Mill Finish Aluminium Sheet for Shipbuilding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Aluminium Sheet for Shipbuilding

l Other Product Description

1. | Item | Aluminum plate/ Aluminum sheet, aluminium plate price, aluminium chequer plate, aluminium sheet, aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060, 1200, 1100, A1100P, 3003, 3004, 5052, 5652, 5154, 5254, 5454, 5083, 5086, 5056, 5456, 2A21, 2024, 2014, 6061, 6063, 7072, 7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~2200mm | ||

Length | 2m, 3m, 5.8m, 6m or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

11. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

12. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

l Packaging & Delivery

Packaging detail: Export standard package: bundled wooden box, suit for all kinds of transport, or be required.

Delivery detail: about 25 days from received original L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

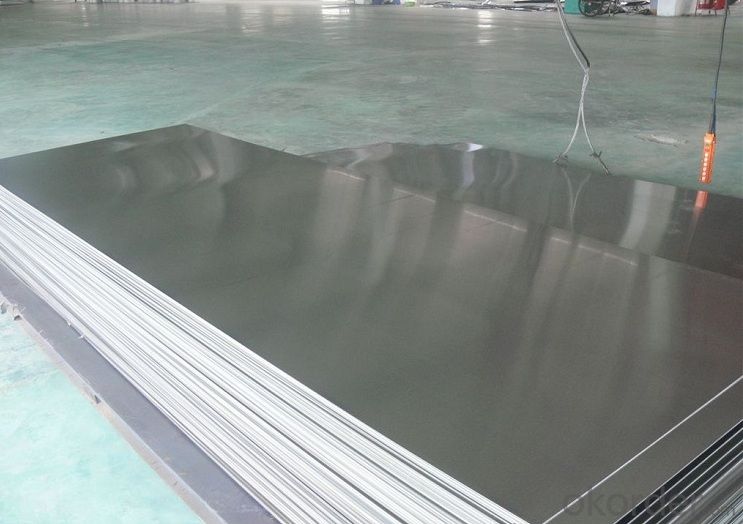

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: This question asks for signs or methods to identify if a building is utilizing aluminum sheets in its construction or design.

- <p>To determine if a building is using aluminum sheets, look for the following signs: 1) Shiny, metallic appearance, which is characteristic of aluminum. 2) Lightweight construction, as aluminum is less dense than many other metals. 3) Resistance to corrosion and weathering, a common feature of aluminum. 4) Use in areas prone to water or moisture, as aluminum is water-resistant. 5) Check for the manufacturer's specifications or building materials list. If possible, consult with the building's architect or engineer for confirmation.</p>

- Q: Can the aluminum sheets be used for manufacturing electronic heat sinks?

- Yes, aluminum sheets can be used for manufacturing electronic heat sinks. Aluminum is a popular choice for heat sink material due to its excellent thermal conductivity and lightweight properties. It efficiently transfers heat away from electronic components, helping to dissipate and manage heat generated during operation. Aluminum sheets can be easily formed and shaped into the desired heat sink design, providing effective cooling for electronic devices.

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a lightweight and durable material that is commonly used in construction due to its corrosion resistance and versatility. It can be easily shaped, cut, and formed into various sizes and designs, making it suitable for creating aesthetically pleasing architectural facades. Additionally, aluminum sheets offer excellent weathering properties, low maintenance requirements, and can be finished with different coatings to enhance their appearance and protection against environmental elements.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ in terms of thickness. Sheets are typically thinner, usually less than 6 mm, while plates are thicker, typically more than 6 mm. Additionally, sheets are often used for lightweight applications such as packaging, whereas plates are commonly utilized for structural purposes or heavy-duty applications.

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: This question asks about the various patterns that can be applied to aluminum sheets, which are commonly used in construction, manufacturing, and design.

- <p>Aluminum sheet patterns are diverse and cater to various applications. Some common types include diamond, checkered, embossed, perforated, and ribbed patterns. Diamond patterns offer a classic look and are slip-resistant, while checkered patterns are often used for flooring due to their traction. Embossed patterns provide a decorative touch and can enhance surface strength. Perforated patterns are used for ventilation, light filtration, and design purposes. Ribbed patterns, also known as corrugated, offer structural strength and are used in roofing and siding applications. Each pattern serves a specific function and aesthetic, making aluminum sheets versatile for many industries.</p>

- Q: I put the aluminum in copper chloride for an experiment and i was wondering if they had different properites.

- Yes, Rust is an Oxide of iron which can be broken down chemically into simpler substances. Aluminium is a pure Element which cannot be broken down chemically or physically into other substances.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- Yes, they were. Aluminum IS a metal. Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray

Send your message to us

Mill Finish Aluminium Sheet for Shipbuilding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords