Frame Connected Scaffolding with High Qulity and Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

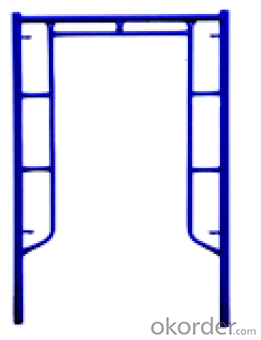

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What are the common industry standards or certifications for steel tube couplers?

- There are several common industry standards and certifications for steel tube couplers. Some of the most widely recognized ones include ISO 9001:2015 for quality management systems, ASTM International standards for materials and product specifications, and the American Welding Society (AWS) certifications for welding processes and procedures. Additionally, some specific certifications may be required for certain industries, such as the API 5CT for oil and gas applications or the ASME BPE for pharmaceutical and bioprocessing equipment.

- Q: How do you ensure proper stability when using steel tube couplers in confined spaces scaffolding?

- When using steel tube couplers in confined spaces scaffolding, there are several measures that can be taken to ensure proper stability: 1. Adequate spacing: Ensure that the steel tube couplers are spaced at regular intervals along the scaffolding structure. This will help distribute the load evenly and prevent any weak points. 2. Secure connections: Make sure that the steel tube couplers are properly tightened and secured to the scaffolding tubes. Loose connections can compromise stability and increase the risk of accidents. 3. Proper alignment: Ensure that the scaffolding tubes are aligned correctly and inserted fully into the steel tube couplers. Misalignment can lead to weak connections and reduced stability. 4. Use of diagonal bracing: Incorporate diagonal bracing within the scaffolding structure to provide additional stability. These braces help to distribute the load more evenly and prevent excessive movement. 5. Regular inspections: Regularly inspect the steel tube couplers and scaffolding structure for any signs of damage or wear. Replace any damaged or worn-out components immediately to maintain the stability and safety of the scaffolding. 6. Ensure proper weight distribution: Avoid placing excessive weight on any single section of the scaffolding. Distribute the load evenly across the structure to prevent overloading and maintain stability. 7. Follow manufacturer guidelines: Always follow the manufacturer's instructions and guidelines when using steel tube couplers in confined spaces scaffolding. This will ensure that you are using the couplers correctly and maximizing their stability. By following these guidelines, you can ensure proper stability when using steel tube couplers in confined spaces scaffolding, minimizing the risk of accidents and creating a safe working environment.

- Q: What are the common safety guidelines for using steel tube couplers in scaffolding?

- When using steel tube couplers in scaffolding, there are several common safety guidelines that should be followed to ensure a safe working environment. These guidelines include: 1. Inspection: Before using steel tube couplers, it is important to inspect them for any signs of damage or wear. If any couplers are found to be damaged, they should be replaced immediately. 2. Proper Installation: Couplers should be installed according to the manufacturer's instructions. This includes ensuring that they are fully tightened and secured to the scaffolding tubes. 3. Load Capacity: Steel tube couplers have a specific load capacity that should not be exceeded. It is important to know the load capacity of the couplers being used and to ensure that the scaffolding is not overloaded. 4. Alignment: Couplers should be properly aligned with the scaffolding tubes to provide maximum strength and stability. Misalignment can weaken the structure and increase the risk of collapse. 5. Regular Inspections: Ongoing inspections should be conducted to check for any signs of damage, wear, or loosening of couplers. Regular inspections help identify potential issues before they become hazardous. 6. Use of Quality Materials: It is important to use high-quality steel tube couplers that meet industry standards. Using substandard or counterfeit couplers can compromise the safety and stability of the scaffolding. 7. Training and Competence: Individuals involved in the assembly, disassembly, and use of scaffolding with steel tube couplers should be properly trained and competent in their use. This includes understanding the proper techniques for erecting and dismantling the scaffolding and knowing how to identify and address any safety concerns. By following these common safety guidelines, the risk of accidents, collapses, or injuries associated with the use of steel tube couplers in scaffolding can be greatly minimized. It is important to prioritize safety and ensure that all necessary precautions are taken to protect workers and prevent accidents.

- Q: Do steel tube couplers have any limitations in terms of tube diameter or thickness?

- There are limitations to steel tube couplers when it comes to tube diameter and thickness. The range of tube sizes that can be connected using the coupler depends on its size and specifications. Steel tube couplers are typically designed to accommodate specific tube diameters and thicknesses. The design and construction of the coupler are based on its intended application and the loads it will handle. If a tube's diameter or thickness exceeds the coupler's specifications, it may not fit properly or compromise the connection's structural integrity. To ensure the chosen steel tube coupler is suitable for the specific tube diameter and thickness, it is important to refer to the manufacturer's specifications and guidelines. Professional engineering advice may also be necessary to determine the appropriate coupler size and compatibility with the desired tube dimensions.

- Q: What is a steel tube coupler in scaffolding?

- Scaffolding employs a steel tube coupler, which effectively links two steel tubes to form a strong and stable structure. This coupler, typically crafted from top-notch steel, is specifically engineered to endure substantial weight and deliver a dependable connection between the tubes. Generally adopting a clamp or sleeve configuration, it incorporates bolts or pins that can be tightened to guarantee a secure and snug fit. As an indispensable element in scaffolding construction, it facilitates the safe and efficient assembly and disassembly of scaffolding structures.

- Q: Can steel tube couplers be used in scaffolding systems with adjustable heights or angles?

- Scaffolding systems with adjustable heights or angles can utilize steel tube couplers. These couplers are specifically designed to connect steel tubes together, ensuring a firm and inflexible bond. In the realm of scaffolding, they are extensively employed to construct durable and steady structures. To achieve adjustable heights or angles in scaffolding systems, adjustable components like telescopic tubes or swivel couplers are commonly employed. These components facilitate the versatility of the scaffolding, enabling it to be set up at varying heights and angles to suit the specific requirements of the construction project. Steel tube couplers possess the adaptability to accommodate adjustments in height or angle by securely connecting the steel tubes in the desired configuration. This secure connection is capable of withstanding the weight and load placed on the scaffolding system, guaranteeing the safety and stability of the structure. It is imperative to ensure that the steel tube couplers utilized in the scaffolding system are of superior quality and adhere to the necessary safety standards. Regular inspections and maintenance ought to be performed to ensure the integrity of the connections and the overall stability of the scaffolding system.

- Q: Building construction bowl button steel pipe scaffolding and fastener scaffolding which cost high

- XPS Extruded polystyrene board: polystyrene is used as raw material plus a simple toilet bowl 丿 stagnation on the lack of other raw materials and fire protection agent, by heating and mixing at the same time into the catalyst, and then squeeze the molding of rigid foam The EPS expansion polystyrene board: is a volatile liquid blowing agent containing polystyrene (eps) beads, preheated by heating after the mold in the mold, with fine closed-cell structure characteristics

- Q: What are the common sizes of steel tube couplers available in the market?

- The common sizes of steel tube couplers available in the market typically range from 1/2 inch to 4 inches in diameter.

- Q: How do steel tube couplers compare to other types of scaffolding connectors?

- Scaffolding systems commonly utilize steel tube couplers, which possess several advantages in comparison to other connector types. Firstly, steel tube couplers exhibit exceptional durability, enabling them to withstand heavy loads and harsh weather conditions. Consequently, they prove suitable for prolonged use in construction projects. Furthermore, steel tube couplers offer versatility by facilitating the connection of tubes at various angles. This flexibility allows for adaptable and flexible scaffolding configurations, rendering them particularly ideal for complex or irregular structures. Moreover, steel tube couplers ensure a secure and stable connection. Their design enables them to tightly grip the tubes, thereby guaranteeing the stability and safety of the scaffolding for workers. This feature holds significant importance in high-risk construction environments. Additionally, steel tube couplers boast a relatively easy installation and dismantling process. They do not necessitate specialized tools or skills, leading to time and labor cost savings. Consequently, construction professionals frequently opt for steel tube couplers due to their user-friendly nature. However, it is essential to acknowledge that steel tube couplers may have certain limitations when compared to alternative connector types. For instance, they may not prove suitable for scaffolding systems requiring quick assembly and disassembly. In such cases, more efficient options like pin and ring systems or snap-on clamps may be preferable. In conclusion, steel tube couplers deliver durability, versatility, and stability within scaffolding systems. Though they may not represent the optimal choice for every situation, their benefits make them a favored option within the construction industry.

- Q: Can steel tube couplers be used in scaffolding projects with specific weight capacity requirements?

- Indeed, scaffolding projects with specific weight capacity requirements can make use of steel tube couplers. These couplers are frequently employed in scaffolding systems to interconnect steel tubes, thereby furnishing stability and reinforcement. They are purposefully constructed to endure substantial loads and possess weight capacity ratings tailored to their design. Consequently, it is crucial to meticulously choose the couplers that satisfy the weight capacity prerequisites of the scaffolding project. Furthermore, it is imperative to regularly inspect and maintain the couplers to secure their enduring robustness and dependability.

Send your message to us

Frame Connected Scaffolding with High Qulity and Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches