch marking, you would consider this as a 4-inch rise over a 12-inch run. 6. Convert the rise and run measurements into a ratio or fraction to represent the slope. In this example, the ratio would be 4:12 or the fraction 1/3, indicating that the roof has a slope of 1/3 or 4:12. Remember that the markings on the steel square are typically standardized and designed for common roof slope measurements. However, it may be necessary to refer to a conversion chart or consult an engineer if the slope is outside the range of the steel square markings.

- Q: How do you choose the right size of steel square for a project?

- When it comes to selecting the appropriate size of a steel square for your project, there are several factors to take into account. To begin with, it is crucial to evaluate the scale and scope of your project. The load that the steel square will bear and the level of structural integrity it must provide should determine the size and weight requirements. These considerations will vary depending on the specific application, whether it is construction, fabrication, or general DIY work. Furthermore, the dimensions of the components or materials that will interact with the steel square should be considered. It should be of sufficient size to accommodate these elements, ensuring a proper fit and functionality. For instance, if the steel square is to be used as a support beam, it must be wide and thick enough to offer adequate strength. In addition, the physical space in which the project will take place should be taken into account. If there are limited clearance or tight quarters, opting for a smaller-sized steel square may be more suitable. Consulting structural engineering tables and industry standards can also prove to be helpful when determining the appropriate size of a steel square for your project. These resources provide guidelines on load-bearing capacities and recommended sizes for various applications. Lastly, seeking advice from professionals or individuals with experience in the field is always a prudent decision. They can provide insights based on their expertise, assisting you in selecting the ideal size of a steel square that meets your specific project requirements.

- Q: Can a steel square be used for checking the squareness of a floor tile?

- Yes, a steel square can be used for checking the squareness of a floor tile. A steel square is a tool commonly used in construction and carpentry to determine right angles and check for squareness. It consists of a metal ruler with a perpendicular handle, forming a perfect 90-degree angle. By placing the steel square against the edge of the floor tile, it can be used to verify if the tile is properly aligned and forms a right angle with the adjacent tiles or walls. This ensures that the tile installation is precise and the resulting floor is level and aesthetically pleasing.

- Q: What are some common accessories or attachments for a steel square?

- Some common accessories or attachments for a steel square include a scribe, protractor, ruler, and level. A scribe is a pointed tool that can be used to mark lines or measurements on a surface. It is often attached to the square to provide a precise and straight marking tool. A protractor is a device that can be attached to the steel square to measure angles accurately. It is particularly useful when working on projects that require precise angle measurements. A ruler is another common accessory that can be attached to a steel square. It allows for easy measurement of lengths and can be useful when working on projects that require precise measurements. Lastly, a level is an attachment that helps ensure that a surface or object is perfectly level. It can be attached to the steel square to provide accurate leveling measurements, which is particularly important when working on projects that require precise alignment. These accessories and attachments enhance the versatility and functionality of a steel square, making it an essential tool for carpentry, woodworking, and other construction tasks.

- Q: Building with steel or steel plate?

- It is recommended to use channel No. 12, and the span of three meters is not big, so the problem of vibration will not occur! Square steel tubes are not recommended for load-bearing structures. I'm from the steel installation department.It is suggested that the upper channel, the red plate, and the wood. It's more comfortable to use.

- Q: How do you use a steel square to lay out a perpendicular line on a curved surface?

- To create a perpendicular line on a curved surface using a steel square, follow these instructions: 1. Begin by identifying the desired location on the curved surface where you intend to establish the perpendicular line. This specific point is known as the reference point. 2. Position the steel square on the reference point, ensuring that one edge of the square aligns with the tangent of the curve at that particular point. The tangent represents a straight line that touches the curve specifically at that point. 3. After placing the steel square correctly, firmly hold it in place, and verify its alignment to the tangent line, confirming its perpendicularity. To confirm the square's alignment, you can utilize a bubble level or a plumb bob. 4. Once the square is properly aligned, utilize a pencil or marker to mark a line along the edge of the square, extending away from the curve. This marked line will be perpendicular to the tangent line and will function as your reference line for perpendicularity. 5. To validate the accuracy of the perpendicular line, measure the distance from the reference point to the perpendicular line at various points along its length. Consistent measurements would indicate that the line is indeed perpendicular. It is important to remember that achieving precise and accurate results when using a steel square to establish a perpendicular line on a curved surface necessitates careful alignment and attention to detail. Ensuring the square's perpendicularity to the tangent line is crucial.

- Q: How do you use a steel square for making precise 45-degree angle cuts?

- To use a steel square for making precise 45-degree angle cuts, follow these steps: 1. Start by ensuring that your steel square is clean and free from any debris or rust. This will help maintain accuracy during the cutting process. 2. Place your steel square on the material you wish to cut, ensuring that the longer side of the square is aligned with the edge of the material. For example, if you are cutting a piece of wood, align the square with the edge of the wood. 3. Hold the square firmly in place, making sure it doesn't move while you're working. 4. To create a 45-degree angle cut, you need to position the material at a specific angle against the square. For this, you can use the inner corner of the square as a guide. Align one of the edges of the material with the inner corner of the square. This will create a 45-degree angle between the square and the material. 5. Once you have the material properly aligned, use a pencil or a marking tool to trace along the edge of the square. This will create a precise line indicating where the cut should be made. 6. After marking the line, carefully remove the square and reposition it out of the way. Ensure that the material is secure and won't move during the cutting process. 7. Use an appropriate cutting tool such as a saw or a miter saw to cut along the marked line. Make sure to follow proper safety precautions and use the appropriate cutting technique for the tool you are using. 8. Take your time while cutting, ensuring that you follow the marked line accurately. Cutting slowly and steadily will help maintain precision and avoid any mistakes. By following these steps, you can effectively use a steel square to make precise 45-degree angle cuts. Remember to always measure and mark accurately, and use appropriate cutting tools to achieve the desired results.

- Q: How do you use a steel square for marking and cutting mortises?

- To mark and cut mortises using a steel square, follow the steps below: 1. Choose the appropriate size steel square for your project. The steel square is comprised of two arms perpendicular to each other, with one arm being longer than the other. The longer arm is known as the blade, while the shorter arm is referred to as the tongue. 2. Use a tape measure or ruler to measure the width of the mortise you intend to cut. Once you have determined the measurement, align the blade of the steel square with the wood's edge where you want the mortise to begin. 3. Firmly hold the steel square against the wood, ensuring that the blade is flush with the edge. Use a pencil or marking knife to mark a line along the tongue of the square, indicating the starting point of the mortise. 4. Proceed to measure the depth of the mortise. To accomplish this, position the square vertically against the wood's side, with the tongue against the top surface. Slide the square downwards until the blade reaches the desired depth. Mark this measurement on the wood's side using a pencil or marking knife. 5. Repeat this procedure on the opposite side of the wood to mark the other edge of the mortise. 6. Once you have accurately marked the starting point and depth of the mortise on both edges, utilize a chisel and mallet to commence the cutting process. Begin by making a series of shallow cuts along the marked lines, gradually increasing the depth with each pass. Take your time and exercise caution to ensure precise and clean cuts. 7. As you progress, periodically check the depth of the mortise against the marked measurement on the steel square. This will aid in maintaining the desired depth throughout the cutting process. Always remember to wear appropriate safety equipment, such as goggles and gloves, when working with chisels and other cutting tools. Additionally, practice on scrap wood before proceeding to your actual project in order to become familiar with the process and refine your skills.

- Q: Can a steel square be used for deck railing layout and installation?

- Yes, a steel square can be used for deck railing layout and installation. A steel square, also known as a framing square or carpenter's square, is a versatile tool that is commonly used in construction and woodworking for measuring and marking right angles. It has a long blade with measurements along its length and a shorter tongue perpendicular to the blade, forming an L-shape. When it comes to deck railing layout and installation, a steel square can be used to ensure accurate measurements and angles. It can help align the posts and balusters, ensuring that they are correctly positioned and evenly spaced. The measurements on the blade can be used to mark the exact locations for the railing components, while the right angle formed by the blade and tongue can be used to check for squareness and alignment. Additionally, a steel square can be used as a guide for cutting and shaping the railing components. Its straight edge can be used to draw straight lines or guide a circular saw or jigsaw for precise cuts. Furthermore, the tongue of the steel square can be used as a guide for marking and drilling holes in the railing components. Overall, a steel square is an essential tool for deck railing layout and installation. Its accuracy and versatility make it suitable for ensuring precise measurements, angles, and alignment during the construction process.

- Q: What are some alternative uses for a steel square outside of construction?

- Some alternative uses for a steel square outside of construction could include using it as a straight-edge or ruler for precise measurements in various crafts or DIY projects, as a guide for drawing or cutting straight lines in art or design work, or even as a makeshift level for checking the balance or alignment of objects. It can also serve as a sturdy and reliable tool for carpentry or woodworking tasks, such as checking right angles or marking precise angles for cutting or shaping materials. The versatility of a steel square makes it suitable for a wide range of applications beyond its primary use in construction.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Hot-rolled Square Steel Bar With Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords