Mill Finished Aluminum Sheets for Building Roofing - West Virginia

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminium Sheet for Building Roofing

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminium Sheet for Building Roofing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminium Sheet for Building Roofing

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

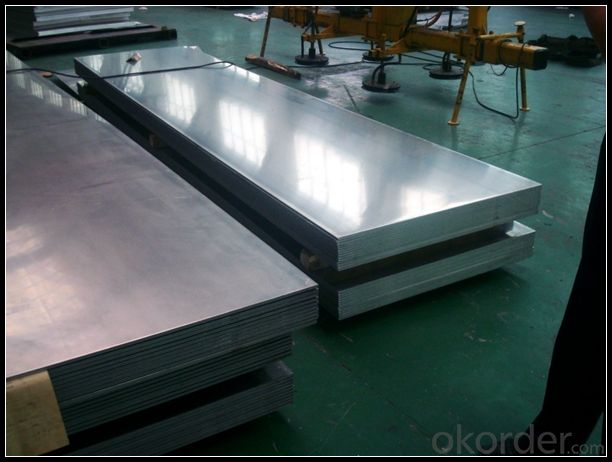

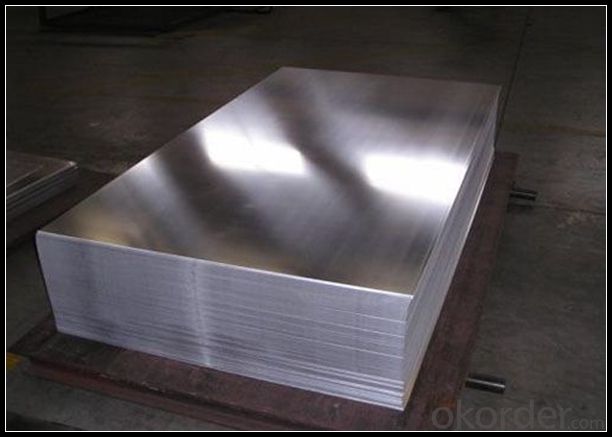

5. Image of Mill Finished Aluminium Sheet for Building Roofing

6. Package and shipping of Mill Finished Aluminium Sheet for Building Roofing

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets varies depending on the alloy and temper. However, a commonly used value is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This value represents the stiffness or rigidity of the material, indicating its ability to withstand deformation under applied stress. It is important to note that different grades and conditions of aluminum may have slightly different modulus of elasticity values, so it is recommended to consult the specific material specifications for accurate information.

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Yes, aluminum sheets can be used for manufacturing food packaging. Aluminum is a popular choice for food packaging due to its non-reactive nature, resistance to corrosion, and ability to maintain the freshness and quality of food products.

- Q: Is aluminum sheet recyclable?

- Yes, aluminum sheet is highly recyclable.

- Q: Are aluminum sheets suitable for automotive body reinforcements?

- Yes, aluminum sheets are suitable for automotive body reinforcements. Aluminum is lightweight yet strong, making it an ideal material for reinforcing automotive bodies. It offers several advantages such as improved fuel efficiency, increased load-bearing capacity, and enhanced safety. Additionally, aluminum is resistant to corrosion, which ensures the longevity of automotive body reinforcements.

- Q: This question asks for methods to protect aluminum sheets from damage during the installation process.

- <p>To prevent damage to your aluminum sheets during installation, follow these steps: Use protective gloves to avoid scratches from hand contact. Handle the sheets with care, especially at the edges and corners. Keep the surface clean and dry to prevent any dirt or moisture that could cause damage. Use appropriate tools designed for aluminum to avoid marring the surface. Ensure the installation site is free from debris that could cause scratches or dents. Install the sheets in a controlled environment to avoid exposure to harsh weather conditions. Finally, consider using a protective film or cover on the aluminum sheets until they are fully installed.</p>

- Q: Can aluminum sheets be painted?

- Yes, aluminum sheets can be painted. However, it is important to properly prepare the surface by cleaning, sanding, and using a primer specifically formulated for metal surfaces to ensure good adhesion of the paint.

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- Aluminum foil will absorb heat, just like any other metal (and anything for that matter, but this isn't a discussion about conductors vs. insulators). Whether aluminum foil absorbs heat is the essential issue here. A car gets hot in the sun as a result of the sunlight shining on the car. When the sun shines on a car, the light passes through the windows (because windows are clear) and is absorbs by the interior of the car (e.g. the seat cushions). The absorbed energy is given off as heat, which is trapped in the car (heat doesn't pass through windows like sunlight does). By putting aluminum reflectors in your windshield, you are reflecting away the light and preventing it from reaching the interior of your car. For this reason, putting aluminum shielding in the windows of your car actually keeps your car cooler, and not hotter.

- Q: This question asks for a list of various standard sizes of aluminum sheets that are commonly available in the market.

- <p>Aluminum sheet sizes can vary widely depending on the application and industry standards. Commonly available sizes include 1/8 inch, 1/4 inch, 3/8 inch, and 1/2 inch thicknesses, with widths ranging from 12 inches to 60 inches. Lengths can be from 4 feet to 20 feet or more. However, specific sizes can differ based on regional standards and manufacturers' offerings. It's also important to note that custom sizes can be ordered to meet specific project requirements. Always check with suppliers for the most current and detailed list of available sizes.</p>

- Q: What are the typical uses or applications for 101 aluminum sheets?

- 101 aluminum sheets are commonly used in a variety of applications such as roofing, siding, gutters, and general construction due to their excellent corrosion resistance, high formability, and durability. They are also utilized in the automotive industry for body panels, trims, and interior components. Additionally, 101 aluminum sheets are often used for packaging, electrical enclosures, and kitchen equipment due to their lightweight nature and ability to withstand various environmental conditions.

Send your message to us

Mill Finished Aluminum Sheets for Building Roofing - West Virginia

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords