Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

Scaffolding Screw Jack Formwork Scaffolding China Low Price

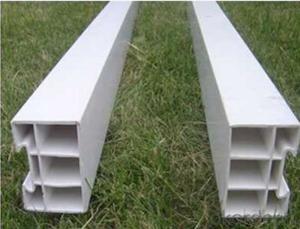

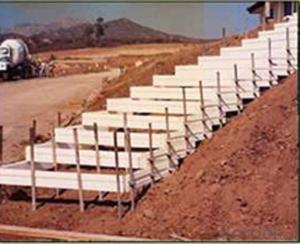

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

Scaffolding Screw Jack Formwork Scaffolding China Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

- Q: Can steel frame formwork be used for both reinforced and non-reinforced concrete structures?

- Steel frame formwork is suitable for both reinforced and non-reinforced concrete structures. This versatile system can be easily adjusted and adapted to meet the requirements of different construction projects. It offers a robust and rigid framework for pouring concrete, ensuring the stability and integrity of the structure. Whether there is reinforcement or not, the steel frame formwork can be designed and installed to provide the necessary support and shape for the concrete during construction. It is widely utilized in the construction industry for various projects, such as buildings, bridges, tunnels, and other concrete structures, regardless of their reinforcement status.

- Q: What are the different sizes and dimensions available for steel frame formwork?

- Steel frame formwork is available in various sizes and dimensions to cater to different construction requirements. The specific sizes and dimensions may vary based on the manufacturer and the specific project, but generally, they can be categorized into the following types: 1. Standard Panels: These are the most commonly used steel frame formwork panels and come in standard sizes such as 1.2m x 2.4m or 1.5m x 3.0m. The thickness of these panels typically ranges from 12mm to 18mm, depending on the load-bearing capacity required. 2. Large Panels: For larger structures or projects that require greater strength and stability, larger steel frame formwork panels are available. These panels can be as large as 2.0m x 3.0m or even bigger, with increased thicknesses ranging from 18mm to 25mm. 3. Adjustable Panels: To accommodate varying dimensions and complexities of construction projects, adjustable steel frame formwork panels are also available. These panels can be adjusted to different sizes and dimensions, allowing for greater flexibility and adaptability on the construction site. 4. Customizable Panels: Some manufacturers offer customizable steel frame formwork panels, which can be tailored to meet specific project requirements. These panels can be manufactured in non-standard sizes and dimensions to fit unique construction needs. In addition to the panel sizes, steel frame formwork systems may also include various accessories such as adjustable props, connectors, and clamps, which further enhance the versatility and functionality of the formwork. It is important to note that the availability of different sizes and dimensions may vary depending on the manufacturer and the region. Therefore, it is essential to consult with the specific supplier or manufacturer to determine the exact sizes and dimensions available for steel frame formwork.

- Q: Can steel frame formwork be used for the construction of hospitality facilities?

- Indeed, hospitality facilities can be constructed using steel frame formwork. This versatile and long-lasting construction method is commonly employed in a variety of building projects, including those in the hospitality sector. Steel frame formwork consists of easily assembled and disassembled steel frames, adding flexibility to the construction process. The use of steel frame formwork offers numerous benefits for the construction of hospitality facilities. Firstly, steel is a robust and enduring material capable of withstanding the heavy loads and stresses typically encountered in such establishments. This ensures the stability and safety of the structure. Moreover, steel frame formwork enables efficient construction processes. The frames can be effortlessly adjusted and reused, resulting in reduced construction time and costs. This advantage is particularly valuable in hospitality projects, where meeting project deadlines often depends on swift construction. Furthermore, steel frame formwork facilitates a high level of accuracy and precision during construction. The frames are meticulously designed to be straight and level, guaranteeing that the resulting structure is of superior quality and adheres to design specifications. This aspect is crucial in hospitality facilities, as aesthetics and attention to detail are paramount in creating an inviting and visually appealing environment for guests. To conclude, steel frame formwork is indeed a suitable choice for the construction of hospitality facilities. Its strength, durability, efficiency, and precision provide a solid foundation for the creation of welcoming and well-constructed establishments in the hospitality industry.

- Q: Can steel frame formwork be easily integrated with building automation systems?

- Yes, steel frame formwork can be easily integrated with building automation systems. The rigid and durable nature of steel frame formwork allows for seamless integration with automation systems, enabling efficient control and management of the formwork process.

- Q: How does steel frame formwork contribute to the overall sustainability of a construction project?

- There are several ways in which the use of steel frame formwork contributes to the overall sustainability of a construction project. To begin with, steel is an extremely durable material that can withstand the demands of construction. This durability ensures that the formwork system will last a long time, reducing the need for frequent replacements. As a result, there is a decrease in waste generation and resource consumption. Furthermore, unlike traditional timber formwork that is often discarded after one use, steel frame formwork can be dismantled and reused multiple times. This significantly reduces material waste and minimizes the environmental impact of the construction process. Moreover, steel is a recyclable material. Once it reaches the end of its useful life as formwork, steel frames can be recycled and used to create new steel products. This helps to reduce the demand for new materials and conserve natural resources. In addition, steel frame formwork offers flexibility in design and construction. Its modular nature allows for easy customization and adjustment, minimizing the need for excessive material cutting and reducing construction waste. This adaptability also ensures efficient resource use and decreases the overall environmental footprint of the project. Furthermore, steel frame formwork enables faster construction compared to traditional formwork systems. This results in reduced energy consumption, lower carbon emissions, and a smaller environmental impact. In conclusion, the use of steel frame formwork promotes sustainability in construction projects by promoting durability, reusability, recyclability, flexibility, and efficiency. By incorporating steel frame formwork, construction projects can minimize waste, conserve resources, reduce carbon emissions, and create more sustainable built environments.

- Q: Can steel frame formwork be used for historical and heritage restoration projects?

- Indeed, historical and heritage restoration projects can utilize steel frame formwork. By offering a robust and long-lasting framework for concrete pouring, steel frame formwork permits the precise execution of intricate designs and details. This quality renders it suitable for restoration endeavors that demand accurate reconstruction or repair of historical edifices while preserving their original appearance and structural soundness. Moreover, steel frame formwork can be tailored to meet specific project requirements, ensuring its compatibility with the unique challenges associated with the restoration of historical and heritage buildings. Its adaptability and strength establish it as a practical choice for such projects, empowering craftsmen to meticulously restore and safeguard the architectural heritage of yesteryears.

- Q: What are the principles of the layout and spacing of steel structure engineering framework

- Frame column layout, to meet the requirements of the production process, to meet the construction requirements, the structure of plane stress is reasonable and convenient for construction of four aspects. The intersection of the pillars in building on the vertical and horizontal axis, in order to reduce the influence of the building use function column. The column is also associated with the beam span, column size can obtain a larger space, but will increase the beam column section size, should be combined with the construction needs and considering the cost of the structure.

- Q: How does steel frame formwork handle the placement of reinforcement couplers and splices within the concrete structure?

- When it comes to handling the placement of reinforcement couplers and splices within concrete structures, steel frame formwork proves to be a versatile and efficient method. It offers numerous benefits in this regard. To begin with, the flexibility of steel frame formwork allows for easy accommodation and adjustment of reinforcement couplers and splices. The formwork system comprises modular panels that can be readily configured to meet the specific requirements of the reinforcement layout. This ensures precise placement of the couplers and splices within the concrete structure. Moreover, steel frame formwork provides ample space and accessibility for the installation of these components. The design of the formwork panels allows for clear access to the reinforcement bars, enabling workers to easily install the couplers and splices at the designated positions. This accessibility is crucial in integrating the reinforcement system effectively into the concrete structure, thereby enhancing its strength and durability. Additionally, steel frame formwork offers stability and support during the pouring and curing process. The rigid steel frame serves as a solid foundation for securing the reinforcement bars, preventing any movement or displacement that could compromise the integrity of the structure. This stability ensures that the couplers and splices remain in their intended positions, resulting in a structurally sound and reliable concrete structure. Furthermore, steel frame formwork facilitates efficient and streamlined construction processes for placing reinforcement couplers and splices. The modular nature of the formwork system allows for quick assembly and disassembly, reducing construction time and labor costs. This efficiency leads to a smoother workflow, enabling faster installation of the reinforcement system and overall project completion. In conclusion, steel frame formwork is an ideal choice for handling the placement of reinforcement couplers and splices in concrete structures. Its flexibility, accessibility, stability, and efficiency contribute to the proper integration and positioning of these vital components. By utilizing steel frame formwork, construction projects can benefit from enhanced structural strength, durability, and overall quality.

- Q: Frame structure calculation of the material, the template area, and how to calculate the amount of wood, steel, fasteners, there is no common factor ratio? The column spacing of 6000

- I do not quite understand this knowledge on the Internet to help you find some. See if you can use it

- Q: How does steel frame formwork affect the overall sound insulation of a concrete structure?

- Steel frame formwork does not directly affect the overall sound insulation of a concrete structure. Sound insulation primarily depends on the thickness and density of the concrete, as well as the presence of additional soundproofing materials such as insulation boards or acoustic barriers. The steel frame formwork, which is used as a temporary structure to support the concrete during construction, does not significantly contribute to or diminish the sound insulation properties of the finished concrete structure.

Send your message to us

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords