Aluminum Sheets in Wyoming - Aluminum Sheet and Mill Finished Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description

Aluminium atoms are arranged in a face-centered cubic (fcc) structure. Aluminium has a stacking-fault energy of approximately 200 mJ/m2.

Aluminium is a good thermal and electrical conductor, having 59% the conductivity of copper, both thermal and electrical, while having only 30% of copper's density. Aluminium is capable of being a superconductor, with a superconducting critical temperature of 1.2 Kelvin and a critical magnetic field of about 100 gauss (10 milliteslas).

2.Chemical

Corrosion resistance can be excellent due to a thin surface layer of aluminium oxide that forms when the metal is exposed to air, effectively preventing further oxidation.The strongest aluminium alloys are less corrosion resistant due to galvanic reactions with alloyed copper.This corrosion resistance is also often greatly reduced by aqueous salts, particularly in the presence of dissimilar metals.

In highly acidic solutions aluminium reacts with water to form hydrogen, and in highly alkaline ones to form aluminates— protective passivation under these conditions is negligible. Also, chlorides such as common sodium chloride are well-known sources of corrosion of aluminium and are among the chief reasons that household plumbing is never made from this metal.

However, owing to its resistance to corrosion generally, aluminium is one of the few metals that retain silvery reflectance in finely powdered form, making it an important component of silver-colored paints. Aluminium mirror finish has the highest reflectance of any metal in the 200–400 nm (UV) and the 3,000–10,000 nm (far IR) regions; in the 400–700 nm visible range it is slightly outperformed by tin and silver and in the 700–3000 (near IR) by silver, gold, and copper.

3. Specification

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

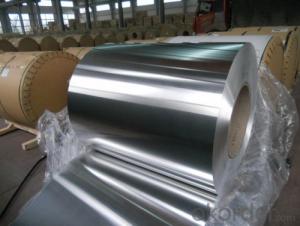

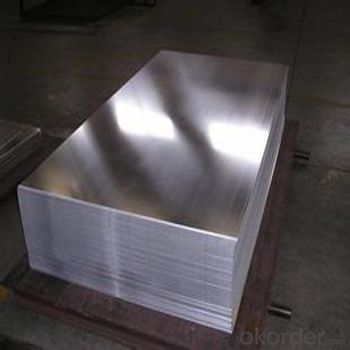

4.Picture

5.FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the weight of the aluminum sheets?

- The weight of the aluminum sheets will depend on their size and thickness.

- Q: How are aluminum sheets typically packaged for shipping?

- Aluminum sheets are typically packaged for shipping by being stacked together and secured with straps or bands. They may also be placed in crates or on pallets to provide additional protection during transport.

- Q: What are the different types of finishes used for decorative aluminum sheet?

- The different types of finishes used for decorative aluminum sheet include brushed, polished, anodized, embossed, and powder coated finishes.

- Q: How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- They don't make aluminum siding anymore, thank god, they only make vinyl siding. It really depends on the brand you buy and the company that installs it. I used to be a tin man before becoming a professor and I can tell you that you should do a little research first. You want stuff that will hold up in wind, is easy to clean, has a nice look and colors won't fade. You want to be sure it is made of virgin vinyl, sounds weird but trust me, if it isn't it'll fade in a few years and look like crap. The company needs to know what they are doing too or the seams and lines will be terrible, so make sure your company is really in the siding business and not just some jack-leg contractor that says I can do it. You will end up with a crap job. Now I can't remember for certain and it has been a number of years, but 10 to 12 sounds good. I hope they are going to remove the old stuff, check your wood underneath and possibly put on a moisture barrier. I would ask what they plan on doing in detail. Good luck.

- Q: you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q: Can aluminum sheets be used for pharmaceutical lab equipment?

- Aluminum sheets have the capability to be utilized in pharmaceutical lab equipment. Aluminum, a versatile material, offers numerous benefits for pharmaceutical applications. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity make it an excellent option for constructing trays, shelves, and cabinets that are employed for storing and transporting pharmaceutical substances. Moreover, aluminum can be easily sterilized and cleaned, which is vital for maintaining hygienic conditions in pharmaceutical laboratories. Nevertheless, it is crucial to acknowledge that specific pharmaceutical procedures may demand materials that comply with particular regulatory standards. Thus, it is always wise to seek advice from industry experts or regulatory bodies to ensure that the selected aluminum sheets fulfill the necessary requirements for their intended usage in pharmaceutical lab equipment.

- Q: How do you protect aluminum sheets from scratches?

- To protect aluminum sheets from scratches, there are a few steps you can take: 1. Handle with care: When handling aluminum sheets, always be mindful of their vulnerability to scratches. Avoid dragging or sliding them across rough surfaces, as this can cause scratches. Instead, lift and place them gently, ensuring you have a clean, smooth surface to work on. 2. Use protective covering: Before storing or transporting aluminum sheets, consider using a protective covering such as a plastic film or paper. This will provide a barrier and prevent direct contact with other surfaces, reducing the risk of scratches. Ensure that the covering is clean and free from any dirt or debris. 3. Store in a safe environment: When not in use, store aluminum sheets in a clean and dry environment. Avoid storing them alongside abrasive materials or objects that could potentially scratch them. Additionally, consider using dividers or separators to create individual compartments for each sheet, preventing them from rubbing against each other. 4. Clean with caution: When cleaning aluminum sheets, use a soft, non-abrasive cloth or sponge. Avoid using wire brushes or rough materials that can cause scratches. Additionally, use a mild detergent or aluminum cleaner specifically designed for this purpose. Rinse thoroughly and dry the sheets completely to prevent any moisture from causing damage. 5. Apply a protective coating: Another option to protect aluminum sheets from scratches is to apply a protective coating. There are various types of coatings available, such as clear lacquers or specialized aluminum protectants. These coatings create a thin barrier on the surface of the aluminum, adding an extra layer of protection against scratches. By following these steps, you can significantly reduce the risk of scratches on your aluminum sheets and help maintain their appearance and integrity over time.

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Aluminum sheets are indeed suitable for the production of aircraft parts. They are a lightweight and durable material commonly utilized in the aerospace sector. With its exceptional strength-to-weight ratio, corrosion resistance, and excellent formability, aluminum is ideal for various applications in aviation. It is effortless to fabricate aluminum sheets into intricate shapes, making them perfect for manufacturing aircraft wings, fuselages, panels, and structural supports. Moreover, aluminum's high conductivity facilitates efficient heat dissipation in crucial areas of the aircraft. Consequently, aluminum sheets are widely preferred for aircraft part manufacturing due to their desirable properties and reliability in the aerospace field.

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity and is commonly used in electrical wiring, power transmission lines, and electrical enclosures.

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- There are several advantages of using aluminum sheets in the furniture industry. Firstly, aluminum is lightweight yet strong, making it easier to handle and transport furniture. Secondly, aluminum is resistant to corrosion, ensuring the durability and longevity of furniture products. Additionally, aluminum sheets can be easily molded and shaped into various designs, allowing for creative and unique furniture pieces. Lastly, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for the furniture industry.

Send your message to us

Aluminum Sheets in Wyoming - Aluminum Sheet and Mill Finished Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords