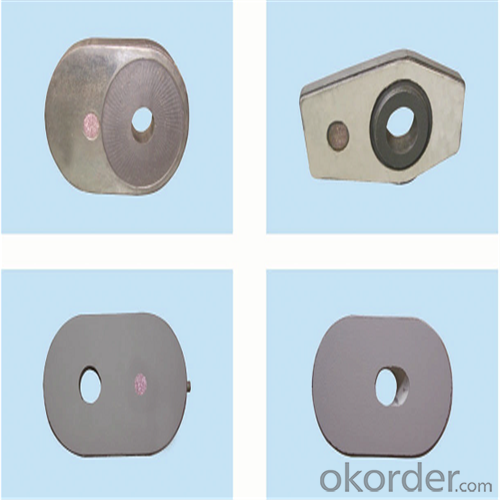

Monolithic Refractories High Performance Ladle Sliding Gate for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

About us

Sample is on your request.

Welcome to visit our factory~

- Q: How do monolithic refractories resist abrasion in the iron and steel industry?

- Monolithic refractories, with their unique composition and properties, are specifically designed for the iron and steel industry to resist abrasion. Made from a single homogeneous material, they exhibit exceptional strength and durability when subjected to continuous abrasion. The high density of monolithic refractories is one of the key factors contributing to their abrasion resistance. These refractories are manufactured with tightly packed particles, resulting in a solid and compact structure. This density minimizes wear and tear caused by the constant movement of materials like iron and steel. Furthermore, monolithic refractories often contain high levels of alumina, known for its excellent resistance to abrasion. Alumina is a highly refractory material that can withstand high temperatures and mechanical stress without deteriorating. Its presence in monolithic refractories creates a protective layer that resists abrasion caused by the movement and impact of iron and steel particles. In addition, monolithic refractories can be designed with specific additives and binders that further enhance their resistance to abrasion. These additives may include silicon carbide, mullite, or zirconia, which are renowned for their superior mechanical strength and ability to withstand wear. The binders used in the manufacturing process also contribute to the refractory's integrity and its ability to resist abrasion by providing a cohesive structure. In conclusion, the combination of high density, alumina content, specialized additives, and binders makes monolithic refractories highly resistant to abrasion in the iron and steel industry. They can withstand the harsh conditions and constant movement of materials, ensuring long-lasting performance and efficiency in various applications within the industry.

- Q: What are the common failure mechanisms of monolithic refractories in the iron and steel industry?

- Common failure mechanisms observed in monolithic refractories within the iron and steel industry include: 1. Thermal spalling: Monolithic refractories endure extreme temperature variations during the iron and steel production process. These rapid changes in temperature can cause the refractory material to expand and contract, resulting in thermal stress and eventual spalling. This failure mechanism is particularly prevalent in areas where the refractory is exposed to elevated temperatures, such as the hot face of a furnace. 2. Chemical attack: The iron and steel production process involves the utilization of various chemicals and molten metal, which can react with the refractory material over time. Chemical attack can lead to the deterioration of the refractory, resulting in cracks, erosion, and eventual failure. Slag, alkalis, sulfur, and other impurities present in the production environment are commonly responsible for this type of damage. 3. Abrasion: The movement of materials, such as iron ore, coke, and fluxes, can cause abrasion on the refractory lining. This mechanical wear and tear weaken the refractory material, eventually leading to failure. Areas experiencing high material flow rates or turbulence, such as tapholes or launder systems, are particularly prone to abrasion. 4. Corrosion: Monolithic refractories can be susceptible to corrosion caused by gases, liquids, and solids found in the iron and steel production environment. Corrosion occurs due to the presence of oxygen, water vapor, and various chemical compounds, such as carbon monoxide and sulfur compounds. It results in the formation of corrosive products, such as oxides or sulfides, which degrade the refractory material over time. 5. Mechanical stress: Monolithic refractories may undergo mechanical stress due to factors like thermal expansion and contraction, vibration, or mechanical impact. Excessive mechanical stress can lead to the development of cracks or fractures in the refractory lining, compromising its integrity and resulting in failure. To mitigate these failure mechanisms, it is crucial to select appropriate refractory materials, conduct regular inspections, and perform necessary maintenance. Furthermore, designing refractory linings that consider specific operational conditions and employing appropriate installation techniques can enhance their performance and lifespan within the iron and steel industry.

- Q: How do monolithic refractories resist erosion from molten metals and slags?

- Monolithic refractories resist erosion from molten metals and slags through several mechanisms. Firstly, they have a high melting point, which allows them to withstand the high temperatures of molten metals and slags without any significant degradation. Secondly, they have a dense and compact structure, which reduces the penetration of molten metals and slags into their surface. Additionally, monolithic refractories often contain additives such as antioxidants or slag resistance agents, which further enhance their resistance to erosion.

- Q: How are monolithic refractories recycled or disposed of at the end of their lifespan?

- Monolithic refractories, widely utilized in high-temperature industrial applications, offer various means of recycling or disposal once their lifespan concludes. The preferred approach depends on the specific monolithic refractory type and its composition. Reclamation stands as a common method for recycling monolithic refractories. This process entails collecting used refractory materials and subjecting them to processing to eliminate any impurities or contaminants. The resultant reclaimed refractory material can then be crushed, ground, or milled into a fine powder suitable for utilization as a raw material in manufacturing new refractories. Thermal treatment represents an alternative means of recycling monolithic refractories. This method involves exposing the used refractory material to high temperatures within a controlled environment, such as a kiln or furnace. The heat effectively breaks down the refractory material, eliminating any binders or impurities. The resulting material can then be reused as a raw material or integrated into other applications, such as construction aggregates. When recycling is not feasible, specialized facilities designed for handling and treating hazardous waste offer a disposal avenue for monolithic refractories. These facilities ensure the proper containment and treatment of the refractory material, minimizing any potential environmental impact. This disposal method is typically reserved for refractories containing hazardous substances or those that cannot be recycled due to their composition. It is important to emphasize that the appropriate disposal or recycling method for monolithic refractories must adhere to local regulations and guidelines. These regulations aim to ensure the safe handling, treatment, and disposal of these materials, taking into account their potential environmental and health effects. Therefore, industries and businesses must collaborate closely with waste management professionals and adhere to the appropriate procedures to responsibly manage monolithic refractories at the end of their lifespan.

- Q: How do monolithic refractories perform in rotary hearth furnace applications?

- Monolithic refractories perform exceptionally well in rotary hearth furnace applications due to their ability to withstand high temperatures, thermal shock, and mechanical stresses. Their unique properties and composition make them highly resistant to chemical attacks and erosion, ensuring long-lasting and reliable performance in these demanding environments. Additionally, their easy installation and repair process make them a preferred choice for rotary hearth furnace applications.

- Q: How do monolithic refractories impact the overall productivity of iron and steel operations?

- The overall productivity of iron and steel operations is greatly enhanced by monolithic refractories. These refractories are specifically designed to withstand extreme temperatures, chemical reactions, and mechanical stress that occur during production. One important way that monolithic refractories impact productivity is by reducing downtime and increasing operational efficiency. These refractories have high thermal conductivity and are resistant to thermal shock, allowing them to maintain stable temperatures within the furnace. This prevents sudden temperature fluctuations that can lead to equipment failure and production delays. As a result, the production process can continue uninterrupted, leading to increased productivity. Furthermore, monolithic refractories offer superior corrosion resistance, preventing the erosion and degradation of furnace linings. This resistance to chemical attacks from molten metals and slag helps prolong the lifespan of the refractory lining, reducing the need for repairs and replacements. This leads to less downtime and higher productivity for iron and steel operations. Additionally, monolithic refractories enable faster installation and repair processes compared to traditional brick refractories. They have a fluid-like consistency that makes application and shaping easy, resulting in shorter installation and curing times. This quick turnaround time minimizes production interruptions during repairs or maintenance, further increasing overall productivity. Moreover, the use of monolithic refractories can optimize energy consumption in iron and steel operations. Their excellent insulation properties help retain heat within the furnace, reducing heat loss and energy waste. This improves energy efficiency and leads to cost savings, ultimately contributing to increased productivity and profitability. In conclusion, monolithic refractories have a significant impact on the productivity of iron and steel operations. Their ability to withstand extreme conditions, reduce downtime, resist corrosion, facilitate quick repairs, and optimize energy consumption all contribute to improved efficiency and productivity in the industry.

- Q: How do monolithic refractories handle thermal expansion and contraction?

- Monolithic refractories handle thermal expansion and contraction by their ability to withstand high temperatures and adapt to changes in size without cracking or breaking. They are designed to have low thermal conductivity, which helps to minimize stress caused by thermal cycling. Additionally, they are often composed of materials with high refractoriness and high thermal shock resistance, allowing them to expand and contract with minimal damage.

- Q: How do monolithic refractories mitigate heat loss in iron and steel operations?

- Monolithic refractories are highly effective in mitigating heat loss in iron and steel operations due to their unique properties and composition. These refractories are made from a single, continuous material, making them resistant to cracks and gaps that could allow heat to escape. One key advantage of monolithic refractories is their excellent thermal conductivity and insulation properties. They have a low thermal conductivity, which means they can effectively restrict the transfer of heat from the hot areas to the cooler surroundings. This insulation property helps maintain high temperatures within the iron and steel operations, reducing heat loss to the environment. Another factor that contributes to the heat loss mitigation is the ability of monolithic refractories to form a tight seal with the metal structures they are applied to. They adhere well to the surfaces and fill in any gaps or irregularities, creating a solid barrier against heat loss. This seal minimizes the possibility of heat escaping, ensuring that the energy generated within the operations is effectively utilized. Furthermore, monolithic refractories have high resistance to thermal shock. In the iron and steel industry, extreme temperature fluctuations are common, which can lead to material deterioration and cracks. Monolithic refractories, with their high thermal shock resistance, are able to withstand these rapid temperature changes without compromising their structural integrity. This ensures the longevity and effectiveness of the refractories in mitigating heat loss. Overall, monolithic refractories play a crucial role in mitigating heat loss in iron and steel operations by providing excellent insulation, forming a tight seal, and withstanding thermal shock. These properties allow the refractories to maintain high temperatures within the operations, optimize energy utilization, and enhance the overall efficiency of the processes.

- Q: What are the key properties and characteristics of monolithic refractories?

- Monolithic refractories, renowned for their ability to be shaped or installed in a single piece without joints, are a type of refractory material. They find their utility in high-temperature applications where traditional brick or tile refractories may not suffice. One noteworthy attribute of monolithic refractories lies in their superior thermal stability. They can withstand extreme temperatures without significant expansion or contraction, making them an ideal choice for furnaces, kilns, and other heat-intensive environments. This quality ensures the maintenance of their structural integrity and grants long-lasting performance. Another significant characteristic of monolithic refractories is their high resistance to thermal shock. They can endure abrupt temperature changes without cracking or spalling, a crucial aspect when the refractory material is exposed to alternating hot and cold conditions. The resistance to thermal shock ensures the refractory lining's longevity, reducing the need for frequent repairs or replacements. Monolithic refractories also demonstrate commendable mechanical strength, enabling them to withstand the mechanical stresses and loads imposed on them during usage. They possess excellent load-bearing capacity, resisting abrasion, erosion, and impact, making them suitable for applications where the refractory material faces mechanical wear or impact. Moreover, monolithic refractories offer the advantage of easy installation and repair. Unlike traditional refractories that necessitate skilled labor and time-consuming bricklaying techniques, monolithic refractories can be cast, gunned, or sprayed into place. This effortless installation expedites turnaround times and minimizes downtime during repairs or maintenance. Lastly, monolithic refractories exhibit commendable chemical resistance to various corrosive agents, such as acids, alkalis, and molten metals. This property renders them suitable for use in industries where the refractory material encounters aggressive chemical environments, including the steel, petrochemical, and glass industries. In summary, monolithic refractories possess excellent thermal stability, high resistance to thermal shock, good mechanical strength, effortless installation and repair, and commendable chemical resistance. These properties establish them as the preferred choice in high-temperature applications where durability, reliability, and performance are of utmost importance.

- Q: How do monolithic refractories improve the performance of ladles and tundishes?

- Monolithic refractories improve the performance of ladles and tundishes by providing superior thermal insulation, high mechanical strength, and resistance to chemical attacks and thermal shocks. These qualities enhance the overall durability and longevity of the ladles and tundishes, reducing the need for frequent repairs or replacements. Additionally, monolithic refractories offer better flow properties, facilitating smooth and efficient pouring of molten metal, while minimizing the risk of slag or metal infiltration. Overall, the use of monolithic refractories improves the efficiency, productivity, and cost-effectiveness of ladles and tundishes in various industrial applications.

Send your message to us

Monolithic Refractories High Performance Ladle Sliding Gate for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords