Hot-rolled Square Steel Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50Tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

Specifications of Hot-rolled Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

-Chemical Composition:

|

Standard |

Grade |

Element (%) | ||||

|

C |

Mn |

S |

P |

Si | ||

|

GB |

Q195 |

0.06~0.12 |

0.25~0.50 |

≤0.050 |

≤0.045 |

≤0.30 |

|

GB |

Q235B |

0.12~0.20 |

0.30~0.70 |

≤0.045 |

≤0.045 |

≤0.30 |

-Mechanical Properties:

|

Mechanical Properties |

Grade |

Steel diameter(mm) | |||

|

≤16 |

16~40 |

40~60 |

60~100 | ||

|

Yield Point Δs/MPa |

Q195 |

≥195 |

≥185 |

- |

- |

|

Q235 |

235 |

225 |

215 |

205 | |

|

Tensile Strength |

Q195 |

315~390 | |||

|

Q235 |

375~500 | ||||

|

Elongation δ5% |

Q195 |

≥33 |

≥32 |

- |

- |

|

Q235 |

26 |

25 |

24 |

23 | |

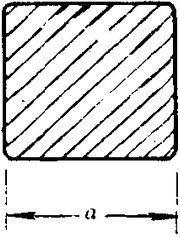

Measures of Hot-rolled Square Steel Bar (Big measures):

(Section of Hot-rolled Square Steel Bar)

-Length of a side and Theoretical weight of Square Bar (Big measures).

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

53 |

22.05 |

80 |

50.24 |

|

56 |

24.61 |

85 |

56.72 |

|

60 |

28.26 |

90 |

63.59 |

|

63 |

31.16 |

95 |

70.85 |

|

70 |

38.49 |

100 |

78.50 |

|

75 |

44.16 |

|

|

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

|

Steel |

Length of a side (mm) |

Length of steel (m) |

|

Normal steel |

< 25 |

4~10 |

|

> 25 |

3~9 | |

|

Steel of high quality |

All measure |

2~6 |

|

Tool steel >75 |

1~6 |

Usage/Applications of Hot-rolled Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

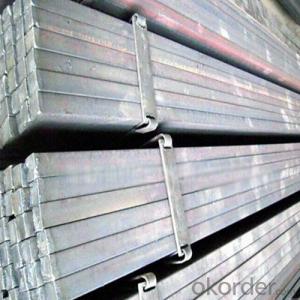

Packaging & Delivery of Hot-rolled Square Steel Bar:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons.

-Marks: We make tag marks and color marks for each bundle. The tag marks with white background and red company log will be tied up to each bundle. The information is usually including basic information of company and products like product name, specification, etc...and other information required by customers. As for color marks, we will paint both ends of each bundles to make sure that it will be more convenient for customers to distinguish theme from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

-The payment terms will be written in contraction detailedly.

Photos of Hot-rolled Square Steel Bar:

We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

- Q: Are there any specialty steel squares available for specific tasks?

- Yes, there are specialty steel squares available for specific tasks. These squares are designed with unique features and measurements to cater to specific needs in various industries. Some examples include carpenter's squares for woodworking, roofer's squares for roofing tasks, and machinist's squares for precision measurements in metalworking. These specialty steel squares offer enhanced accuracy and functionality to ensure precise and efficient results in their respective tasks.

- Q: Can a steel square be used for automotive repairs?

- Yes, a steel square can be used for automotive repairs. It is a versatile tool that can be utilized for measuring and checking angles, ensuring accuracy in repairs and alignments.

- Q: How do you use a steel square to find angles for scribe cuts?

- To use a steel square to find angles for scribe cuts, you need to follow a few steps. Firstly, ensure that your steel square is clean and in good condition. This will ensure accurate measurements. Next, place the square against the edge of the material you want to make the scribe cut on, with one side of the square parallel to the edge. Then, adjust the position of the square until the other side of the square aligns with the desired angle for the scribe cut. Once the square is in position, use a pencil or scribe to mark a line along the edge of the square. After marking the line, remove the square and double-check the line you marked to ensure it is straight and accurate. Finally, you can proceed to make the scribe cut along the marked line using a suitable cutting tool. Using a steel square in this way allows you to easily find and transfer angles for scribe cuts, ensuring precise and clean results.

- Q: Can a steel square be used for checking the squareness of a jointer guard?

- No, a steel square cannot be used for checking the squareness of a jointer guard. A steel square is primarily used for checking the squareness of edges and corners, and it may not provide accurate results when used for checking the squareness of a jointer guard. Jointer guards have specific angles and dimensions that need to be aligned properly for safety and optimal performance. It is recommended to use the appropriate tools and methods recommended by the manufacturer or consult a professional to ensure the correct squareness of a jointer guard.

- Q: Can a steel square be used for marking and scribing?

- Certainly, a steel square is an excellent tool for marking and scribing purposes. Known as combination squares, these versatile tools are widely used in woodworking, metalworking, and construction. Typically, they consist of a ruler-like blade equipped with a sliding head that can be securely locked at different angles. The steel blade of the square is precisely marked with measurements, enabling accurate marking and layout of lines on a workpiece. These markings serve various purposes, including cutting, drilling, and joining pieces together. Furthermore, the sliding head can be adjusted to different angles, making it valuable for creating angled lines or determining squareness. In addition to marking, a steel square can also be utilized for scribing. Scribing involves drawing a line on a surface that follows the contour or edge of another object. This proves particularly useful when fitting pieces together or transferring measurements from one surface to another. The durability and rigidity of a steel square render it an ideal tool for precise marking and scribing tasks. Its steel construction ensures long-lasting accuracy and reliability, even in demanding work environments. Therefore, a steel square is an indispensable tool for craftsmen and DIY enthusiasts seeking to achieve precise and professional outcomes.

- Q: Can a steel square be used for checking the alignment of beams?

- Yes, a steel square can be used for checking the alignment of beams. A steel square is a versatile tool commonly used by carpenters and builders for various measurements and alignments. It consists of a long metal blade with a perpendicular handle. When used for checking the alignment of beams, the square's long blade can be placed along the length of the beam to ensure that it is straight and not warped. The perpendicular handle can be used to verify if the beam is perfectly vertical or horizontal. By placing the square against the beam's edges or surfaces, any deviations from the desired alignment can be easily identified. Therefore, a steel square is a reliable and efficient tool for checking the alignment of beams in construction projects.

- Q: Can a steel square be used for measuring the pitch of a roof?

- Yes, a steel square can be used for measuring the pitch of a roof. The steel square has markings and angles that can help determine the slope or angle of the roof, making it a useful tool for measuring pitch.

- Q: How do you care for and maintain a steel square?

- In order to care for and maintain a steel square, it is important to follow several crucial steps. First and foremost, keeping the steel square clean and free from debris or dirt is crucial. After each use, it is recommended to wipe it down with a clean cloth to eliminate any dust or grime. This practice will prevent any accumulation and guarantee that the square remains in good condition. Secondly, protecting the steel square from rust is essential. Steel is prone to rusting, particularly when exposed to moisture or humidity. To prevent this, it is necessary to store the square in a dry and well-ventilated area. If the square does become wet, it should be thoroughly dried before storing it to prevent any lingering moisture on the surface. Moreover, it is advisable to consider applying a thin coat of oil to the steel square. This can be achieved by using a clean cloth and gently rubbing a small amount of oil onto the surface. The oil acts as a protective barrier against moisture and assists in preventing rust. Nevertheless, it is important to wipe off any excess oil to avoid attracting dust or dirt. Furthermore, regularly checking the accuracy of the square is crucial. Over time, the square may become misaligned or lose its accuracy. To ensure its precision, it is recommended to compare the square against a known straight edge or use a squareness tester. If any discrepancies are found, adjustments may be necessary. Most steel squares are equipped with adjustment screws or bolts that can be utilized to correct any misalignment. Lastly, handling the steel square with care is of utmost importance. Avoiding dropping or mishandling it is crucial to prevent any damage. When not in use, it is wise to store it in a protective case or wrap it in a soft cloth to prevent accidental harm. By following these care and maintenance guidelines, you can guarantee that your steel square remains in good condition, accurate, and ready for use whenever necessary.

- Q: Can a steel square be used for plumbing pipe layout?

- Certainly! The steel square is capable of assisting in plumbing pipe layout. Known as a framing square or carpenter's square, this versatile tool can be utilized for various construction and layout tasks. In terms of plumbing pipe layout, the steel square proves beneficial in determining angles, measuring and designating straight lines, and guaranteeing precise cuts and connections. Its functionality extends to measuring and marking the necessary angles for pipe bends, as well as inspecting the overall plumbing layout for squareness and alignment. Moreover, the steel square's robust and enduring nature renders it suitable for use in plumbing applications that demand utmost precision and accuracy.

- Q: How do you use a steel square to measure the width of a door jamb?

- To use a steel square to measure the width of a door jamb, follow these steps: 1. Ensure you have a steel square that has a long blade and a shorter tongue perpendicular to each other. This is often called a framing square or carpenter's square. 2. Start by holding the steel square against the inside edge of the door jamb, with the long blade touching the floor and the tongue facing towards the door opening. 3. Slide the square until the long blade is flush against one side of the door jamb. Make sure the square is held firmly and remains level. 4. Look at the measurement markings on the long blade of the square. The numbers on the blade represent inches or centimeters. Identify the mark that aligns with the opposite side of the door jamb. This will give you the width measurement of the door jamb. 5. Take note of the measurement and repeat the process on the other side of the door jamb to ensure accuracy. If the door jamb is not perfectly square, take multiple measurements at different points along the jamb to get an average width. By following these steps, you can effectively use a steel square to measure the width of a door jamb. It is important to have a steady hand and ensure the square remains level for accurate measurements.

1. Manufacturer Overview

| Location | Renqiu, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Mid East; Southeast Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 70,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Hot-rolled Square Steel Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50Tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords