Steel Square Shaped Straight Bars with Sizes 5MM to 100MM High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Square Shaped Straight Bars description:

Steel square shaped straight bar is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, steel square shaped straight bar is still in the form of a metal bar or rectangle. Small sizes of steel square shaped straight bars are used in ship building.

2. Main Features of Steel Square Shaped Straight Bars:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

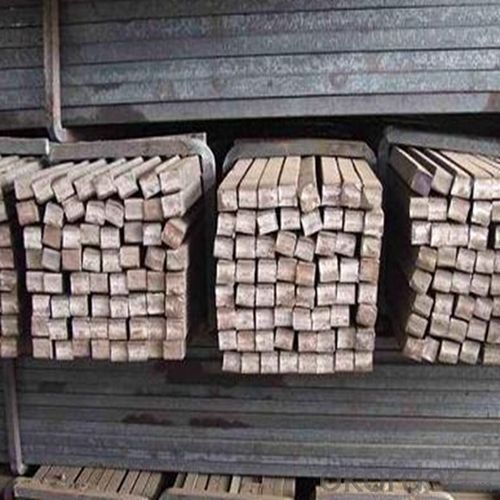

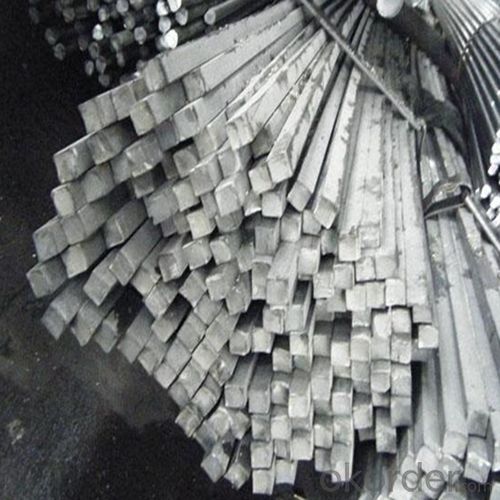

3. Steel Square Shaped Straight Bars Images:

4. Steel Square Shaped Straight Bars Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can a steel square be used for checking the alignment of a bandsaw table?

- Indeed, the alignment of a bandsaw table can be assessed using a steel square. This versatile tool enables the measurement and evaluation of the squareness and alignment of different surfaces and objects. In the context of a bandsaw table, one can position a steel square against the table surface and the blade, visually inspecting whether the blade runs parallel to the table or if it is tilted. This examination is crucial for bandsaw operation, as an improperly aligned blade can result in imprecise cuts and potential safety risks. By utilizing a steel square, one can promptly and effortlessly determine if any adjustments are necessary to guarantee the appropriate alignment of the bandsaw table.

- Q: What are the different types of steel squares?

- Various applications utilize several types of steel squares. One commonly used square is the framing square, also known as a carpenter's square. Carpenters and construction workers employ this type of square to ensure precise right angles when framing walls, roofs, and other structures. It consists of a long arm and a shorter arm meeting at a 90-degree angle. Another steel square is the combination square, which also has a 90-degree angle like the framing square. However, it possesses an adjustable ruler attached to one of the arms. This feature allows the combination square to measure and mark angles other than 90 degrees, as well as straight lines and depths. It is widely used in woodworking and metalworking. For woodworking purposes, the try square comes into play. While resembling a framing square, it is smaller and has a shorter arm. Try squares are primarily employed to mark and verify right angles when working with smaller wood pieces, such as joinery or cabinetmaking projects. Machinist squares are precision tools utilized in metalworking and machining. Typically made of hardened steel, they possess a high degree of accuracy. Machinist squares are utilized to check the squareness and alignment of machine parts, as well as for layout and marking in metalworking processes. Specialized steel squares, such as rafter squares or roofing squares, are utilized by carpenters and roofers to calculate and mark angles for roof rafters and other roofing elements. These squares often possess additional markings and features specific to roofing applications. In conclusion, the types of steel squares include framing squares, combination squares, try squares, machinist squares, and specialized squares for roofing. Each square serves its own specific purpose and finds application in various industries.

- Q: Can a steel square be used for measuring and marking compound bevel, miter, and crown molding cuts?

- Certainly! A steel square is capable of measuring and marking compound bevel, miter, and crown molding cuts. This versatile tool serves various carpentry purposes, such as measuring and marking angles. Carpenters can accurately ascertain the angles and dimensions required for compound bevel, miter, and crown molding cuts by utilizing the square's distinct markings and measurements. Moreover, the steel square's robust and durable nature guarantees its ability to endure the pressure and precision demanded by these cuts. Nevertheless, it is crucial to consider that the utilization of a steel square for such cuts may necessitate supplementary calculations and adjustments to accommodate the compound angles involved.

- Q: Can a steel square be used for checking the plumbness of walls?

- Checking the plumbness of walls can be done using a steel square. This versatile tool is employed in carpentry and construction for a range of measurement and marking tasks. Among its uses is the assessment of wall plumbness or vertical alignment. By positioning the steel square against the wall, specifically at the corner, and utilizing a level to confirm its perfect verticality, one can ascertain if the wall is plumb or if it is leaning inward or outward. This technique offers a fast and precise means of evaluating wall verticality and is commonly employed by industry professionals.

- Q: Can a steel square be used for marking and cutting wood?

- Yes, a steel square can be used for marking and cutting wood. It is a versatile tool that is commonly used in woodworking to ensure accurate measurements, mark straight lines, and create precise angles. The steel square's sturdy construction makes it suitable for marking and guiding saw cuts on wood.

- Q: What are the different types of steel squares available?

- There are several different types of steel squares available, including the try square, combination square, framing square, and speed square. Each type has its own unique features and is designed for specific applications in woodworking, metalworking, or construction.

- Q: What is the history of steel squares?

- Steel squares have a long and rich history, dating back to ancient times. The concept of a square tool for measuring right angles can be traced back to the ancient Egyptians and Mesopotamians. However, it was during the 18th and 19th centuries that steel squares as we know them today began to emerge. These squares were initially made from cast iron and gradually evolved into being made from steel, which provided increased durability and accuracy. They became an essential tool for carpenters, masons, and other craftsmen, enabling them to measure and mark right angles with precision. Over the years, steel squares have undergone technological advancements, such as incorporating additional measurements and features like protractors and scales. They continue to be widely used in various industries for layout work, framing, and woodworking. In summary, the history of steel squares is one of evolution and refinement, starting from ancient origins to becoming an indispensable tool for professionals across different trades.

- Q: How do you use a steel square to find angles for scribe cuts?

- To use a steel square to find angles for scribe cuts, you would start by placing the square against the material you want to cut. Align one side of the square with the edge of the material. Then, rotate the square until the desired angle is achieved, making sure the other side of the square remains in contact with the material. Once the square is properly positioned, you can scribe along the edge of the square to mark the cut line.

- Q: Can a steel square be used for measuring the depth of a well?

- No, a steel square cannot be used for measuring the depth of a well. A steel square, also known as a try square or a framing square, is a tool typically used in carpentry and woodworking to measure and mark right angles. It consists of a long steel blade with a handle at one end, forming an "L" shape. Measuring the depth of a well requires a different type of tool known as a well depth indicator or well sounder. This tool usually consists of a long, narrow metal tape or cable with markings indicating depth. It is specifically designed to measure the depth of water in a well or borehole. Using a steel square to measure the depth of a well would not provide accurate or reliable results. It is essential to use the appropriate tools designed specifically for well depth measurement to ensure accurate readings and proper well management.

- Q: Can a steel square be used for checking the squareness of a table saw sled?

- Yes, a steel square can be used for checking the squareness of a table saw sled. A steel square is a widely used tool for measuring and checking angles and can be relied upon for accuracy. To check the squareness of a table saw sled, place the steel square against the fence of the sled, ensuring that it is flush against the fence. Next, position the sled against the table saw blade and check if the square is perpendicular to the blade. If the square aligns perfectly with the blade, then the sled is square. If there is any gap or misalignment, adjustments can be made to the sled to ensure it is squared properly.

Send your message to us

Steel Square Shaped Straight Bars with Sizes 5MM to 100MM High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords