Industrial Aluminum Foil Sheets - Aluminum Sheet Mill Finished 1060 1050 1100 3003 5005 5052 6061 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

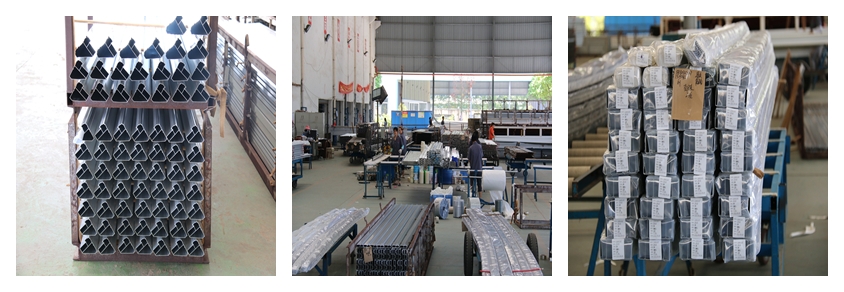

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Yes, 101 aluminum sheets can be used in HVAC systems. Aluminum is commonly used in HVAC systems due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. The 101 aluminum alloy is a commonly used grade that provides good strength and ductility, making it suitable for HVAC applications. It is often used for fabricating ducts, air handlers, heat exchangers, and other components in HVAC systems. Additionally, aluminum sheets are easy to work with and can be easily formed and shaped according to the specific requirements of the HVAC system.

- Q: how many protons,nuetrons, and electrons are in aluminum?

- Aluminum is element 13, so it has 13 protons. This also means that it normally has 13 electrons (provided it is not in an ionic state). Normally it has 14 neutrons, but may have less or more in various isotopes.

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- The difference is as follows: 1, different layers: single aluminum plate is divided into two layers, the surface layer is aluminum skin, second layers of plastic, aluminum plate is divided into three layers: the surface layer and the third layer is an aluminum sheet, the middle is plastic, or aluminum plate than single aluminum plate a layer of aluminum skin; 2, the quality of different because: aluminum sheet aluminum plastic board less than a layer of aluminum skin, so the single aluminum plate than the aluminum plate quality will certainly be worse; 3, the price is different: single aluminum plate is cheaper than aluminum plate, aluminum plate positioning for low-grade, aluminum-plastic plate according to the quality and thickness of plastic and aluminum skin into the middle different grades, but certainly more than the single aluminum plate and expensive; 4, the construction effect is certainly not the same: a plastic plate can be slotted, bending turning construction construction, suitable for a variety of occasions, but not the single aluminum plate slot, bending, and because the bottom is plastic, such as plastic bonding effect Board.

- Q: how would you use aluminum to extract silver from film?just ideas please

- The silver in film is part of a silver salt (silver halides.) It is a very very small amount, probably less than 1 cent worth per roll. You would be a lot better off selling the film than trying to extract the silver from it. If you are hell bent on it, the first step is to expose the film to light. This will break the silver from the halides. Then you can go about trying to figure out how to get the silver apart from the film. I am sure it is possible, but it would involve a lot of work. I imagine you you would spend about $100 on ever $1 worth of silver you could extract.

- Q: What is the cost of an aluminum sheet?

- The cost of an aluminum sheet can vary depending on factors such as size, thickness, and quality. It is recommended to check with suppliers or conduct market research to get accurate and up-to-date pricing information.

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, and this layer can be colored or finished in various ways to achieve different aesthetic and functional results.

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Indeed, kitchen backsplashes can be manufactured using aluminum sheets. Aluminum, being a lightweight and durable material, has commendable resistance against corrosion and heat. Moreover, it is effortlessly cleaned and maintained, making it highly suitable for kitchen usage where splatters and spills are prevalent. The versatility of aluminum sheets allows them to be easily cut and shaped to fit any kitchen size and design, providing ample flexibility in creating personalized backsplashes. Furthermore, aluminum contributes a modern and sleek aesthetic, thus imparting a contemporary touch to the kitchen decor. All in all, opting for aluminum sheets as a manufacturing material for kitchen backsplashes is both practical and stylish.

- Q: How are aluminum sheets cut or shaped?

- Aluminum sheets can be cut or shaped using various methods such as shearing, laser cutting, waterjet cutting, or CNC milling. Shearing involves using a specialized machine to cut the sheet along a straight line. Laser cutting utilizes a high-powered laser beam to precisely cut or engrave the aluminum sheet. Waterjet cutting involves the use of a high-pressure jet of water mixed with an abrasive material to cut through the sheet. Lastly, CNC milling uses computer-controlled machines to remove material from the aluminum sheet and create intricate shapes or designs.

- Q: Can aluminum sheets be used for protective barriers?

- Yes, aluminum sheets can be used for protective barriers. Aluminum is a lightweight and durable material that offers excellent strength and corrosion resistance. It is commonly used in various applications where protection is required, such as construction sites, industrial facilities, and military installations. Aluminum sheets can be easily fabricated and shaped to create sturdy barriers that provide a physical barrier to prevent unauthorized access or to safeguard against potential hazards. Additionally, aluminum is highly versatile and can be combined with other materials, such as glass or steel, to enhance its protective capabilities. Overall, aluminum sheets are a reliable choice for protective barriers due to their strength, durability, and versatility.

- Q: What is the corrosion resistance of aluminum sheets?

- Aluminum sheets possess remarkable resistance to corrosion. When exposed to oxygen, aluminum automatically develops a protective oxide layer on its surface, functioning as a barrier against corrosion. This layer is extremely stable and effectively halts any further oxidation of the metal, resulting in aluminum's exceptional resistance to corrosion in nearly all surroundings. Furthermore, aluminum sheets can be improved even further through surface treatments or coatings to augment their corrosion resistance. As a result, aluminum sheets are widely favored for a multitude of applications in which corrosion resistance is of utmost importance, including the construction industry, automotive manufacturing, and marine applications.

Send your message to us

Industrial Aluminum Foil Sheets - Aluminum Sheet Mill Finished 1060 1050 1100 3003 5005 5052 6061 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords