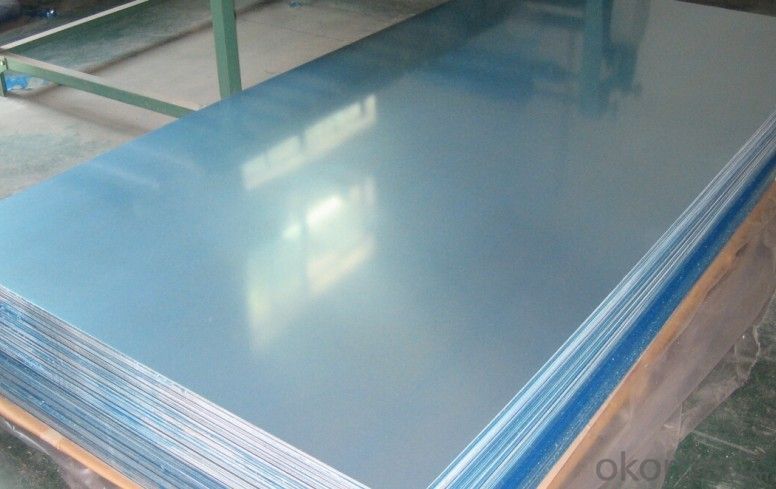

Corrugated Aluminum Sheets - Hot Rolled Anodized Alloy 1060 1070 1050 Thin Aluminum Mirror Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot rolling anodized alloy 1060 1070 1050 thin aluminum mirror sheets

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: Can 101 aluminum sheets be used in the production of decorative panels?

- Indeed, decorative panels can be produced with the use of 101 aluminum sheets. Recognized for its exceptional formability and resistance to corrosion, 101 aluminum stands out as a commercially pure alloy. This alloy's remarkable attributes render it appropriate for diverse applications, decorative panels being one of them. The aluminum sheets have the capacity to be effortlessly molded, trimmed, and crafted, enabling the formation of intricate designs and patterns for ornamental intentions. Furthermore, the corrosion resistance of 101 aluminum guarantees that the panels will retain their visual appeal throughout time, even when exposed to outdoor conditions or environments with high moisture levels.

- Q: This question asks about the impact of using aluminum sheets on the aesthetic appeal of a building.

- <p>Aluminum sheets can significantly enhance the appearance of a building due to their versatility, durability, and modern aesthetic. They offer a sleek, clean look and can be easily shaped into various designs, adding a contemporary feel. The material's resistance to corrosion and weathering ensures that the building maintains its appearance over time. Additionally, aluminum sheets can be coated with various colors and finishes, allowing for customization and the ability to blend with or stand out from the surrounding architecture.</p>

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust. This is because aluminum naturally forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. Unlike iron or steel, which can rust when exposed to moisture and oxygen, aluminum does not require any additional coatings or treatments to protect it from rusting. This makes aluminum sheets a popular choice for a wide range of applications, including construction, automotive, and marine industries, where resistance to rust is essential.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity, low density, and good mechanical properties at low temperatures, making it an ideal choice for applications in cryogenic environments. Additionally, aluminum has a low coefficient of thermal expansion, which allows it to maintain its structural integrity even under extreme temperature fluctuations.

- Q: What are the different methods of surface engraving aluminum sheets?

- Aluminum sheets can be surface engraved using various methods, each with its own unique advantages and suitability for different applications. One method is mechanical engraving, which involves physically removing material from the aluminum sheet using a rotating cutting tool like a milling machine or a router. This precise and versatile technique allows for intricate designs and deep engravings, making it commonly used for signage, branding, and decorative purposes. Another method is laser engraving, a modern and highly precise technique that uses a laser beam to vaporize or melt the surface of the aluminum sheet, creating a permanent mark. With great control over the depth, speed, and intensity of the engraving, laser engraving produces detailed and accurate results. It finds wide application in industries like aerospace, automotive, and electronics for part identification, serial numbers, and barcodes. Chemical etching, also known as chemical milling or photochemical machining, is a process where the aluminum sheet is coated with a photosensitive mask and exposed to UV light through a stencil or artwork. The exposed areas are then chemically etched to create the desired design. Chemical etching offers high precision, repeatability, and the ability to engrave thin lines or complex patterns. It is often used in electronic components, nameplates, and decorative applications. Diamond drag engraving involves using a diamond-tipped stylus to scratch or indent the surface of the aluminum sheet, creating the engraving. This method is commonly employed for industrial applications like part identification and serial numbering, as well as for creating durable and long-lasting markings on aluminum sheets. Lastly, rotary engraving utilizes a rotating cutting tool to remove material from the aluminum sheet, similar to mechanical engraving. However, it is typically used for larger and thicker aluminum sheets and finds application in industrial settings for marking, labeling, and identification purposes. Choosing the appropriate engraving method for aluminum sheets depends on factors such as the desired design, level of detail, durability requirements, and the intended use of the engraved product. Each method offers its own advantages and suitability for different applications.

- Q: Can aluminum sheets be laser cut?

- Yes, aluminum sheets can be laser cut.

- Q: Are aluminum sheets resistant to UV rays?

- Yes, aluminum sheets are generally resistant to UV rays.

- Q: Can aluminum sheets be used for boat building?

- Boat building can indeed incorporate aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored material for constructing boats. Small recreational boats, larger yachts, and even commercial vessels commonly employ aluminum sheets in their construction. These sheets offer numerous benefits, including ease of manipulation, a remarkable strength-to-weight ratio, and minimal upkeep requirements. Furthermore, aluminum boats are esteemed for their exceptional buoyancy, stability, and fuel efficiency. All in all, utilizing aluminum sheets is a suitable and dependable choice for boat building.

- Q: 1995 s10 I took this whole thing apart and marked and labled everything. Now i have an aluminum head sitting on a bucket that was spraying water right from the head gasket but the head gasket is in perfect shape, and there are no cracks i can see on the head. One more thing, the truck would not start up with water in it, but it would when it was drained, like it was blocking the spark or something. yes it did overheat has this ever happened to anyone else, and any ideas? Thank you.

- Check the flatness of the head with a straight edge and feeler gauges, or take it to an automotive machine shop to be checked. The reason overheating causes head gasket leakage is that aluminum expands almost exactly twice as much as iron when heated, so the aluminum heads buckles upward (warps) when it expands too much more than the block. That is why the engine did not fire with coolant in it - the coolant was getting on the spark plug. Eduardo is right about Dex-cool, but your 1995 probably never had it... I believe GM started that debacle in 1996.

- Q: 5052 aluminum plate and LY12 aluminum plate is the same?

- The 5052 series is aluminum magnesium alloy, the magnesium alloy belongs to the lower density alloy, the 5052 alloy aluminum plate density is 2.68

Send your message to us

Corrugated Aluminum Sheets - Hot Rolled Anodized Alloy 1060 1070 1050 Thin Aluminum Mirror Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords