Mill Finished Aluminum Sheets Dallas Texas for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Alloy 1100 Flat Aluminum Sheet for Circuit Board

l Product Introduction

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

l Product Description

1060,1200,1070,1080,1100,a1100P,3003,3004,5052,5652,5154,5254,5454,5083,5754,

5086,5056,5456,2A12,2024,2014,6061,6062,6063,6082,7003,7004,7075,8010,8020,etc

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

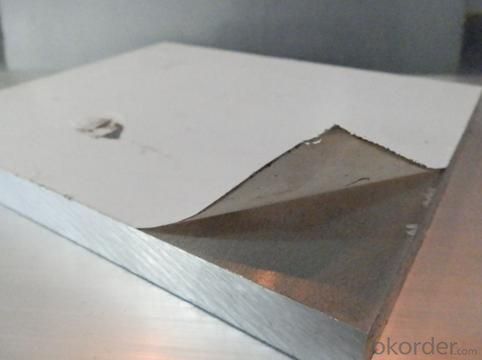

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- The spec for 6061 aluminium, can be found on this link - 66.102.9.104/search?q=cache:ALU5S...

- Q: Are aluminum sheets fire-resistant?

- Aluminum sheets are not inherently fire-resistant, but they do have properties that make them more fire-resistant compared to other materials. Aluminum has a high melting point of 1220°F (660°C), which means it will not ignite or burn easily under normal conditions. Additionally, aluminum has a low ignition temperature and does not release flammable gases when heated. When exposed to fire, aluminum sheets form a protective oxide layer that acts as a barrier, preventing further combustion and slowing down the spread of flames. This oxide layer also helps to insulate the aluminum from the heat, reducing the risk of structural failure. However, it is important to note that while aluminum sheets have better fire resistance than materials like wood or plastic, they can still be damaged or deformed by intense heat. Therefore, it is crucial to consider other fire safety measures, such as using fire-resistant coatings or implementing fire suppression systems, in order to ensure maximum protection against fire hazards.

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: What are the surface treatment requirements for aluminum sheets in the food industry?

- In the food industry, aluminum sheets used for food packaging and handling must undergo specific surface treatments to meet hygiene and safety standards. The surface treatment requirements for aluminum sheets in the food industry typically involve processes like cleaning, degreasing, and anodizing. These treatments remove any dirt, oils, or contaminants, and create a protective layer on the aluminum surface to prevent corrosion and ensure the sheets are safe for food contact. Additionally, the surface treatments may also include specific coatings or laminations to enhance the barrier properties and maintain the quality and freshness of the food products.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding is a welding method that pressing the materials to be welded in an area between two poles and switching on current. the current will go through the contact surface and agjacent area, producing resistance heat effect which will heatthe materials into melting or plastic state and make the materials be welded together.

- Q: 10mm how much is the aluminum sheet?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liaoning Wang Zhong Nanshan aluminum do this thickness.

- Q: Can aluminum sheet be used in marine environments?

- Certainly, aluminum sheet finds utility in marine environments. The corrosion resistance exhibited by aluminum renders it a favored material for marine purposes. The formation of a safeguarding oxide layer on its exterior effectively curbs corrosion, even in the presence of saltwater. Moreover, aluminum's lightweight nature qualifies it as an optimal selection for marine applications where weight reduction is paramount. Given its robustness, strength, and corrosion resistance, aluminum sheet is extensively employed in boat hulls, decks, and various other marine constructions.

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity and is commonly used in electrical wiring, power transmission lines, and electrical enclosures.

- Q: Are 101 aluminum sheets suitable for aerospace tooling?

- No, 101 aluminum sheets are not suitable for aerospace tooling.

Send your message to us

Mill Finished Aluminum Sheets Dallas Texas for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords