5mm Stainless steel round bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering 5mm Stainless steel round bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

5mm Stainless steel round bar for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's 5mm Stainless steel round bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

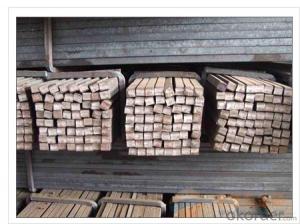

square steel billet

1.3SP, 5SP

2.terms of payment: L/C at sight

3.size: 120*120mm

4.length: 5.8~12m

square steel billet

Specifications

square steel billets

1)We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

M.S. Billets

CRS Billets

Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

The following are the sizes of Billets available with Shyam Steel Industries Ltd.:

100 X 100

120x120

150 X 150

Physical Properties:

Description

As per IS 2830

Shyam Billets

Bend (max.) 5 mm per meter >= 5 mm per meter

Carbon (max.) 3mm per meter >= 3 mm per meter

Length 3 mt - 13 mt 3 mt - 9 mt

Chemical Properties:

Ladle Analysis:

Designation

Carbon

Manganese

C15 0.12-0.18 0.30-0.60

C18 0.15-0.21 0.30-0.60

C20 0.17-0.23 0.30-0.60

C15 MMn 0.12-0.18 0.60-1.00

C18 MMn 0.15-0.21 0.60-1.00

C20 MMn 0.17-0.23 0.60-1.00

C15 HMn 0.12-0.18 1.00-1.50

C18 HMn 0.15-0.21 1.00-1.50

C20 HMn

0.17-0.23 1.00-1.50

Billets of different designations are manufactured in three different grades namely A, B, C having sulphur, phosphorous content (on ladle analysis) and carbon equivalent as follows:

Chemical Analysis:

Grade Sulphur Phosphorous Carbon Equivalent (CE)1

Max Max Max

A 0.05 0.05 0.42

B 0.045 0.045 0.41

C 0.04 0.04 0.39

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are some common applications for a steel square in fence construction?

- A steel square is a versatile tool commonly used in fence construction due to its accuracy and durability. Some common applications for a steel square in fence construction include: 1. Measuring and marking angles: A steel square is often used to accurately measure and mark angles during the installation of fence posts and rails. This ensures that the fence is properly aligned and level. 2. Checking for squareness: A steel square is an essential tool for checking if corners are perfectly square. This is crucial in fence construction to ensure that the fence panels are properly aligned and the overall structure is sturdy. 3. Determining cuts and lengths: A steel square can be used to measure and mark the correct length of fence rails, pickets, or panels. It helps in making accurate cuts and ensures that all components are uniform and fit together seamlessly. 4. Creating straight lines: Whether it's laying out the initial boundary or aligning fence components, a steel square can be used to create straight lines. By using the edge of the square as a guide, fence construction becomes more precise and visually appealing. 5. Checking for levelness: A steel square can also be used to check the levelness of fence posts and rails. By holding the square against the vertical surface, one can determine if the fence component is perfectly vertical or needs adjustment. 6. Squaring the gate frame: When constructing a gate, a steel square is invaluable in ensuring that the gate frame is perfectly square. This helps in preventing sagging and ensures smooth operation. Overall, a steel square is an indispensable tool in fence construction. It helps in achieving accurate measurements, levelness, and squareness, resulting in a professionally built and sturdy fence.

- Q: Can a steel square be used for deck railing layout and installation?

- Indeed, deck railing layout and installation can be accomplished utilizing a steel square. Known by various names such as framing square or carpenter's square, a steel square is a versatile instrument commonly employed in construction and woodworking to measure and denote right angles. Comprising a lengthy blade with markings along its length and a shorter tongue perpendicular to the blade, it takes the form of an L-shape. When it comes to deck railing layout and installation, a steel square proves invaluable in guaranteeing precise measurements and angles. It facilitates the alignment of posts and balusters, ensuring their accurate placement and uniform spacing. The measurements on the blade enable the marking of exact locations for the railing components, while the right angle formed by the blade and tongue allows for the verification of squareness and alignment. Moreover, a steel square serves as a useful guide for cutting and shaping the railing components. Its straight edge can be employed to draw straight lines or guide a circular saw or jigsaw, enabling meticulous cuts. Additionally, the tongue of the steel square can function as a guide for marking and drilling holes in the railing components. All in all, a steel square is an indispensable tool for deck railing layout and installation. Its precision and adaptability render it ideal for ensuring accurate measurements, angles, and alignment throughout the construction process.

- Q: Can a steel square be used for aligning fence posts?

- Yes, a steel square can be used for aligning fence posts.

- Q: How do you use a steel square to find the center of a round object?

- To use a steel square to find the center of a round object, you can follow these steps: 1. Place the round object on a flat surface, ensuring it is stable and doesn't wobble. 2. Take the steel square and position one of its edges against the side of the round object. 3. Make sure the steel square is perpendicular to the surface on which the round object is placed. 4. Hold the steel square firmly against the round object, ensuring it doesn't move or slide. 5. Look at the point where the other edge of the steel square intersects with the round object. This point is the approximate center of the round object. 6. To get a more accurate center, repeat the process from different angles, ensuring the steel square remains perpendicular to the surface each time. 7. Where the different lines intersect or meet each other is the precise center of the round object. By using a steel square in this manner, you can find the center of a round object with relative accuracy, which can be useful for various purposes such as marking, cutting, or drilling.

- Q: How do you read measurements on a steel square?

- To read measurements on a steel square, you first need to understand the different markings and graduations on the tool. A steel square typically consists of two arms, a longer one called the blade and a shorter one called the tongue, forming a 90-degree angle. On the blade, you will find a series of markings and numbers. These are usually in inches or centimeters and represent the length of the blade. The numbers start from 0 at the point where the blade and tongue meet and increase as you move towards the outer edge of the blade. The tongue of the steel square usually has a scale marked in inches or centimeters as well. This scale is used for taking measurements perpendicular to the edge of the blade. Similar to the blade, the numbers on the tongue start from 0 at the intersection and increase as you move towards the outer edge. To read measurements, align the desired point on the object you are measuring with the intersection of the blade and tongue. Then, observe the markings on the blade or tongue that correspond to the length or width you are measuring. For example, if you want to measure a length of 4 inches, locate the number 4 on either the blade or the tongue and note the corresponding point on the object. In addition to these basic measurements, steel squares may also have additional markings or features to aid in various tasks, such as finding angles or determining roof pitches. Familiarizing yourself with these additional markings can greatly enhance the versatility of the tool. Overall, reading measurements on a steel square involves understanding the markings and graduations on the blade and tongue, aligning the tool with the object being measured, and noting the corresponding numbers to determine the length or width.

- Q: Can a steel square be used for surveying work?

- Yes, a steel square can be used for certain surveying work, such as measuring right angles and checking the alignment of objects. However, it is not typically used as a primary tool for more precise surveying tasks, which usually require more specialized instruments such as total stations or GPS receivers.

- Q: What are some common uses of a steel square in welding?

- A steel square, a versatile tool widely used in welding, has numerous applications. Some common uses of a steel square in welding include the following: 1. Ensuring Right Angles: The primary purpose of a steel square is to guarantee that welded joints are perfectly right angles, thus maintaining the structural integrity of the workpiece. 2. Accurate Measurement and Marking: With graduated scales along their edges, steel squares enable welders to measure and mark different lengths precisely. This ensures precise dimensions for welded components. 3. Layout and Pattern Creation: Steel squares are often employed in layout work to mark and create patterns, templates, and cut lines on metal surfaces. They allow welders to create perpendicular lines, parallel lines, and scribe circles and arcs. 4. Alignment Checking: Steel squares are handy for checking the alignment of welded components. Whether it's ensuring perfect alignment before welding or checking the alignment of a welded joint, a steel square ensures accurate alignment. 5. Checking Flatness and Squareness: Welders frequently use steel squares to verify the flatness and squareness of welded surfaces. By placing the square against the surface or weld, they can determine if the area is flat or if the edges are square. 6. Setting Up Welding Tables: Steel squares are useful for aligning and squaring the framework of welding tables, ensuring a stable and level surface for welding operations. 7. Fabrication and Assembly: Steel squares are commonly employed in the fabrication and assembly of welded structures. They aid in positioning and aligning components during the welding process, resulting in accurate and strong welds. In conclusion, a steel square is an indispensable tool in a welder's arsenal, providing accuracy, precision, and reliability for various welding applications.

- Q: Can a steel square be used for checking the squareness of a miter saw blade?

- No, a steel square cannot be used for checking the squareness of a miter saw blade. While a steel square is a useful tool for measuring and checking right angles, it is not specifically designed to accurately gauge the squareness of a miter saw blade. Miter saws have their own mechanisms and adjustments to ensure the blade is perfectly perpendicular to the table. To check the squareness of a miter saw blade, it is recommended to use a specialized tool called a squareness gauge or a dedicated square specifically designed for miter saws. These tools are designed to provide precise measurements and angle checks, ensuring accurate and square cuts.

- Q: What are some common features of steel squares?

- Some common features of steel squares include: 1. Material: Steel squares are made from high-quality steel, which gives them durability and strength. 2. Shape: Steel squares are typically shaped like a right-angled triangle, with one long side and two shorter sides forming a 90-degree angle. 3. Accuracy: Steel squares are designed to provide accurate measurements and angles. The edges and corners are precisely machined to ensure precise and consistent results. 4. Markings: Steel squares often have markings along the edges, allowing users to measure and mark specific lengths or angles. 5. Graduations: Steel squares may have graduations or scales engraved or printed on the surfaces, enabling users to measure angles or distances more easily. 6. Versatility: Steel squares can be used for a variety of purposes, including measuring, marking, and checking right angles, as well as for determining and transferring angles. 7. Size and weight: Steel squares come in various sizes, typically ranging from small pocket-sized squares to larger squares used for more heavy-duty applications. The weight of a steel square depends on its size and thickness. 8. Corrosion resistance: Steel squares are often treated or coated to enhance their resistance to rust and corrosion, ensuring a longer lifespan. 9. Stability: Steel squares are designed to be stable and rigid, providing a reliable reference for accurate measurements and layout work. 10. Multi-functionality: Some steel squares may feature additional features, such as built-in spirit levels, scribing tools, or adjustable components, making them more versatile and convenient for specific applications.

- Q: How do you use a steel square to lay out a compound miter cut?

- To use a steel square to lay out a compound miter cut, you will need to follow a few steps. First, make sure you have a clear understanding of what a compound miter cut is. It is a cut that involves both an angle and a bevel. This means that the saw blade will need to be tilted and angled simultaneously to achieve the desired cut. Next, gather the necessary tools, including a steel square, a pencil, and a measuring tape. It is also helpful to have a miter saw or a compound miter saw for making the actual cut. Begin by determining the angle at which the cut needs to be made. This can be done by referring to the project plans or by measuring the angle on the workpiece directly. Once you have the angle, loosen the bevel adjustment on your miter saw and set it to the desired angle. Now, take the steel square and align one edge against the face of the workpiece. Make sure it is flush and straight, and then mark the desired cut line on the workpiece using a pencil. To find the bevel angle, position the steel square against the edge of the workpiece, aligning one leg against the face and the other leg against the edge. Again, ensure the square is flush and straight. Then, draw a line along the other leg of the square. The point where the two lines intersect represents the desired cut line for your compound miter cut. Double-check your measurements and angles before proceeding. Finally, carefully adjust the bevel angle on your miter saw to match the line you just drew. Secure the workpiece firmly in place and proceed with making the compound miter cut. Remember to always prioritize safety when using power tools. Wear appropriate protective gear, follow the manufacturer's instructions for your specific saw model, and take necessary precautions to avoid accidents.

Send your message to us

5mm Stainless steel round bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords