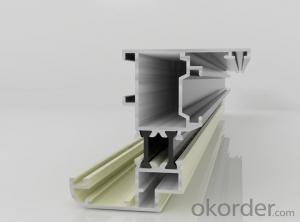

Factory Low Price Extruded Aluminum Heat Sink Profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the vibration damping properties of aluminum profiles?

- Aluminum profiles exhibit good vibration damping properties due to their inherent material properties, such as high stiffness and low density. These properties enable the profiles to effectively absorb and dissipate vibrations, reducing their transmission through the structure. Additionally, aluminum profiles can be further enhanced with damping materials or techniques to improve their vibration damping capabilities.

- Q: How can the aluminum profile T6 and T5 be distinguished?

- Hardness is generally measured by a Brinell hardness tester. T5 is subjected to high temperature molding and air cooling quenching in the shortest possible time. The T6 is treated with solid solution after artificial aging. So there is a difference between the two. But from the appearance of it is difficult to judge, experienced hands can be used to swing aluminum, roughly judged

- Q: Are aluminum profiles suitable for use as interior finishing materials, specifically for flooring and wall panels?

- <p>Yes, aluminum profiles can be used for interior finishing materials such as flooring and wall panels. They are known for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are lightweight, easy to install, and can be used in various designs and styles, making them a popular choice for modern interior design. They also offer the advantage of being recyclable and environmentally friendly.</p>

- Q: What are the different packaging options for aluminum profiles?

- There are several packaging options available for aluminum profiles, depending on the specific requirements and preferences of the customers. Some of the common packaging options include: 1. Bundles: Aluminum profiles can be packed in bundles, where several profiles of the same length and shape are bundled together using straps or bands. This packaging option is ideal for smaller profiles and offers easy handling and transportation. 2. Wooden crates: For larger or more fragile aluminum profiles, wooden crates are often used. The profiles are securely placed inside the crate and then nailed or screwed shut. Wooden crates provide excellent protection during shipping and can be customized to fit the specific dimensions of the profiles. 3. Cardboard tubes: Thin and lightweight aluminum profiles, such as those used in the packaging industry, can be packaged in cardboard tubes. These tubes provide a cost-effective and lightweight solution for transportation and storage, while still offering adequate protection. 4. Pallets: When dealing with a large volume of aluminum profiles, pallets are often used for packaging. Profiles are stacked and secured on a pallet using strapping or shrink wrap. This packaging option allows for efficient handling, as pallets can be easily loaded and unloaded using forklifts or pallet jacks. 5. Custom packaging: Customers may have unique packaging requirements based on their specific needs. In such cases, custom packaging options can be developed, such as foam inserts, plastic wraps, or specific labeling. Custom packaging ensures that the profiles are adequately protected and that any specific handling instructions are followed. In summary, the packaging options for aluminum profiles can vary depending on factors like profile size, fragility, and volume. Whether it's bundling, wooden crates, cardboard tubes, pallets, or custom packaging, each option offers its own benefits in terms of protection, handling, and ease of transportation.

- Q: Can aluminum profiles be used in the production of audiovisual equipment?

- Yes, aluminum profiles can be used in the production of audiovisual equipment. Aluminum is a lightweight and durable material that can be easily molded into various shapes and designs. It offers excellent heat dissipation properties and is resistant to corrosion, making it suitable for audiovisual equipment such as speaker stands, camera mounts, and TV brackets. Additionally, aluminum profiles can be customized to fit specific requirements, providing flexibility in design and construction.

- Q: Can aluminum profiles be used for window frames?

- Yes, aluminum profiles can be used for window frames. Aluminum is a popular material for window frames due to its lightweight, strength, and durability. It is resistant to corrosion, so it is ideal for windows in coastal areas or places with high humidity. Aluminum frames also offer a sleek and modern appearance that complements various architectural styles. Additionally, aluminum is a sustainable material as it can be recycled, making it an environmentally friendly choice for window frames.

- Q: Are there various ways to install aluminum profiles?

- <p>Yes, aluminum profiles can be installed using different methods. Common installation techniques include direct fastening with screws or bolts, using adhesives or sealants, and employing clip or channel systems. The choice of method depends on the specific application, load-bearing requirements, and aesthetic considerations. Some methods may provide quicker installation, while others might offer better structural integrity or visual appeal. It's important to consult with a professional or follow manufacturer guidelines to ensure the proper installation method is used for the intended application.</p>

- Q: What are the differences between the 6005 and 6003 aluminum profiles?Yangmingxg3

- 6003 of the magnesium content is higher than 6005, and the strengthening of magnesium to aluminum is remarkable. With the addition of 1% mg, the tensile strength increases by about 34MPa.

- Q: Are aluminum profiles suitable for use in aerospace structural components?

- Yes, aluminum profiles are suitable for use in aerospace structural components. Aluminum is a lightweight and corrosion-resistant material that offers a high strength-to-weight ratio, making it ideal for applications in the aerospace industry. It is widely used in the construction of aircraft frames, wings, and other structural components due to its durability and ability to withstand high stress and forces during flight.

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Factory Low Price Extruded Aluminum Heat Sink Profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords