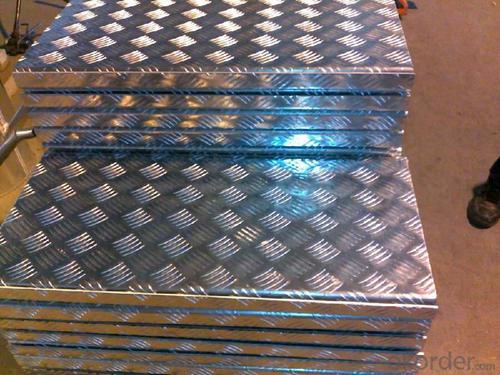

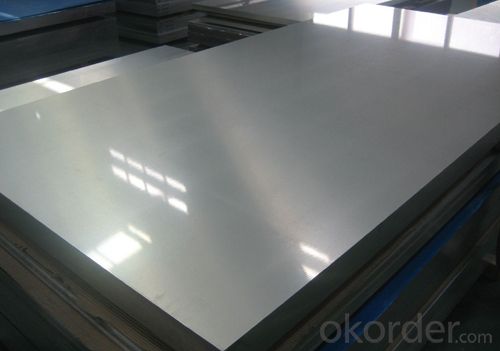

Mill Finished Aluminum Sheets for Embossing and Roofing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finished Aluminium Plate For Decoration Roofing Production

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 18MT | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 20-30 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

PVDF color pre coated aluminum coils/ sheets:

It is well known that fluorocarbon lacquer coating (PVDF coating) owes the best acid resistant/alkali and temperature tolerant capabilities of all painting materials. Being the best quality of precoated aluminum, PVDF coated coils are especially suitable for outdoor roofing walls and ceiling manufacturing.

Polyester (PE) color pre coated aluminum coils/ sheets :

Using high-grade polyester lacquer coating material, the finished coated coils are with delicate color uniform texture, color and diverse. It is the most popular and most common used materials in decorative usage. The PE coated aluminum are widely used in ACP( aluminum composite panel ) production and indoor ceiling usage.

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: do recycling centers take already compacted aluminum cans? Link is below. if not then why are so many people making homemade can crushers?

- Yes they do. At one point there was a contest to make your own can crusher and post the video for the life of me I cannot remember what it was for anymore.

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: Is it suitable to use aluminum sheets in environments with high moisture levels?

- <p>Yes, aluminum sheets can be used in areas with high humidity. Aluminum is a corrosion-resistant metal that does not rust, making it suitable for humid environments. However, it's important to ensure that the aluminum is properly coated or anodized to protect it from potential damage due to moisture. This treatment can prevent any form of corrosion and extend the life of the aluminum sheets.</p>

- Q: What are the standard sizes of aluminum sheets?

- The standard sizes of aluminum sheets can vary depending on the manufacturer and specific requirements. However, some commonly available standard sizes for aluminum sheets include 4 feet by 8 feet (1.2 meters by 2.4 meters), 4 feet by 10 feet (1.2 meters by 3 meters), and 5 feet by 10 feet (1.5 meters by 3 meters). These sizes are widely used in various industries and are readily available in the market. Additionally, custom sizes can also be obtained through specialized aluminum sheet suppliers to meet specific project needs.

- Q: Do 101 aluminum sheets have any specific anti-corrosion properties?

- Yes, 101 aluminum sheets do have specific anti-corrosion properties. Aluminum naturally forms a protective oxide layer on its surface when exposed to oxygen, which acts as a barrier against corrosion. This oxide layer, also known as aluminum oxide, is highly resistant to rust and corrosion. Additionally, 101 aluminum sheets are alloyed with small amounts of iron and silicon, which further enhance their corrosion resistance. These sheets are often used in applications where corrosion resistance is crucial, such as in marine environments, chemical processing plants, and outdoor structures. However, it's important to note that while aluminum is highly resistant to corrosion, it can still be susceptible to certain types of corrosion in specific conditions, such as pitting corrosion in chloride-rich environments. Therefore, proper care and maintenance should still be followed to ensure the longevity and effectiveness of 101 aluminum sheets in preventing corrosion.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: What are aluminum sheets made of?

- Aluminum sheets are primarily made of aluminum, a lightweight and malleable metal that is extracted from bauxite ore through a refining process.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically classified as Class A, indicating a high level of fire resistance.

- Q: This question asks for a list of various adhesive types that are suitable for bonding aluminum sheets together.

- <p>There are several types of adhesives used for bonding aluminum sheets, including epoxy adhesives, which are strong and resistant to heat and chemicals; acrylic adhesives, known for their flexibility and UV resistance; cyanoacrylate or super glue, which offers fast bonding; polyurethane adhesives, providing excellent adhesion and durability; and silicone adhesives, which are great for high-temperature applications. Each type has its specific properties and applications, making them suitable for different bonding requirements and environmental conditions.</p>

- Q: Calculate the molar mass of the aluminum oxide. A 5.00g strip of aluminum is reacted in air, producing an oxide weighing 9.36g. Calculate the percent oxygen and aluminum in the compound.Calculate the % error for percent of aluminum calculated.

- molar mass.. .. molar mass Al2O3 = 2 x 26.98 + 3 x 16.00 = 101.96 g/mol mass %'s based on formula .. % Al in Al2O3 = (2 x 26.98 / 101.96) x 100% = ___ % .. % O in Al2O3 = (3 x 16.00 / 101.96) x 100% = ___ % mass % based on experimental data .. % Al in oxide = (5.00g / 9.36g) x 100% = ___% .. % O in oxide = ( (9.36g - 5.00g) / 9.36g) x 100% = __ % and finally .. % error = (|measured - accepted| / |accepted|) x 100% = ___% ********* here's the answer for the ALUMINUM calcs .. % Al in Al2O3 = (2 x 26.98 / 101.96) x 100% = 52.92% .. % Al in oxide = (5.00g / 9.36g) x 100% = 53.42% .. % error = ( | 53.42% - 52.92% | / | 52.92% | ) x 100% = 0.95% you get to do the oxygen calcs

Send your message to us

Mill Finished Aluminum Sheets for Embossing and Roofing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords