Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q195 or equivalent.

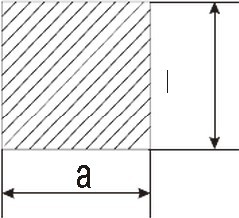

(The section of Square Steel)

Some details of Square Steel:

-List 1.The length of a side and the theoretical weight of Square Bar.

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

6 |

0.283 |

32 |

8.04 |

|

7 |

0.385 |

*33 |

8.55 |

|

8 |

0.502 |

34 |

9.07 |

|

9 |

0.636 |

*35 |

9.62 |

|

10 |

0.785 |

36 |

10.17 |

|

11 |

0.950 |

38 |

11.24 |

|

12 |

1.13 |

40 |

12.56 |

|

13 |

1.33 |

42 |

13.85 |

|

14 |

1.54 |

45 |

15.90 |

|

15 |

1.77 |

48 |

18.09 |

|

16 |

2.01 |

50 |

19.63 |

|

17 |

2.27 |

53 |

22.05 |

|

18 |

2.54 |

*55 |

23.6 |

|

19 |

2.82 |

56 |

24.61 |

|

20 |

3.14 |

*58 |

26.4 |

|

21 |

3.46 |

60 |

28.26 |

|

22 |

3.80 |

63 |

31.16 |

|

*23 |

4.15 |

*65 |

33.17 |

|

24 |

4.52 |

*68 |

36.3 |

|

25 |

4.91 |

70 |

38.49 |

|

26 |

5.30 |

75 |

44.16 |

|

*27 |

5.72 |

80 |

50.24 |

|

28 |

6.15 |

85 |

56.72 |

|

*29 |

6.60 |

90 |

63.59 |

|

30 |

7.06 |

95 |

70.85 |

|

*31 |

7.54 |

100 |

78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 2. The allowed tolerance of Square Steel:

|

Length of a side(mm) |

Allowed Tolerance | ||

|

Group1 |

Group2 |

Group3 | |

|

5.5~7 |

±0.20 |

±0.30 |

±0.40 |

|

7~20 |

±0.25 |

±0.35 |

±0.40 |

|

20~30 |

±0.30 |

±0.40 |

±0.50 |

|

30~50 |

±0.40 |

±0.50 |

±0.60 |

|

60~80 |

±0.60 |

±0.70 |

±0.80 |

|

80~110 |

±0.90 |

±1.0 |

±1.1 |

|

110~150 |

±1.2 |

±1.3 |

±1.1 |

|

150~190 |

―― |

―― |

±2.0 |

|

190~250 |

―― |

―― |

±2.5 |

Chemical Composition:

|

Standard |

Grade |

Element (%) | ||||

|

GB |

Q195 |

C |

Mn |

S |

P |

Si |

|

≤0.12 |

≤0.50 |

≤0.04 |

≤0.035 |

≤0.3 | ||

-Method of deoxidation: F, b, Z

Usage/Applications of Square Steel:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Square Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel:

- Q: How do you use a steel square for marking tenon and mortise joints?

- To use a steel square for marking tenon and mortise joints, you need to follow a few steps. Firstly, ensure you have a steel square with clear and accurate markings on it. Next, take the piece of wood you want to mark, and position it in the desired orientation for your joint. Place one end of the steel square against the edge of the wood, aligning it with the face or end of the wood depending on the type of joint you are making. Once the square is properly positioned, use a pencil or marking knife to trace along the edge of the square onto the wood. This will create a straight and precise line, allowing you to accurately cut or chisel out the mortise or tenon. For marking tenon joints, you will need to flip the wood and repeat the process on the other end. Make sure to align the square with the previously marked line to ensure consistency and accuracy. Additionally, the steel square can also be used to mark the depth of the mortise or tenon. By sliding the square along the length of the wood, you can mark the desired depth on the side of the wood using the square's markings. Overall, using a steel square for marking tenon and mortise joints is a simple yet effective method to ensure precise and clean joints. It helps to maintain the integrity of the joint and ensures a strong and durable connection between the two pieces of wood.

- Q: How do you use a steel square to determine the angle of a compound bevel and miter cut?

- To determine the angle of a compound bevel and miter cut using a steel square, you would first place the steel square against the edge of the material you are cutting. Then, align one leg of the square with the bevel cut line and the other leg with the miter cut line. By reading the measurement on the square where the two lines intersect, you can determine the angle of the compound bevel and miter cut.

- Q: How do you store a steel square to prevent rusting?

- To store a steel square and prevent it from rusting, you should follow a few simple steps: 1. Clean the steel square: Use a damp cloth or sponge to clean any dirt, debris, or grease from the steel square. Make sure to remove any moisture afterwards with a dry cloth to prevent water from causing rust. 2. Apply a protective coating: To provide an extra layer of protection against rust, you can apply a thin coat of oil or a rust-preventive spray. This helps to create a barrier between the steel and the air, preventing oxidation and rust formation. 3. Store in a dry location: Find a cool, dry place to store the steel square. Avoid areas with high humidity or moisture, such as basements or bathrooms. Moisture in the air can accelerate rusting, so it is essential to keep the storage environment dry. 4. Use a desiccant or moisture absorber: If you live in a particularly humid area or have concerns about moisture buildup, you can place a desiccant packet or a moisture absorber near the steel square. These products help to absorb any excess moisture in the air, reducing the risk of rust formation. 5. Avoid contact with other metals: When storing your steel square, make sure it does not come into contact with other metals, especially those prone to rusting. Different metals can create a galvanic reaction, accelerating rust formation. To prevent this, you can wrap the steel square in a soft cloth or store it in a protective case. By following these steps, you can effectively store a steel square and minimize the chances of rusting. Regularly inspect the square for any signs of rust or damage and reapply a protective coating if necessary.

- Q: Can a steel square be used for checking the squareness of a planer bed?

- No, a steel square cannot be used for checking the squareness of a planer bed.

- Q: How do you use a steel square to find the height of a chimney?

- To use a steel square to find the height of a chimney, you would need to measure the distance from the base of the chimney to a point where you can see the top of the chimney through the square's level. Then, by using the concept of similar triangles, you can calculate the height of the chimney using the known measurement and the height of the square.

- Q: What are some common applications for a steel square in flooring installations?

- A steel square, also known as a framing square or carpenter's square, is a versatile tool used in various aspects of flooring installations. Here are some common applications for a steel square in flooring projects: 1. Layout and marking: A steel square is essential for accurate layout and marking of straight lines and angles on flooring materials. It helps ensure precise measurements and alignment during the installation process. 2. Cutting and shaping: One of the primary uses of a steel square is for cutting and shaping flooring materials such as tiles, laminate, or vinyl. By using the square's straight edge and 90-degree angle, installers can make accurate cuts and achieve clean, straight lines. 3. Checking for squareness: A steel square is useful for checking if walls or corners are perfectly square before starting a flooring installation. This ensures that the flooring materials are laid down evenly and without any gaps or uneven edges. 4. Determining rise and run: In projects involving stairs or other elevated platforms, a steel square can be used to determine the rise and run of each step. By using the square's measurements and angles, installers can calculate the correct dimensions for a safe and comfortable staircase. 5. Spacing and alignment: When installing flooring materials like hardwood or laminate planks, a steel square can be used to maintain consistent spacing and alignment between each piece. This helps create a uniform appearance and prevents any gaps or unevenness in the flooring. 6. Marking cutouts: In cases where flooring materials need to be cut to fit around obstacles or fixtures such as pipes or cabinets, a steel square can be used to mark precise cutouts. It ensures that the cuts are made accurately, resulting in a seamless fit around these obstacles. Overall, a steel square is an invaluable tool in flooring installations due to its versatility, accuracy, and ability to perform various tasks ranging from layout and marking to cutting and shaping materials. Its precise measurements and angles help ensure a professional and well-finished flooring project.

- Q: Can a steel square be used for framing walls?

- Framing walls can be accomplished by utilizing a steel square. Known as a framing square or carpenter's square, this versatile tool is commonly employed in carpentry and framing endeavors. Typically crafted from steel, it possesses a 90-degree angle as well as a shorter 45-degree angle. When undertaking wall framing, a steel square proves invaluable in ensuring precise and square corners. It facilitates the measurement and marking of lumber, enables one to assess the squareness of walls, and guides the cutting and positioning of studs and other framing elements. By aligning the steel square's 90-degree angle with the wall's edges, the straightness and squareness of the framing are guaranteed. Furthermore, a steel square can be utilized for various other tasks related to wall framing, such as marking and cutting angles for roof rafters or stairs. Its durability and precision render it an indispensable tool for a multitude of framing duties, including wall construction.

- Q: What are some common measurements that can be taken with a steel square in metal fabrication?

- There are several common measurements that can be taken with a steel square in metal fabrication. Firstly, a steel square can be used to determine right angles. By aligning one side of the square with an edge or corner of a metal piece, the other sides can be used to check if the angle is perfectly 90 degrees. This is crucial in ensuring accurate fabrication and welding. Secondly, a steel square can be used to measure and mark straight lines. By aligning one edge of the square with a reference point on the metal, the other edges can be used as a guide to draw straight lines or make precise marks for cutting or drilling. Thirdly, a steel square can be used to measure and mark angles. By adjusting the square to the desired angle, the angles can be marked on the metal for cutting or bending purposes. This is especially useful for creating precise bends or mitre cuts. Additionally, a steel square can be used to check the flatness or levelness of a metal surface. By placing the square on the surface, any gaps or deviations from flatness can be detected. This is important for ensuring the quality and accuracy of the fabricated metal piece. In summary, a steel square is a versatile tool in metal fabrication that can be used for measuring right angles, straight lines, angles, and checking flatness or levelness. It plays a crucial role in ensuring precision and accuracy in metal fabrication processes.

- Q: Can a steel square be used for checking the squareness of a worktable?

- Yes, a steel square can be used to check the squareness of a worktable. A steel square is a measuring tool that consists of a long steel blade and a perpendicular handle. It is designed to ensure the accuracy of right angles, making it suitable for checking the squareness of a worktable. To use a steel square for this purpose, place the blade along one edge of the worktable and align the handle against the adjacent edge. If the table is perfectly square, the blade and handle of the square should be in perfect alignment. If they are not, it indicates that the worktable is not square and may need adjustments. By using a steel square to check the squareness of a worktable, you can ensure that your workpieces are accurately positioned and that your measurements and cuts are precise. It is a reliable and cost-effective tool for achieving squareness in woodworking or other tasks that require precise angles.

- Q: Can a steel square be used for marking out finger joints?

- Yes, a steel square can be used for marking out finger joints. A steel square is a versatile and precise tool commonly used in woodworking and carpentry. It has a 90-degree angle and a ruler along its edge, making it perfect for marking out straight lines and angles. When making finger joints, accuracy is crucial to ensure a proper fit. A steel square can be used to mark the lines and angles needed to create the joints, allowing for precise and clean cuts. However, it is important to note that finger joints require precise measurements and layout, so it is recommended to use a dedicated finger joint jig or a dado blade on a table saw for the best results.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords