Mastic PVDF Coated Aluminum Coil - Mill Finished from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

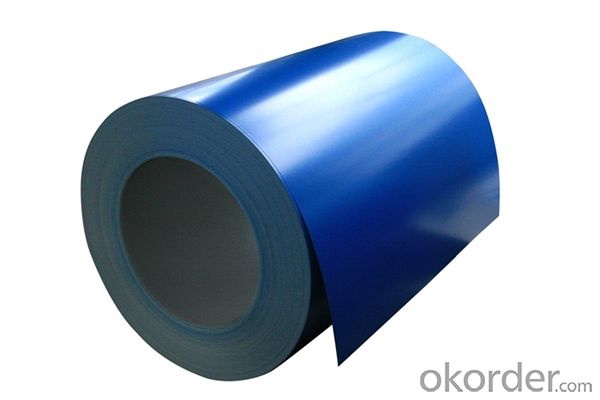

1. Structure of Mill Finished PVDF Coating Aluminium Coil from China Description

Mill Finished PE Coating Aluminium Coil is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PVDF Coating Aluminium Coil from China

Mill Finished PE Coating Aluminium Coil | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

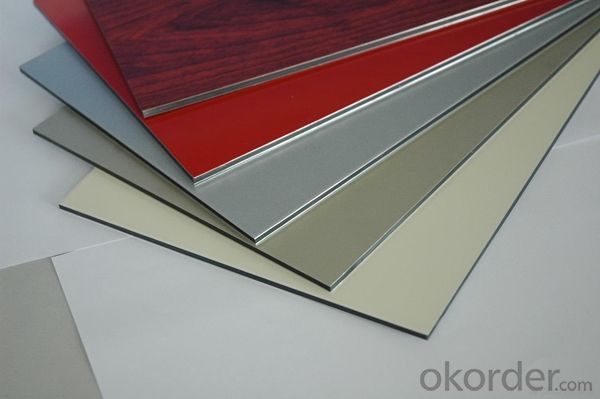

3. Application of Mill Finished PVDF Coating Aluminium Coil from China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PVDF Coating Aluminium Coil from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PVDF Coating Aluminium Coil from China

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Mill Finished PVDF Coating Aluminium Coil from China

7. Package and shipping of Mill Finished PVDF Coating Aluminium Coil from China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it safe and practical to utilize aluminum coils for food storage purposes?

- <p>Aluminum coils can be used for storing food, but it's important to consider the type of food and the conditions. Aluminum is a good conductor of heat, making it suitable for cooking and preserving food in certain contexts, such as in foil form for wrapping food for baking or grilling. However, for long-term storage, especially of acidic or alkaline foods, aluminum may not be ideal due to potential leaching of aluminum into the food, which could be harmful. It's also crucial to ensure that the aluminum is food-grade and not contaminated with harmful substances. For most food storage needs, other materials like glass, stainless steel, or food-grade plastic are often preferred due to their non-reactive nature and safety.</p>

- Q: Difference between aluminium roll gate and iron roll gate

- Structurally, there is no difference, but the aluminum roll gate weight is light, the motor needs little effect, save power; and the iron roll gate weight, motor power, electricity, but the door of high strength, better safety performance.

- Q: Can aluminum coils be used for signage purposes?

- Signage purposes can indeed utilize aluminum coils. Aluminum, as a lightweight and versatile material, finds common use in the signage industry. It possesses exceptional resistance to corrosion, rendering it suitable for both indoor and outdoor applications. Aluminum coils are easily cut and molded into diverse shapes and sizes, enabling the creation of customized signage designs. Moreover, aluminum exhibits high durability and can endure harsh weather conditions, ensuring longevity for signage. Coils can be painted or coated with various finishes to achieve desired aesthetics, while simultaneously safeguarding against fading and scratching. Ultimately, aluminum coils remain a favored choice for signage due to their versatility, durability, and aesthetic appeal.

- Q: How are aluminum coils protected during shipping?

- To guarantee the safety of aluminum coils during shipping and prevent any potential harm, various methods are employed. One frequently used approach involves the utilization of protective packaging materials, such as bubble wrap, foam, or corrugated cardboard, which are employed to envelop the coils. This wrapping creates a cushioning effect that absorbs any impact or vibration that may occur during transportation. In addition to these protective packaging materials, aluminum coils are often placed within robust shipping containers or crates. The design of these containers aims to provide enhanced security and stability during transit, thereby minimizing the risk of the coils being jostled or bumped. Furthermore, to maintain the coils' integrity and decrease the possibility of damage caused by friction with other objects, strapping or banding is frequently employed to secure the coils and prevent any shifting or movement during transportation. Moreover, shipping companies may also employ air-bag systems or dunnage bags to fill any empty spaces within the shipping container. This additional measure further reduces movement and adds an extra layer of protection for the coils. In summary, the protection of aluminum coils during shipping involves a combination of packaging materials, secure containers, and preventive measures to ensure their safe arrival at their intended destination.

- Q: Why do we need aluminum when cooking in the oven at all.

- Keeps the top from getting over cooked and the foil keeps the steam in so your food with be moist.

- Q: This question asks for the most effective methods to clean an aluminum coil, which is a common component in various industries.

- <p>The best ways to clean aluminum coils involve a combination of mechanical and chemical processes. Mechanical cleaning can be done using brushes or pressure washing to remove loose dirt and debris. Chemical cleaning involves using a suitable aluminum cleaner or mild detergent solution to dissolve stubborn grime. Always rinse thoroughly with water to remove any residue. Avoid abrasive materials or harsh chemicals that could scratch the surface. Regular cleaning and maintenance can prevent buildup and extend the coil's lifespan.</p>

- Q: I've heard many times that it's unhealthy to store or cook food in aluminum, due to leaching, but will this apply to handling aluminum. Also, I heard that most aluminum is coated with a layer of something, to prevent oxidation; is this true?

- The food thing is true...don't do that If your talking about Aluminum like in can, rods, screws, etc. Your ok...its an alloy. Now If you talking about Lab quality refined pure Al+3... that oxidizes fast enough that you cam see it turn from silver to white before your eyes. I've seen Pure Al stored in oil filled glasses before, but I used it in small cubes that just had to have the outer layer of oxidized stuff shaved off in oxygen free glove boxes. That stuff might dry your hands a bit. So no worries.

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are certain restrictions on the coil thickness of aluminum coils. The thickness of aluminum coils may vary depending on the specific application and manufacturing process. However, it is generally limited by practical constraints such as the equipment capabilities, handling and transportation considerations, and the desired properties of the final product.

- Q: What are the different coil packaging materials used for aluminum coils?

- Aluminum coils commonly utilize various coil packaging materials to ensure their protection during transportation and storage, guaranteeing their safe arrival at the desired location. Plastic stands out as one of the most favored coil packaging materials for aluminum coils. Plastic packaging can take the form of shrink wrap, stretch film, or plastic bands. Shrink wrap is frequently employed to envelop the coils tightly, providing them with a secure and protective covering. On the other hand, stretch film is used to securely wrap the coils together, preventing any shifting and potential damage. Plastic bands, meanwhile, are used as an additional layer of stability to secure the coils. Paper is another widely used packaging material for aluminum coils. Kraft paper or corrugated cardboard is often utilized to wrap and protect the coils. This type of packaging offers cushioning to prevent the coils from scratching or rubbing against each other during transit. Moreover, paper packaging is easily recyclable, making it an environmentally friendly choice. In addition to plastic and paper, steel strapping is occasionally employed for packaging aluminum coils. Steel strapping possesses excellent strength and durability, ensuring the coils remain securely bundled during transportation. This type of packaging material is particularly valuable for heavy-duty applications that require extra protection. Ultimately, the selection of coil packaging material for aluminum coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. By utilizing the appropriate packaging materials, aluminum coils can be effectively shielded from damage and reach their destination in optimal condition.

- Q: This question asks for a brief explanation of the process involved in manufacturing aluminum coils.

- <p>To make aluminum coil, start with high-quality aluminum ingots. These are melted in a furnace and then poured into a casting machine to create a continuous cast strip. This strip is passed through a series of rollers to reduce its thickness and achieve the desired width and thickness. The rollers apply heat and pressure, gradually forming the aluminum into a coil. The coil is then cooled, often using water, and wound onto a mandrel for storage or further processing. Quality control checks are performed throughout the process to ensure the coil meets specific strength, thickness, and surface finish requirements. The final product is a tightly wound aluminum coil ready for use in various industries such as construction, automotive, and packaging.</p>

Send your message to us

Mastic PVDF Coated Aluminum Coil - Mill Finished from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords