18in Mill Finish Aluminum Sheets for Metal Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet for Metal Roofing

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finish Aluminum Sheet for Metal Roofing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet for Metal Roofing

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

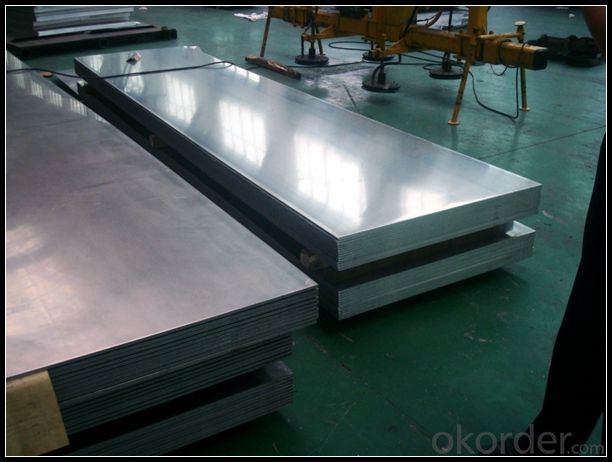

5. Image of Mill Finish Aluminum Sheet for Metal Roofing

6. Package and shipping of Mill Finish Aluminum Sheet for Metal Roofing

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Aluminum sheets are indeed appropriate for utilization in the food processing and packaging sectors. The food industry extensively employs aluminum due to its exceptional properties and advantages. To begin with, aluminum is a safe material for direct contact with food as it is non-toxic. It does not react with food or affect its taste, guaranteeing the preservation of the original flavor and quality. This is particularly crucial in packaging, as it aids in maintaining the freshness and integrity of the food product. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient and uniform heat distribution during food processing. This attribute is advantageous in cooking, baking, and other thermal procedures, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets exhibit outstanding barrier properties, including resistance to moisture, light, and gases. This shields food from external factors that could potentially degrade its quality, such as moisture or oxygen. It also extends the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet sturdy and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and safeguards the food during transportation and storage. Lastly, aluminum is an environmentally sustainable material. It is fully recyclable, meaning it can be reused without losing its properties. This aids in reducing the environmental impact and supports the concept of a circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: 2mm aluminum welding with oxygen welding or argon arc welding good?

- 2 mm thickness of aluminum welding, argon arc welding preferred.2 mm thickness aluminum plate, in order to ensure the quality of welding and weld strength, the first choice should be: inverter square wave pulse TIG welding machine welding. According to the specific material and grade of the aluminum plate, the aluminum welding wire matched with the base material is selected.

- Q: What are the standard dimensions of aluminum sheets?

- The specific industry and application determine the varying standard dimensions of aluminum sheets. However, there are commonly available sizes that are commonly used. For general purposes, aluminum sheets are commonly found in dimensions of 4 feet by 8 feet (1219mm x 2438mm) and 4 feet by 10 feet (1219mm x 3048mm). These dimensions, often referred to as "full sheets," are widely used in construction, manufacturing, and signage industries. Aside from full sheets, smaller sizes of aluminum sheets are also available, such as 2 feet by 4 feet (609mm x 1219mm) and 2 feet by 8 feet (609mm x 2438mm). These smaller sizes are commonly used for DIY projects, crafts, and hobbies. It is important to note that although these dimensions are standard, aluminum sheets can be custom cut to meet specific sizes and shapes for individual project requirements. This provides greater flexibility and versatility across various industries. Ultimately, the choice of aluminum sheet dimensions depends on the specific needs of the project, industry standards, and personal preferences.

- Q: Can aluminum sheets be used for heat sinks?

- Indeed, heat sinks can utilize aluminum sheets. Due to its outstanding thermal conductivity, aluminum serves as an ideal substance for efficiently diverting heat away from electronic parts. With the ability to be fashioned into different dimensions and configurations, aluminum sheets can optimize the dispersion of heat. They find widespread employment in computer processors, LED lights, and power electronics, where the preservation of peak performance and the prevention of overheating hinge on effective heat dissipation. Moreover, the lightweight nature and cost-effectiveness of aluminum sheets render them highly favored for heat sink purposes.

- Q: What are the different thicknesses available for aluminum sheet?

- Aluminum sheets come in various thicknesses, spanning from very thin to thick. The thickness of these sheets is measured either in gauge or millimeters (mm), with each gauge denoting a specific thickness. The prevalent gauges for aluminum sheets are 22, 24, 26, 28, 30, and 32, corresponding to thicknesses ranging from 0.0254 mm to 0.635 mm. Moreover, thicker gauges, such as 16 gauge (1.29 mm) or even more substantial ones, can be found for specialized applications. The preferred thickness of an aluminum sheet is determined by its intended use. Thinner sheets are often utilized for lightweight purposes, including electronics or packaging, while thicker sheets are more suitable for structural or industrial needs.

- Q: What are the different methods of surface embossing aluminum sheets?

- Aluminum sheets can be embossed using various techniques, each with its own distinct process and result. Some commonly employed methods are: 1. Mechanical Embossing: To create patterns or designs on the aluminum sheet, mechanical tools like rollers or presses are utilized. The sheet is either passed through the rollers or pressed against a surface with a pattern, which impresses the design onto the metal. Mechanical embossing is ideal for repetitive patterns like diamond or checkerplate designs. 2. Chemical Embossing: This technique involves etching or engraving the aluminum sheet using chemical solutions. The solution is selectively applied to the metal's surface, eating away the desired areas to leave an embossed pattern. Chemical embossing enables the creation of intricate and detailed designs on the aluminum sheet. 3. Heat Embossing: By applying heat, embossed designs are formed on the aluminum sheet. A heated die or stamp is pressed onto the metal's surface, causing it to deform and create the desired pattern. Heat embossing is commonly used for raised logos or text on aluminum sheets. 4. Laser Embossing: Laser technology is employed to achieve embossed designs on aluminum sheets. A laser beam is directed onto the metal's surface, vaporizing or melting the desired areas to form the embossed pattern. Laser embossing offers high precision and allows for intricate and complex designs. 5. Roll Embossing: In this method, the aluminum sheet is passed through a series of engraved rolls, which imprint the desired pattern onto the metal. Each roll has a distinct design, providing a range of embossed finishes. Roll embossing is often used for textured or decorative finishes on aluminum sheets. In conclusion, the various techniques for surface embossing aluminum sheets offer multiple options for creating visually appealing and unique designs. The choice of method depends on the desired outcome, complexity of the design, and specific project requirements.

- Q: Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q: you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

- Q: Can aluminum sheet be anodized?

- Indeed, it is possible to anodize aluminum sheet. Anodization, an electrochemical process, fortifies the natural oxide layer on the aluminum's surface, resulting in increased thickness, durability, and suitability for diverse applications. The procedure entails submerging the aluminum sheet into an electrolyte solution and passing an electric current through it. This prompts the release of oxygen ions from the electrolyte, which then combine with the aluminum, generating a fresh layer of aluminum oxide. Anodization allows for the creation of an array of colors on the aluminum sheet's surface, enhances its resistance to corrosion, and provides an improved surface for the adhesion of paints or coatings.

Send your message to us

18in Mill Finish Aluminum Sheets for Metal Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords