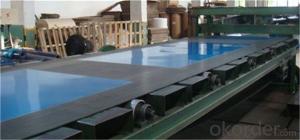

China Aluminum Wall Sheets - Mill Finish Mirror 3mm 5mm 8mm Pure 1050 1060 1070 Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- they can be made outta plastic or wood, prboably something else..but i can't thnk of it. ive had a plastic 1 and it still worked great..even though it was the ch eapest grinder in the store. so..personal preference really. gl

- Q: How do aluminum sheets perform in terms of thermal expansion?

- Aluminum sheets have a relatively high coefficient of thermal expansion, meaning they expand significantly when exposed to heat and contract when cooled. This is due to the nature of aluminum as a metal, which has a relatively low melting point and is known for its ability to conduct heat efficiently. When aluminum sheets are heated, the increased energy causes the metal atoms to vibrate and move more rapidly, resulting in expansion. Conversely, when aluminum sheets are cooled, the decrease in energy causes the metal atoms to slow down and move closer together, leading to contraction. It is important to consider the thermal expansion properties of aluminum sheets when using them in applications where temperature changes are expected, as this can affect the overall dimensions and performance of the material.

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets differs based on the specific alloy employed. On average, aluminum exhibits a coefficient of thermal expansion of around 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). Consequently, with each degree rise in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It should be emphasized that this figure might vary slightly among diverse grades and alloys of aluminum.

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Yes, aluminum sheets are suitable for manufacturing electrical enclosures. Aluminum is a highly versatile and widely used material in the manufacturing industry, including for electrical enclosures. It offers several advantages that make it suitable for this application. Firstly, aluminum is lightweight yet strong, making it ideal for constructing enclosures that need to be durable while also being easily transportable and installable. Its strength-to-weight ratio is higher than many other metals, allowing for the creation of sturdy enclosures without adding unnecessary weight. Secondly, aluminum has excellent corrosion resistance. This is crucial for electrical enclosures as they are often placed in various environments where they may be exposed to moisture, humidity, or other corrosive elements. Aluminum's natural oxide layer provides a protective barrier against corrosion, ensuring the longevity and reliability of the enclosures. Additionally, aluminum is a good conductor of electricity, which is another important characteristic for electrical enclosures. It allows for efficient dissipation of heat generated by electrical components, preventing overheating and potential damage to the enclosed devices. Furthermore, aluminum is easily machinable and can be formed into various shapes and sizes. This flexibility allows manufacturers to customize the enclosures according to specific requirements, ensuring a perfect fit for the intended electrical components. Lastly, aluminum is a cost-effective material compared to other metals like stainless steel or copper. It offers a good balance between affordability and performance, making it an attractive choice for manufacturing electrical enclosures. In conclusion, aluminum sheets are indeed suitable for manufacturing electrical enclosures due to their lightweight, strength, corrosion resistance, electrical conductivity, machinability, and cost-effectiveness.

- Q: what's the size of aluminum sheet circle?

- Aluminum sheet circle’s size is usually the width of coil stock (mm) : 500-1250,800-1400,1000-1600, thickness of coil stock (mm) : 0.4-3.0,1.0-6.0, weight of coil stock (kg) : 8000,10000, diameter of blank(mm) : 85-660,85-750,100-900. Aluminum sheet circle is broadly used in electron, daily chemical industry, medicine, education and car accessories industry. Electrical appliance, thermal insulation, machine manufacturing, cars, spaceflight, military industry, mould, construction, printing and other industries. Kitchenware, such as non-stick pan, pressure cooker, etc. and hardware, such as lampshade, shell of water heater, etc. they are one of the highly processed aluminum products with largest consumption.

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- This Site Might Help You. RE: which has the lower melting temperature....aluminum, copper, or brass...can you list all 3? I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- Q: Status of aluminum sheet F

- H is the hardening state, should be followed by a digital representation of what the work hardening and degree of hardness, suitable to improve the strength of the product through the hardening product in hardening after after (or not after) additional heat treatment makes the strength decreased.The status of aluminum sheet is basically divided into five kinds, in addition to the above three kinds, there are two kinds of W and T:W solid fusion heat treatment state, an unstable state, is only applicable to naturally aged alloy at room temperature after solid solution heat treatment.

- Q: i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- I doubt the ground wire is Aluminum, more likely it is tinned copper. Check by bending it, copper bends easier than aluminum, compare to the fixture wires. To connect copper wire to aluminum wire you need special conductive paste and connectors certified for CU/ AL.

- Q: Can aluminum sheets be used for flooring?

- Indeed, flooring can utilize aluminum sheets. Lightweight and sturdy, aluminum proves resistant to corrosion, rendering it an appropriate option for a range of flooring uses. Notably, aluminum sheets frequently find employment in industrial, commercial, and residential settings, encompassing warehouses, garages, kitchens, and outdoor areas. These sheets offer commendable strength, effortless installation, and minimal upkeep. Furthermore, aluminum flooring imparts a polished and contemporary aesthetic to any given space. Nevertheless, prudent consideration of factors like thickness, finish, and the unique demands of the flooring project becomes imperative prior to settling on aluminum sheets.

Send your message to us

China Aluminum Wall Sheets - Mill Finish Mirror 3mm 5mm 8mm Pure 1050 1060 1070 Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords